Fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, circuits, etc., can solve problems such as difficult and large-scale pressure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

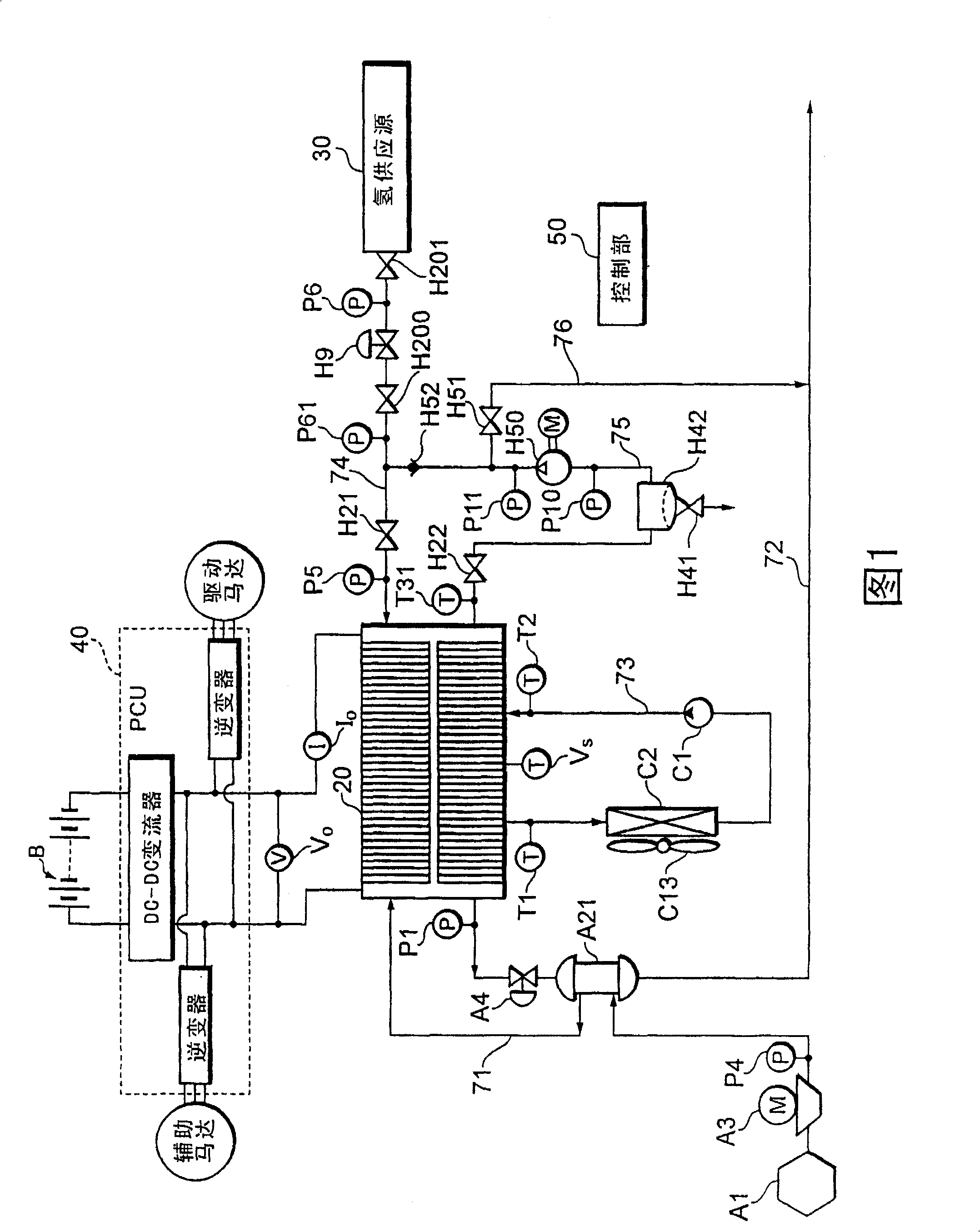

[0045] FIG. 1 shows an example of a fuel cell system to which the first embodiment of the present invention is applied.

[0046] As shown in the figure, air (outside air) as an oxidizing gas is supplied to the air supply port of the fuel cell 20 via the air supply passage 71 . The air supply path 71 is provided with an air filter A1 for removing particulates from the air, a compressor A3 for pressurizing the air, a pressure sensor P4 for detecting the pressure of the supplied air, and a humidifier A21 for adding predetermined moisture to the air. The compressor A3 is driven by an assist motor described later, and constitutes a purification unit together with a control program of the control unit 50 described later. In addition, an air flow meter (flow meter) for detecting the air flow rate is provided in the air filter A1.

[0047] Air off-gas exhausted from the fuel cell 20 is exhausted to the outside through the exhaust passage 72 . The exhaust passage 72 is provided with ...

no. 2 example

[0099]Next, a second embodiment of the present invention will be described with reference to FIG. 11. FIG. In this figure, the parts corresponding to those in FIG. 1 are assigned the same reference numerals, and descriptions of the relevant parts are omitted.

[0100] In this embodiment, the return point of the hydrogen gas from the hydrogen circulation passage 75 is set on the upstream side of the pressure regulating valve H9. The output of the hydrogen pump H50 is regulated by the pressure regulating valve H9. This makes it less likely to be affected by the discharge pressure of the hydrogen pump H50 and its pressure fluctuations. In addition, as in the first embodiment, the pressure of the hydrogen gas supplied to the anode is adjusted by the combination of the pressure regulating valve H9 and the opening degree regulating valve H200. The hydrogen pressure regulation based on various control modes of the opening degree regulating valve H200 as described above can be conti...

no. 3 example

[0102] Fig. 12 shows a third embodiment of the present invention. In this figure, the parts corresponding to those in FIG. 1 are assigned the same reference numerals, and descriptions of the relevant parts are omitted.

[0103] In this embodiment, the pressure regulating valve H9 is replaced with a back pressure valve (back pressure regulating valve) H10. H8 in the figure is a pressure reducing valve. The valve opening degree of the back pressure valve H10 is adjusted so that the downstream side of the back pressure valve H10 becomes a predetermined pressure, and the power generation and discharge of the fuel cell 20 are controlled by adjusting the opening of the opening degree regulating valve H200 provided downstream. Capacity, etc. In addition, the valve opening correction and abnormality judgment of the back pressure valve H10 can be performed on the basis of the opening degree and the secondary pressure of the back pressure valve H10 by the same method as that described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com