A liquid supply component assisted with a spray gun and a liquid supply method thereof

A liquid supply component and liquid technology, applied in the direction of liquid injection devices, injection devices, etc., can solve problems such as pipeline blockage and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

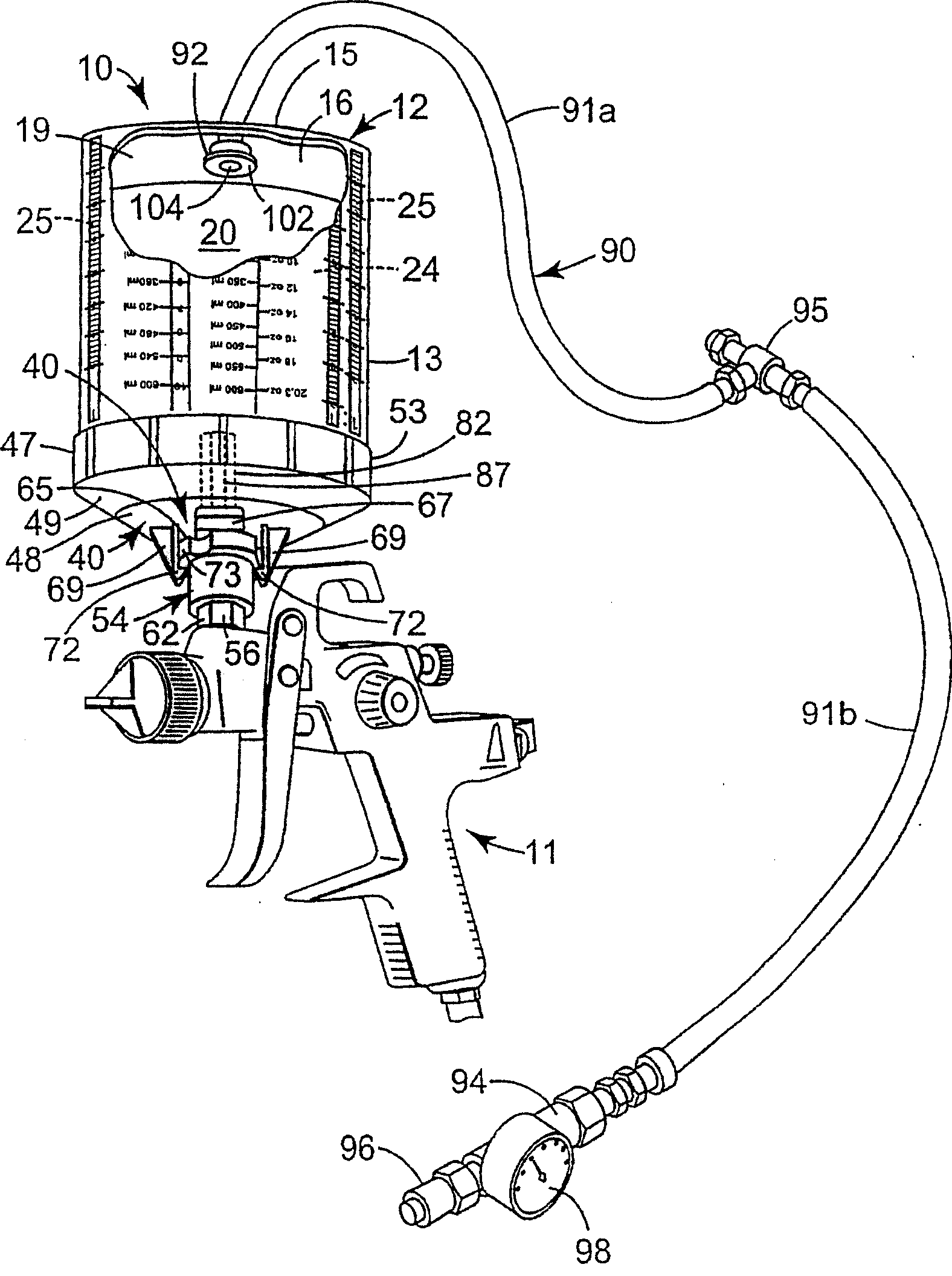

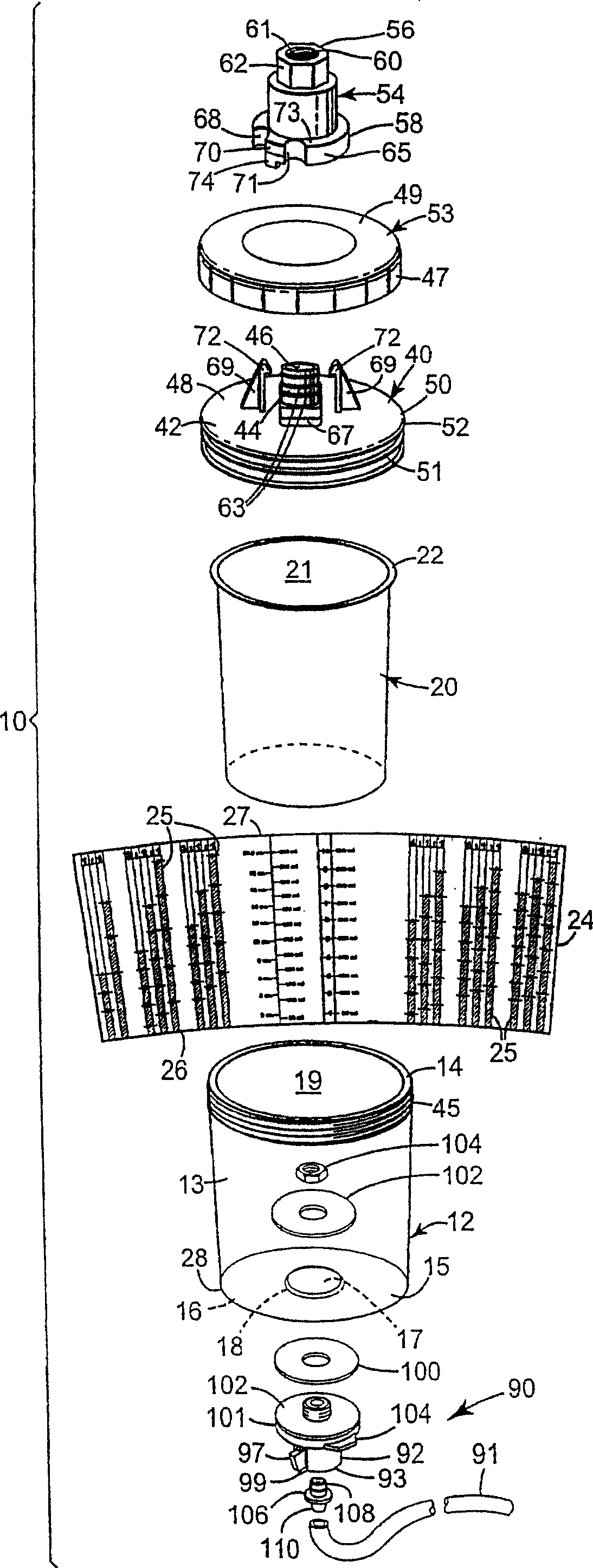

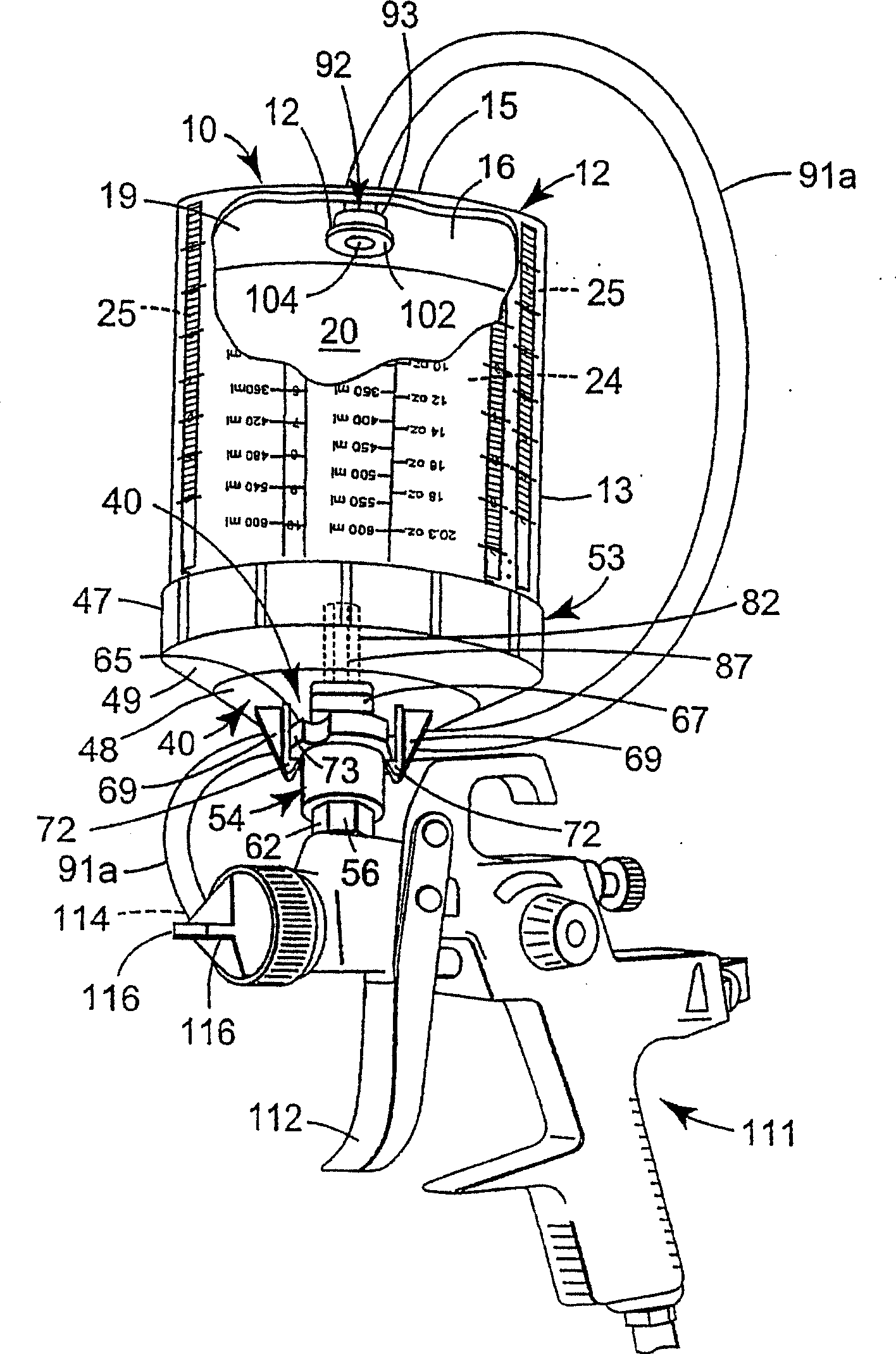

[0017] see now figure 1 and 2 , shows a liquid supply assembly according to the present invention, which is generally indicated by reference numeral 10 . Such as figure 1 As shown, the liquid supply assembly 10 can be used to supply the liquid to be sprayed to a conventional gravity-fed liquid spraying device or spray gun 11, such as the illustrated spray gun 11, which is commercially known as "SATA" (t.m.) NR -95" and are available from Sata, Farbspritzenchnik Gmbh & Co., Kornwestheim, Germany.

[0018] The liquid supply assembly 10 includes a container 12 made of a rigid polymeric material that appears transparent, such as injection molded clear clear polypropylene to have walls about 0.047 inches or 1.2 millimeters thick. The container 12 includes a generally cylindrical side wall 13 having top and bottom ends 14 and 15 , and a bottom wall 16 extending across the bottom end 15 of the side wall 13 . The bottom wall 16 has a central circular opening 17 around which an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com