Digital type multiple gears synchronous flow-control system

A flow control, multi-gear technology, applied in the flow control of electric devices, etc., can solve the problems of poor control synchronization, secondary pollution, difficult to promote, etc., to avoid secondary pollution of germs, easy to implement, and save water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

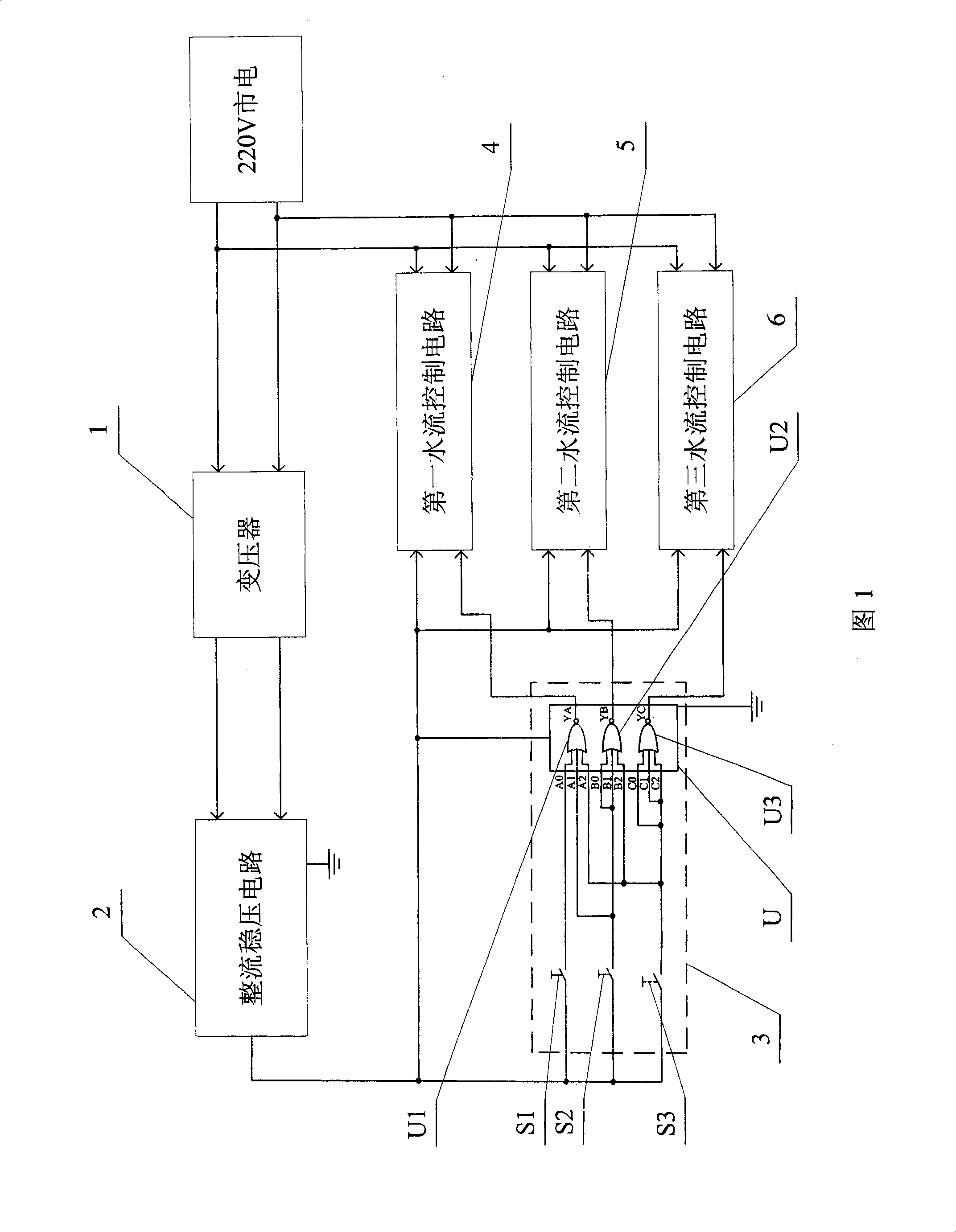

[0006] Specific embodiment 1: Referring to Fig. 1 and Fig. 5, this embodiment consists of a transformer 1, a rectification and voltage stabilization circuit 2, a logic control circuit 3, a first water flow control circuit 4, a second water flow control circuit 5, and a third water flow control circuit 6 Composition, the first power input end of transformer 1 is connected to the first end of 220V mains, the second power input end of transformer 1 is connected to the second end of 220V mains, the first power output end of transformer 1 is connected to rectified and stabilized voltage The first power supply input terminal of the circuit 2 is connected, the second power supply output terminal of the transformer 1 is connected with the second power supply input terminal of the rectification and voltage stabilization circuit 2, the first positive power supply terminal, the second positive power supply terminal, the second positive power supply terminal of the logic control circuit 3 ...

specific Embodiment approach 2

[0008] Specific embodiment two: Referring to Fig. 5, the difference between this embodiment and specific embodiment one is that the rectification and voltage stabilization circuit 2 is composed of a diode rectifier bridge B1, a first filter capacitor C1, a second filter capacitor C2 and a three-terminal voltage regulator The first power input terminal of the diode rectifier bridge B1 is connected to the first power output terminal of the transformer 1, the second power input terminal of the diode rectifier bridge B1 is connected to the second power output terminal of the transformer 1, and the diode rectifier bridge B1 The positive power supply terminal of the three-terminal voltage regulator VR1 is connected to the input terminal Vin of the three-terminal voltage regulator VR1, the negative power supply terminal of the diode rectifier bridge B1 and the ground terminal GND of the three-terminal voltage regulator VR1 are both grounded, and the input terminal Vin of the three-term...

specific Embodiment approach 3

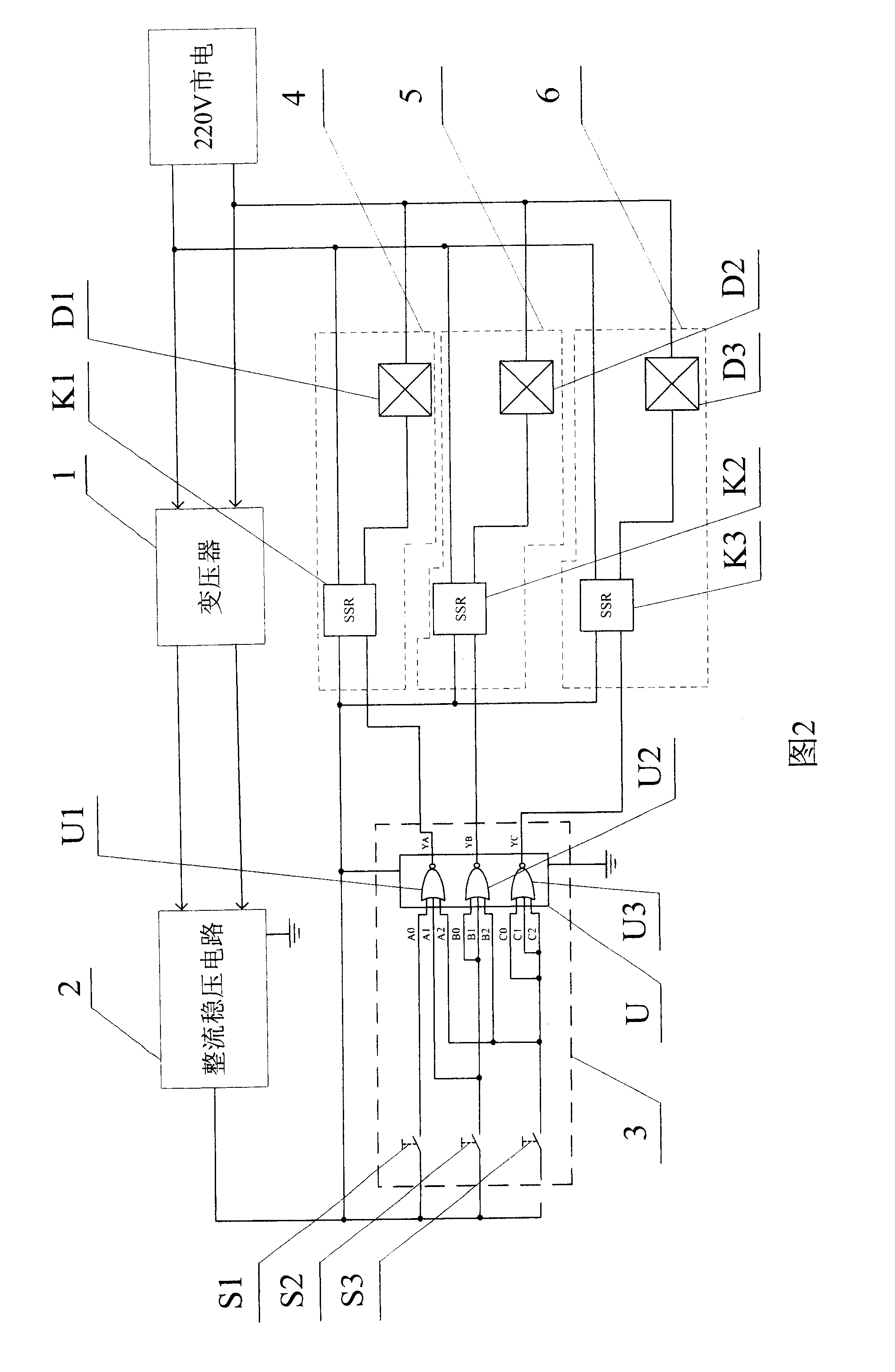

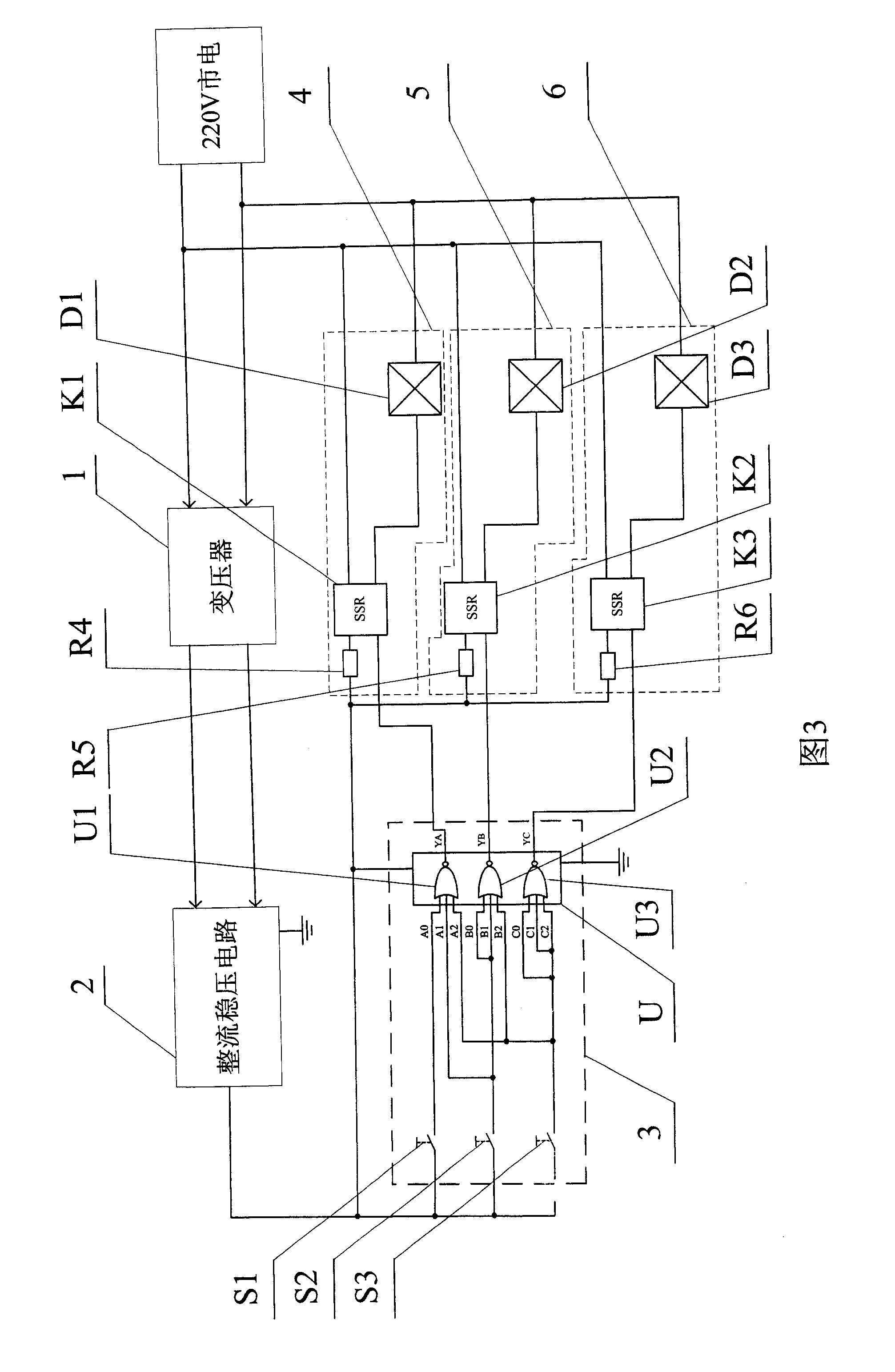

[0010] Specific embodiment three: Referring to Fig. 2, the difference between this embodiment and specific embodiment one is that the first water flow control circuit 4 includes a first solid state relay K1 and a first electromagnetic valve D1, and the first solid state relay K1 The control input terminal is connected to the first control output terminal of the logic control circuit 3, the second control input terminal of the first solid state relay K1 is connected to the positive power supply terminal of the rectification and voltage stabilization circuit 2, and the first power supply input terminal of the first solid state relay K1 Connect to the first end of 220V mains, the second power input end of the first solid state relay K1 is connected to the first power input end of the first solenoid valve D1, the second power input end of the first solenoid valve D1 is connected to the 220V mains The second end connection. Other compositions and connections are the same as in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com