Double pony truck container crane capable of hoisting two 40-feet containers simultaneously

A technology of container cranes and double trolleys, which is applied in the direction of trolley cranes, cranes, transportation and packaging, etc., can solve the problems affecting the productivity of container cranes, solve the problem of anti-sway loading and unloading positioning, improve loading and unloading efficiency, and increase loading and unloading speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

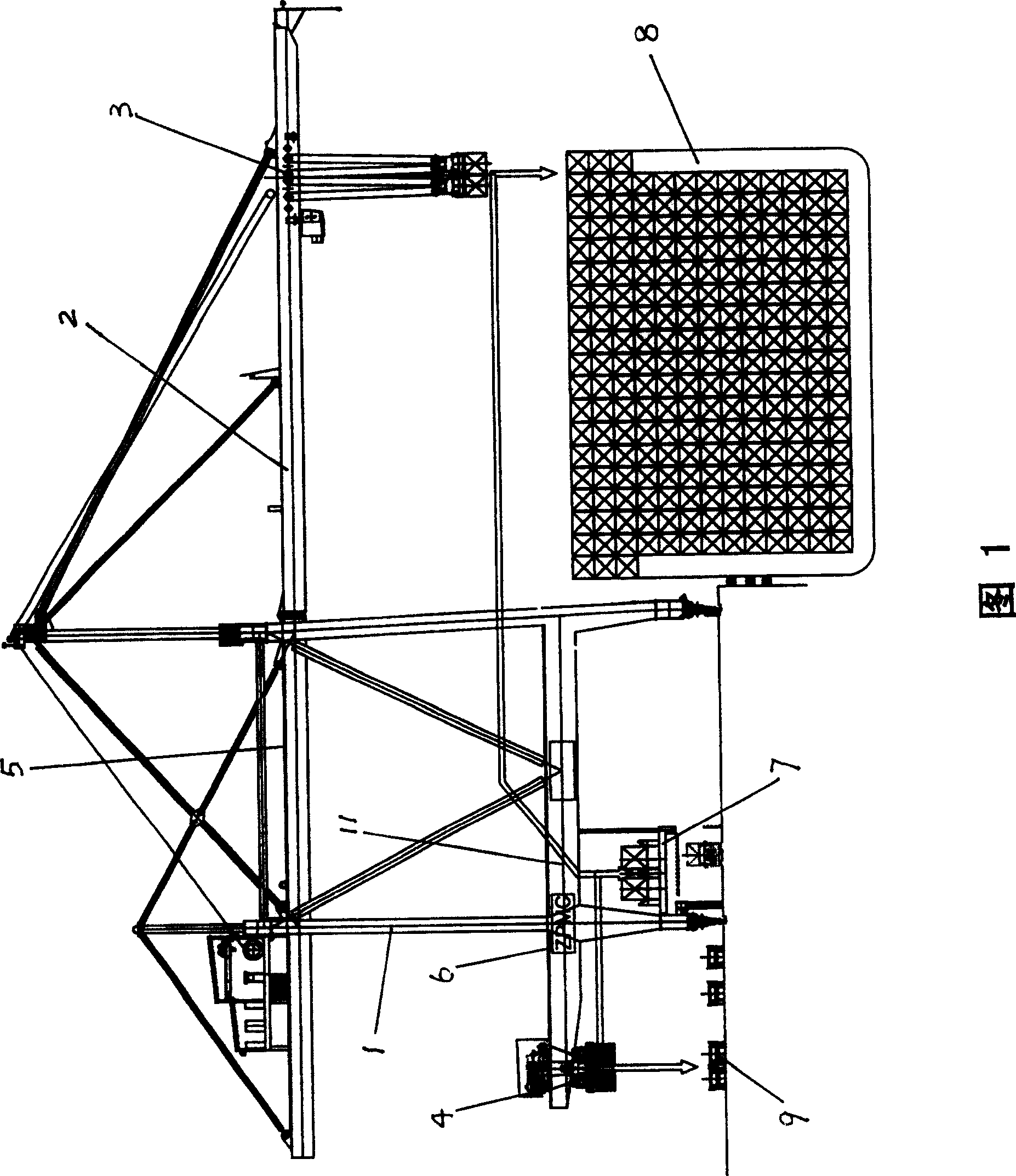

[0014] Referring to Fig. 1, the double trolley container crane that can lift double 40-foot boxes simultaneously in the present invention includes a door frame 1, a girder 2 erected above it, a front trolley 3 and a rear trolley 4, a group of rails 5 are arranged on the girder, and a set of rails 5 are arranged on the gate frame. A group of tracks 6 are arranged on the crossbeam, and a container transfer platform 7 is arranged below the doorframe crossbeam.

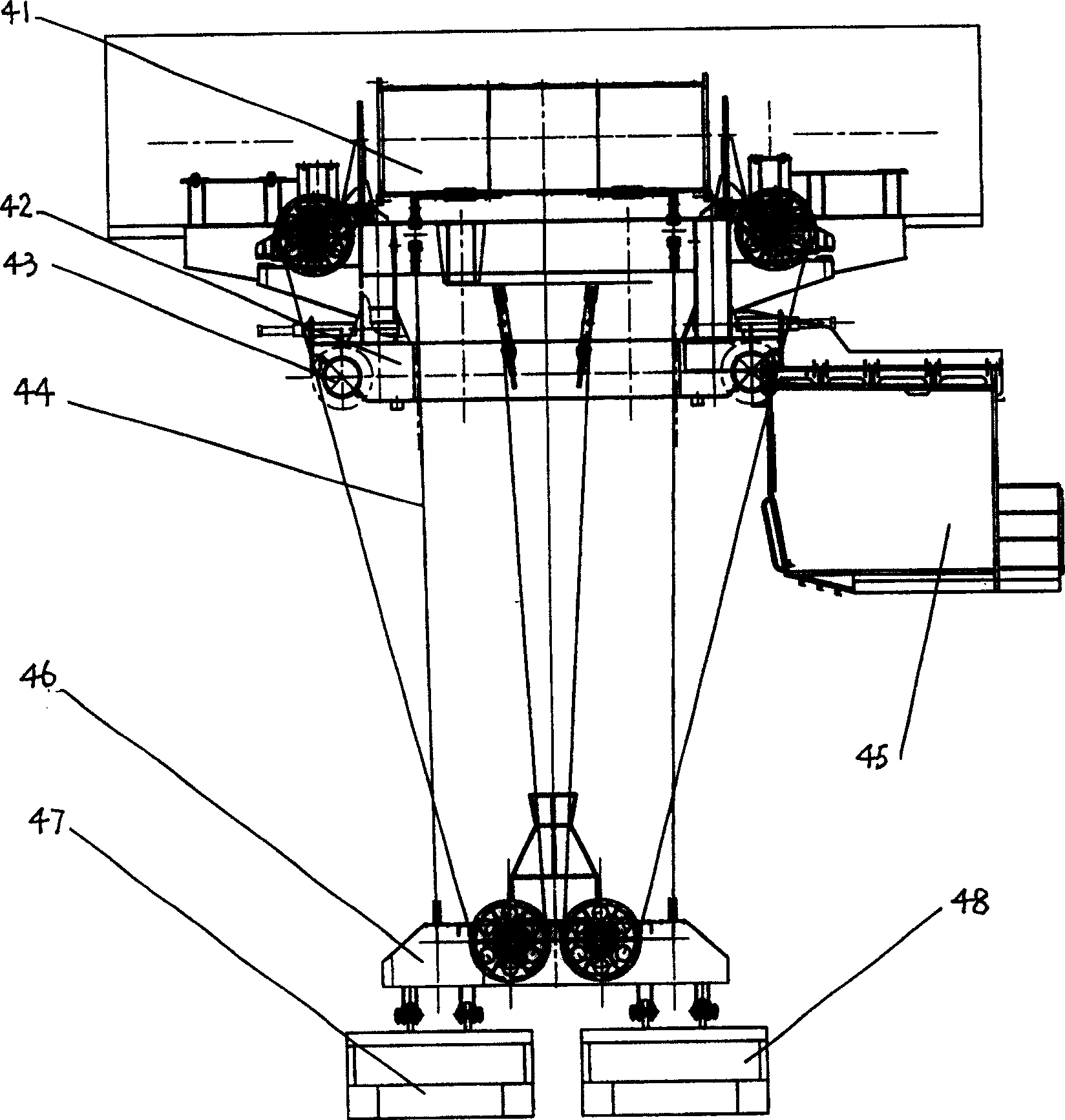

[0015] The working principles of the front and rear trolleys in the present invention are similar, and each includes a hoisting mechanism, a trolley frame, a trolley running mechanism, a wire rope winding mechanism, a driver's cab and a set of spreader systems. by figure 2 The shown rear trolley 4 is an example, the rear trolley 4 includes a lifting mechanism 41, a trolley frame 42, a trolley running mechanism 43, a wire rope winding mechanism 44, a driver's cab 45 and a spreader system, and the spreader system includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com