Method of realizing local crest welding and printed circuit board

A printed circuit board and wave soldering technology, which is applied to the implementation method of partial wave soldering and the field of printed circuit boards, can solve the problems of complex spacing and other problems, and achieve the effects of widening the application range, low cost, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

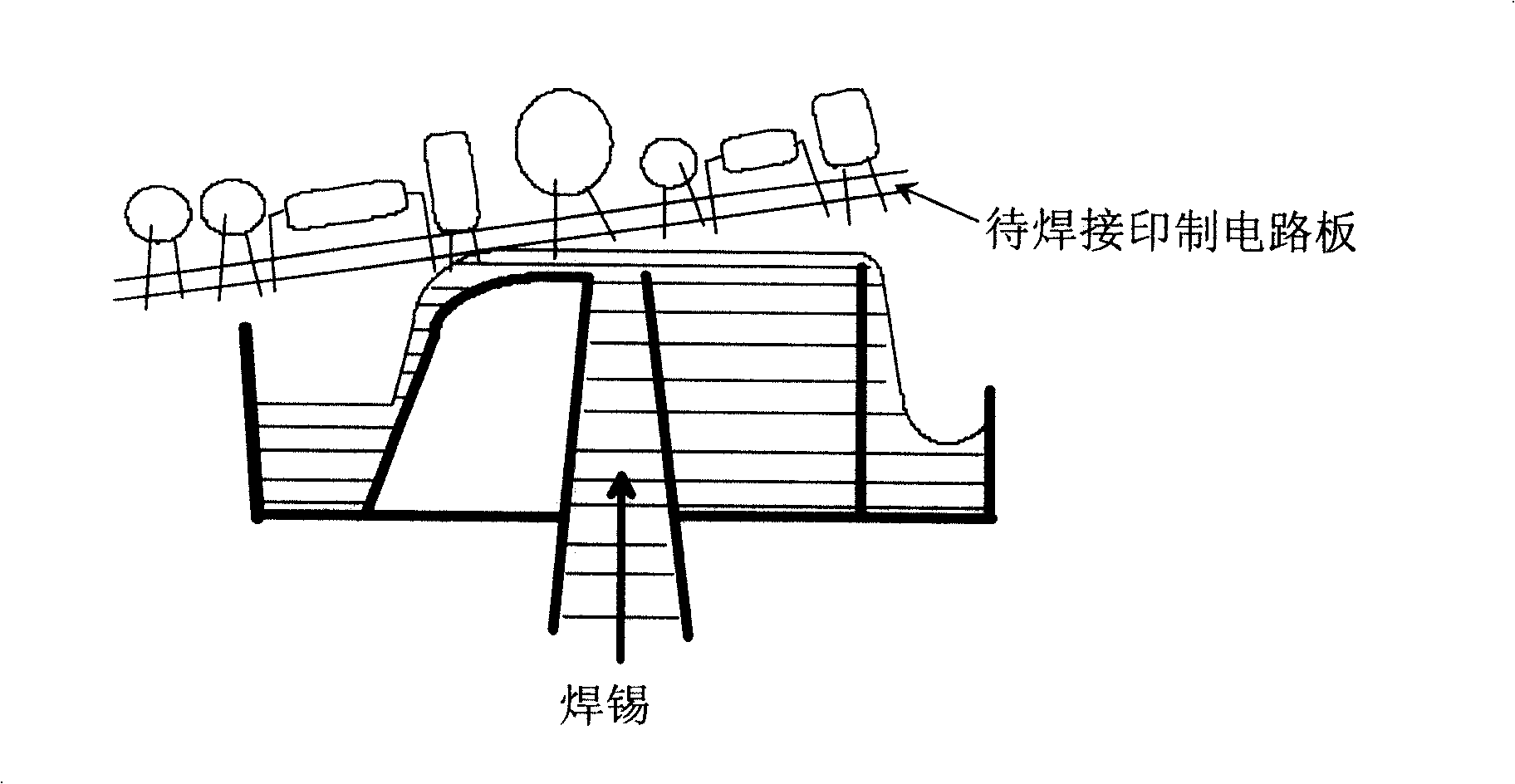

[0037] refer to Figure 4 As shown, the printed circuit board (referred to as PCB) includes devices such as surface mount devices and plug-ins. The device layout on the soldering surface of the PCB is divided into two areas: the surface mount device (referred to as SMD) area and the plug-in area. No SMD devices are included in the rear plug-in area, and as few plug-in devices as possible are laid out in the SMD area.

[0038] The SMD area and the plug-in area maintain a boundary width of 5-10mm, which is determined according to the specific wave soldering equipment capability.

[0039] There is a boundary line between the plug-in area and the SMD area, and the boundary line can also be an area with a certain width without devices. The dividing line should be parallel to the edge of the wave soldering track transfer plate.

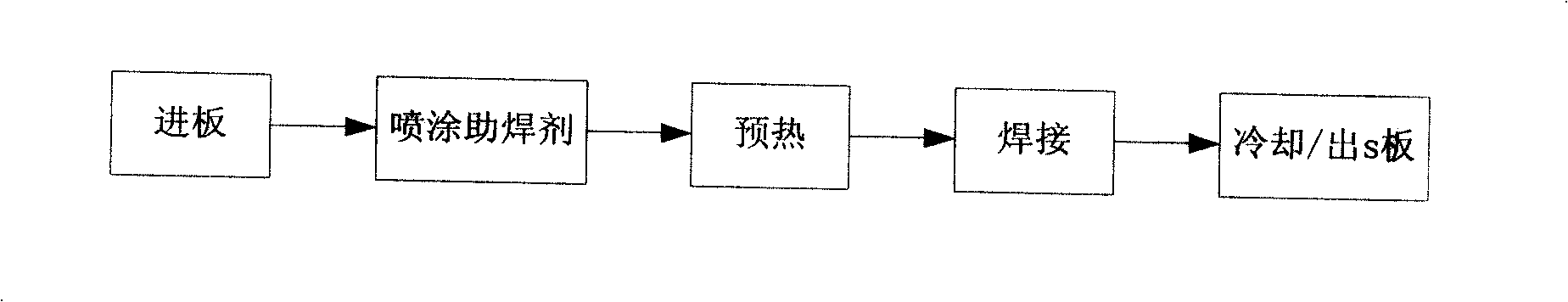

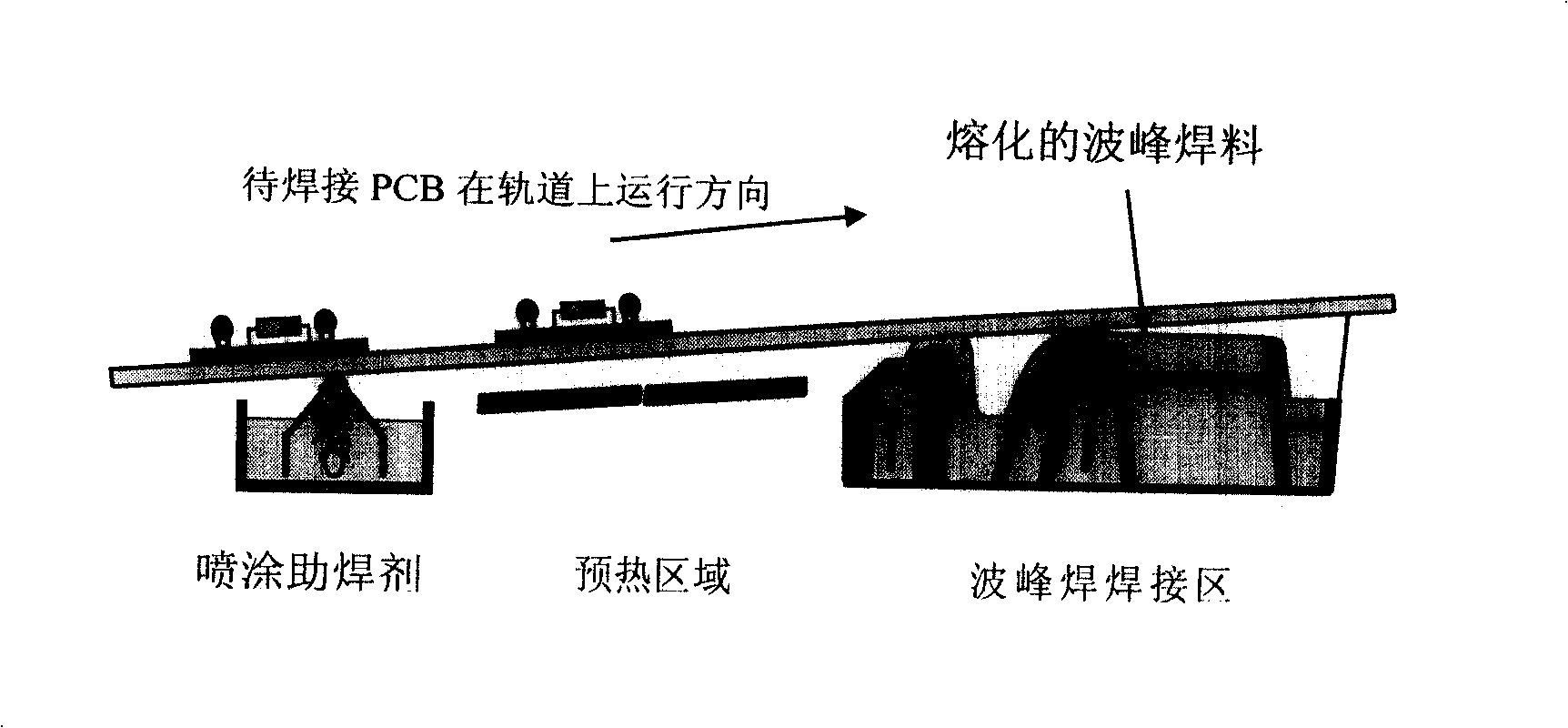

[0040] In order to achieve partial wave soldering, simple improvements to conventional wave soldering equipment are required.

[0041] refer to Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com