Silicon sheet pre-positioning system based on multiple sensor data fusing

A data fusion, multi-sensor technology, applied in the system field of semiconductor lithography technology, can solve the problems of CCD sensor space size unable to meet requirements, limited space for accuracy improvement, low sensor sampling frequency, etc., to achieve high repeatability accuracy, The effect of improving accuracy and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

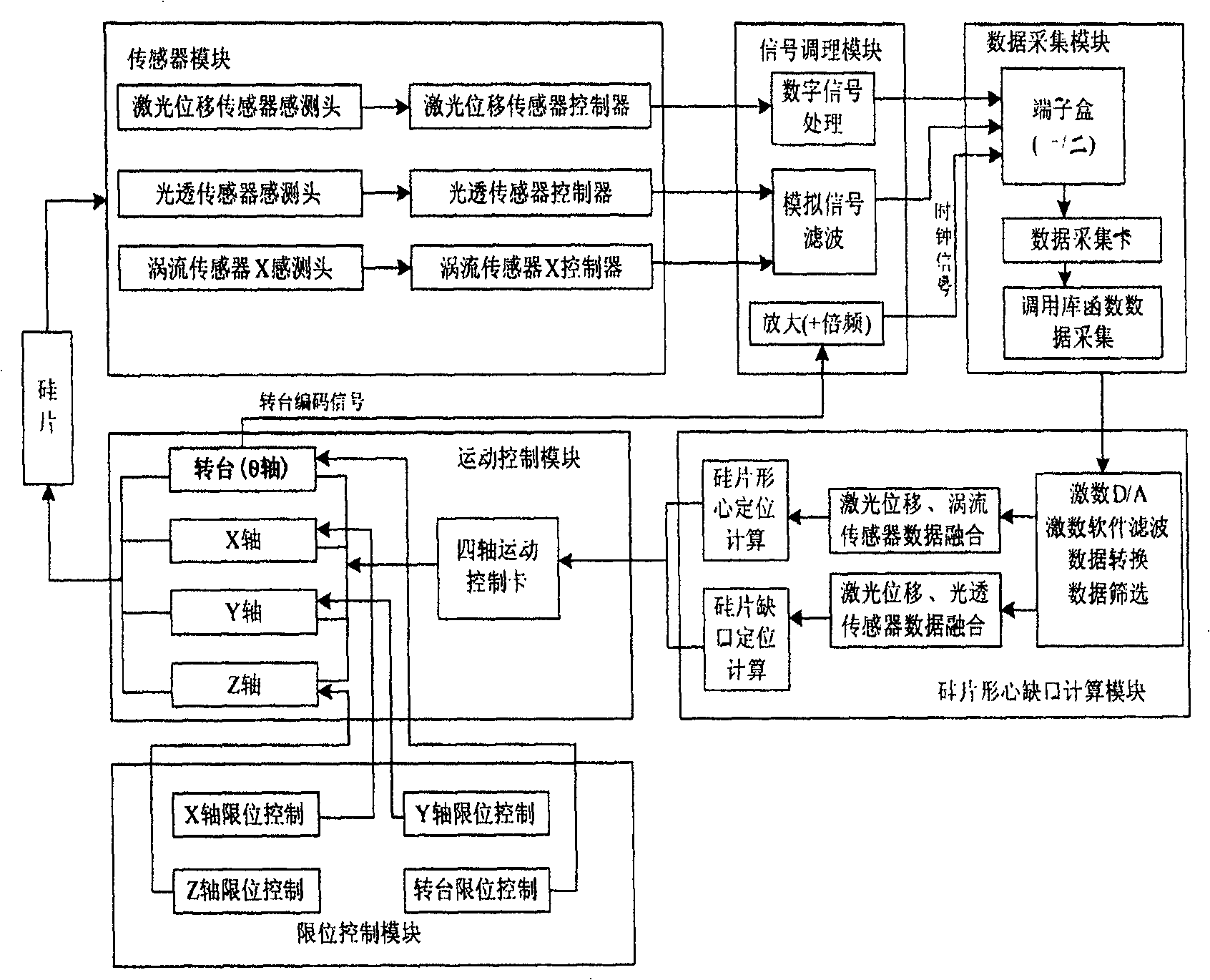

[0020] Such as figure 1 As shown, this embodiment includes six modules: a sensor module, a signal conditioning module, a data acquisition module, a silicon wafer centroid gap calculation module, a motion control module, and a limit control module. The sensor module connects the detected silicon chip information to the signal conditioning module, the signal conditioning module recuperates the silicon chip information after receiving it, the conditioned signal is connected to the data acquisition module, and the data acquisition module converts the signal conditioned by the signal condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com