Equipment head for lifting, transporting and placing components

A technology of structural components and assembly heads, applied in the direction of electrical components, electrical components, etc., can solve problems such as vibration of linear motors and components fixed on it, reduce mechanical vibration, maintain assembly accuracy, and increase assembly speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

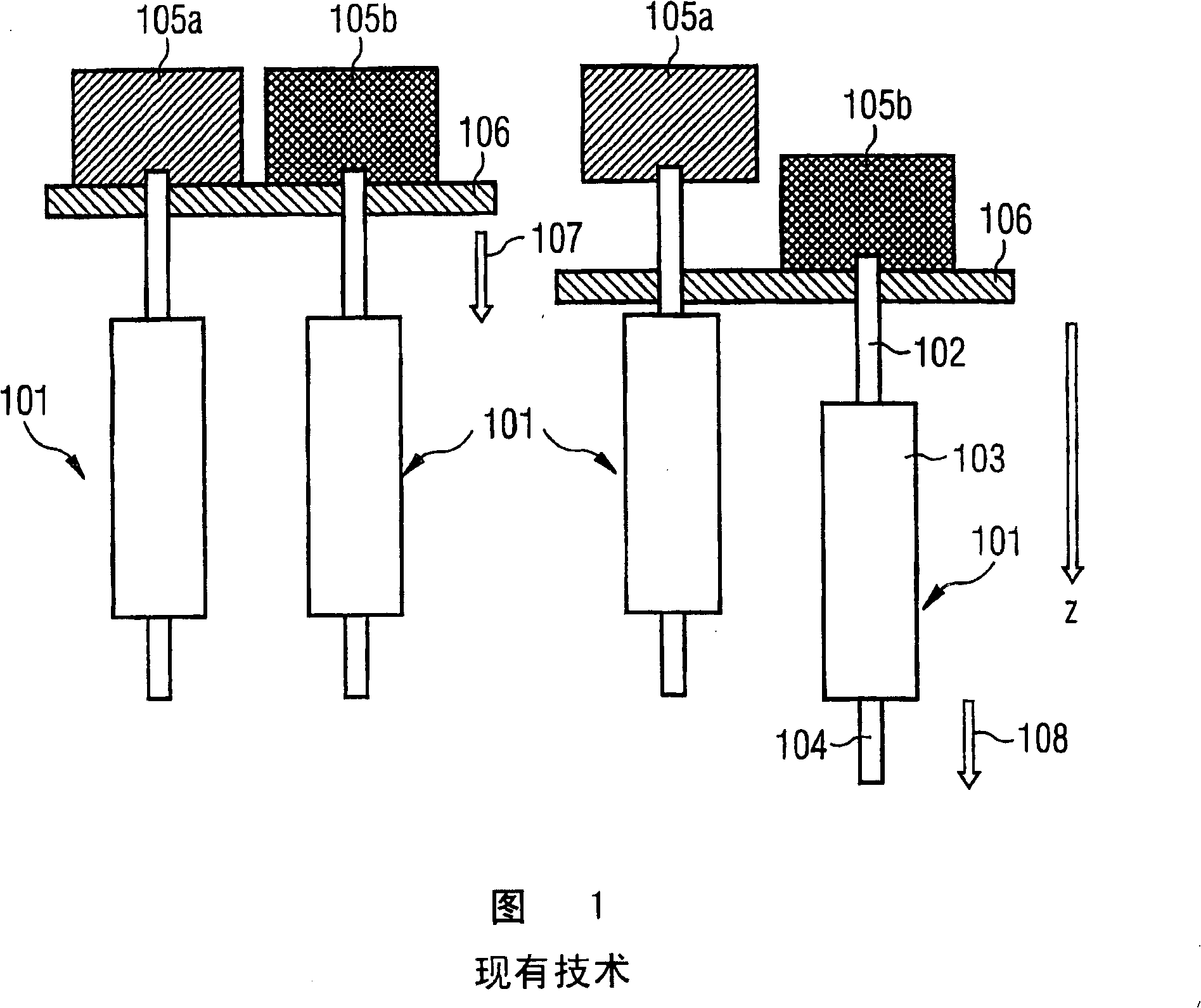

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

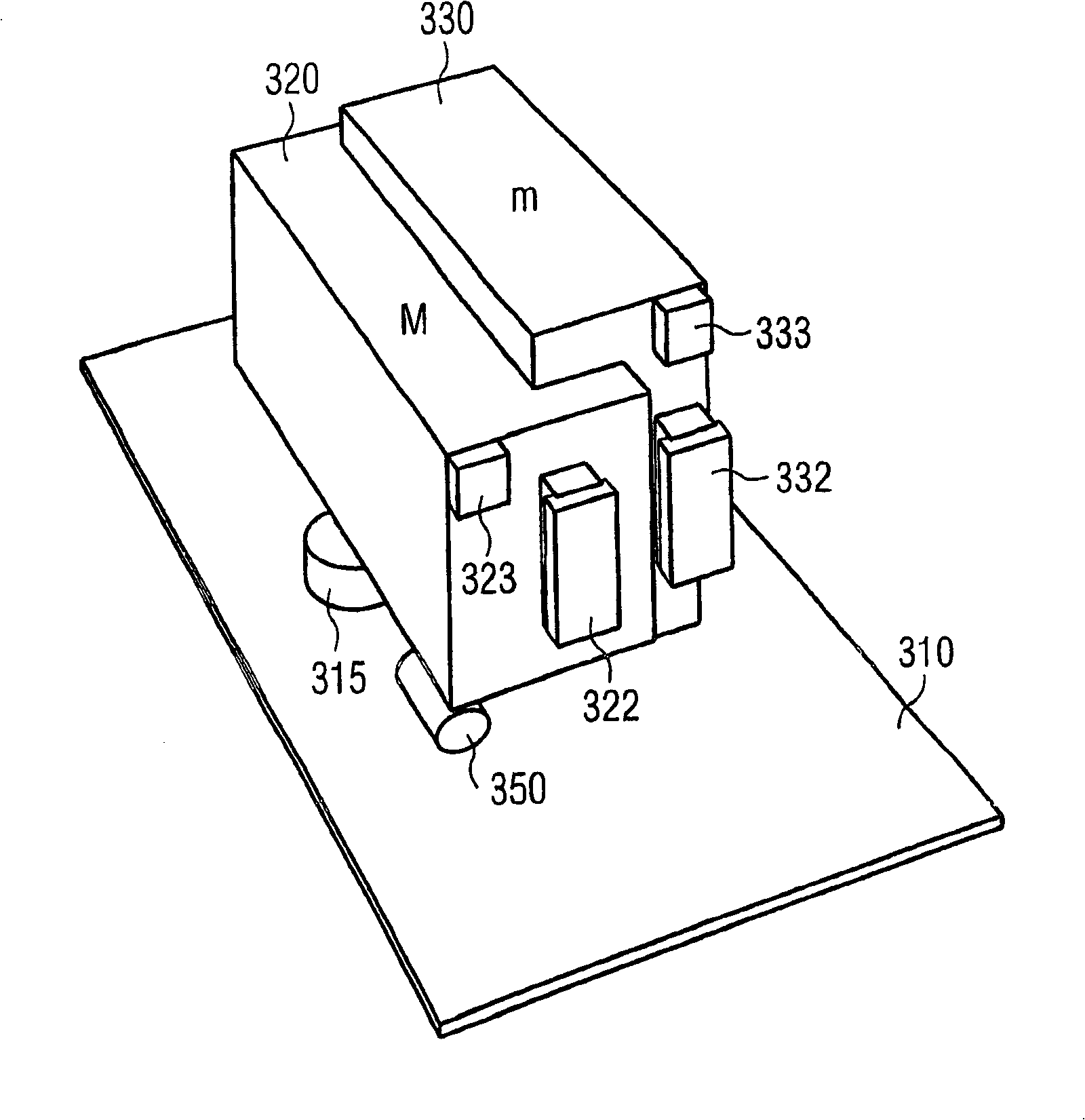

[0043] It should be noted here that the reference signs of mutually corresponding components differ only in their first digits.

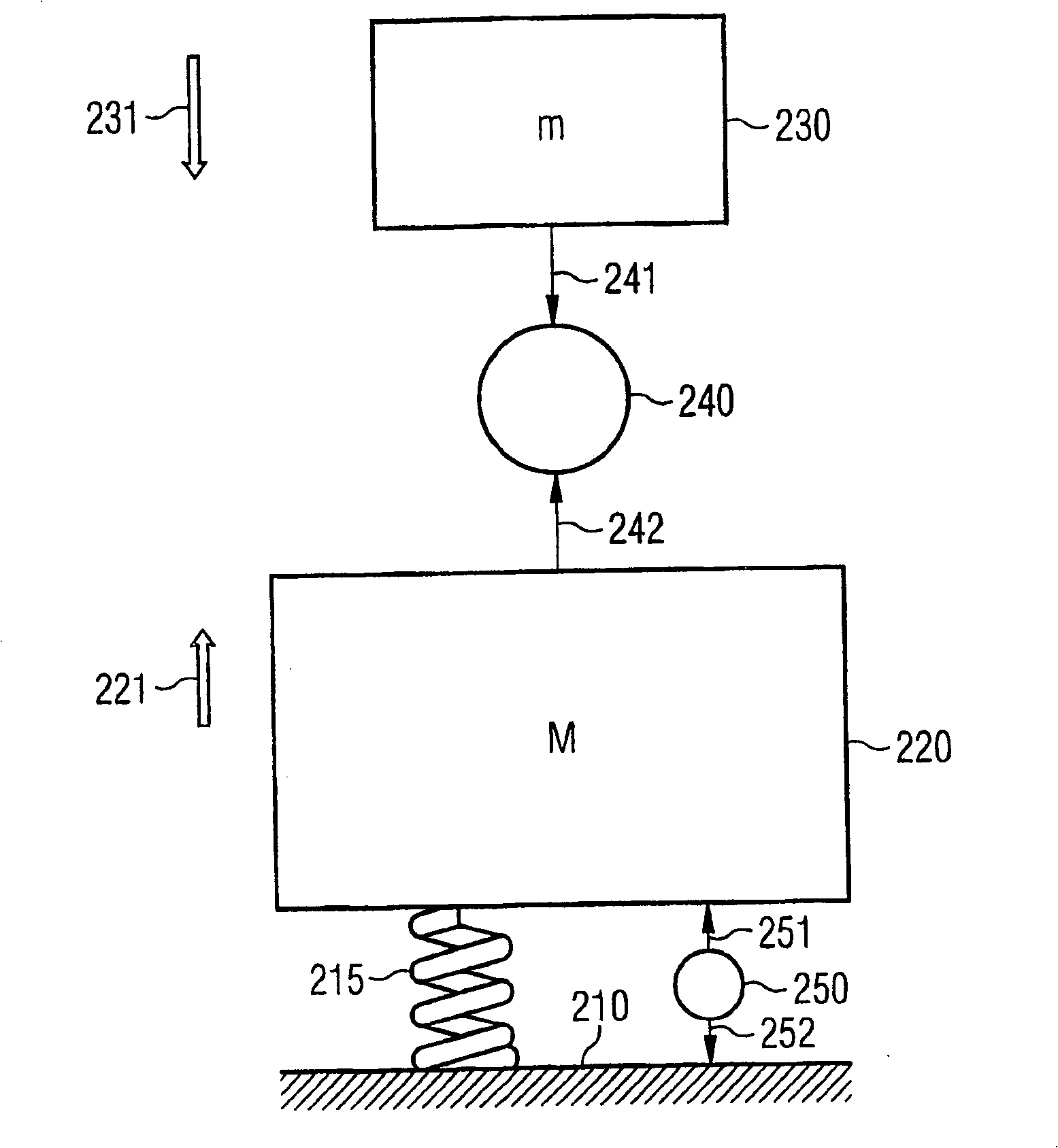

[0044] as by figure 2 As can be seen from the shown block diagram, a stator 220 of a linear motor is mechanically connected via a spring structure 215 to a base body 210 of the assembly head. In addition to the stator 220 , the linear motor also includes a mover 230 . The mechanical connection between stator 220 and mover 230 is schematically indicated by a linear drive 240 .

[0045] Next, explain the situation that the mover 230 moves downward due to the force and reaction force generated when the linear motor moves. In this case, the linear drive 240 induces a force 241 which acts on the mover 230 and pulls this downwards. Wherein, according to the principle of Newton's law that the action force and the reaction force are equal, a reaction force 242 is generated, which acts on the stator 220 and pulls it upward. Due to the force effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com