High-nickel ternary precursor with polycrystalline structure and preparation method of high-nickel ternary precursor

A polycrystalline structure and precursor technology, applied in structural parts, chemical instruments and methods, nickel compounds, etc., can solve the problems of limited improvement of material properties, and achieve the goal of strengthening order, improving cycle stability, and improving surface activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

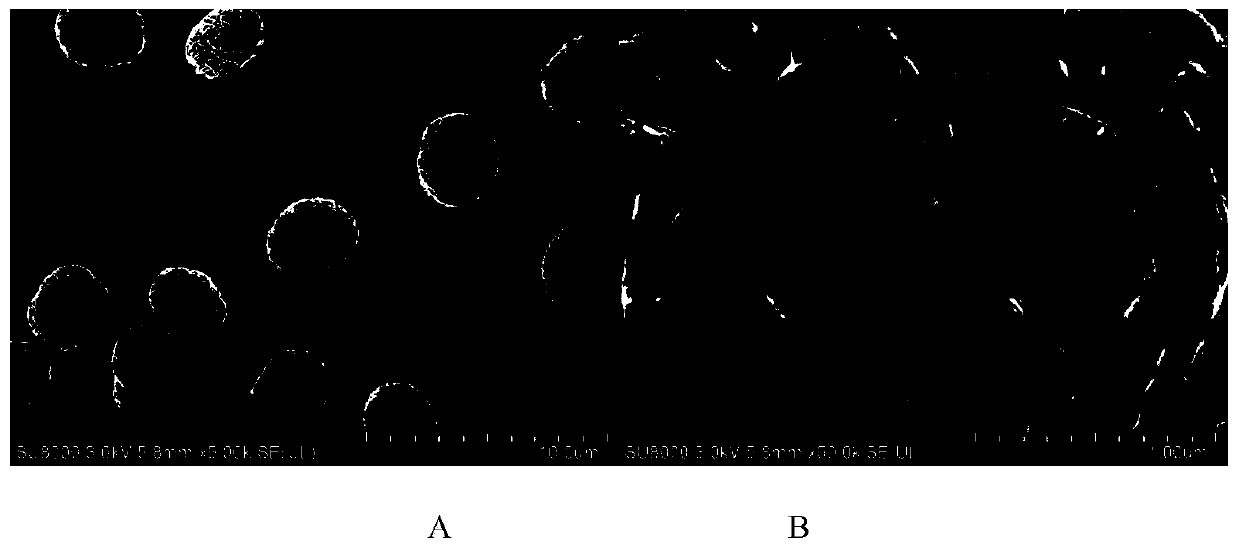

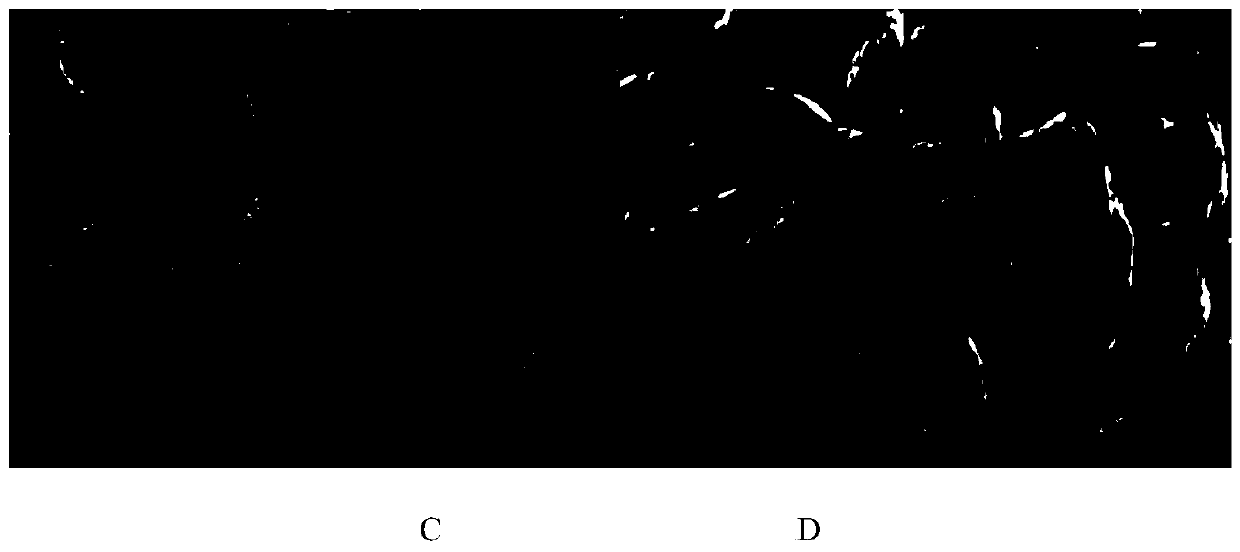

Embodiment 1

[0042] Prepare the aqueous solution of nickel-cobalt-manganese salt, the mol ratio of nickel-cobalt-manganese is 83:11:6, it is mixed with ammonia solution, sodium hydroxide solution and flow into the 20L reaction kettle that bottom liquid is arranged, make three kinds of metals of nickel-cobalt-manganese The total molar concentration of ions is 2mol / L, and the inert gas N is introduced at the same time 2 Protection, the first stage: pH1=10.7, ammonia concentration C1=10g / L, reaction time t1=20h, rotation speed 600rpm, reaction temperature 50°C, particle size D50 =4um, the ratio of the axial thickness to the radial length of the secondary accumulation particles is 0.27; the second stage: the pH is increased to pH2=11.3, the concentration of ammonia water C2=7g / L, and the reaction is continued for 15h, the particle size is D 50 =7.8um, the ratio of the axial thickness to the radial length of the secondary accumulation particles is 0.36; the third stage: continue to adjust the pH...

Embodiment 2

[0045] Prepare the aqueous solution of nickel-cobalt-manganese salt, the mol ratio of nickel-cobalt-manganese is 88:9:3, it is mixed with ammonia solution, sodium hydroxide solution and flow into the 20L reaction kettle that bottom liquid is arranged, make three kinds of metals of nickel-cobalt-manganese The total molar concentration of ions is 1mol / L, and the inert gas N is introduced at the same time 2 Protection, pH1=11, ammonia concentration C1=14g / L, reaction time t1=20h, rotation speed 400rpm, reaction temperature 50°C, particle size D 50 =4.5um, the ratio of the axial thickness to the radial length of the secondary accumulation particles is 0.22; raise the pH to pH2=11.45, the concentration of ammonia water C2=6.5g / L, continue to react for 10h, the particle size is D 50 =8um, the ratio of axial thickness to radial length of the secondary accumulation particles is 0.36; continue to adjust the pH to pH3=11.6, ammonia water concentration C3=4.5g / L, continue to react for 15...

Embodiment 3

[0048] Prepare the aqueous solution of nickel-cobalt-manganese salt, the mol ratio of nickel-cobalt-manganese is 80:10:10, it is mixed with ammonia solution, sodium hydroxide solution and flow into the 20L reactor that bottom liquid is arranged, make three kinds of metals of nickel-cobalt-manganese The total molar concentration of ions is 2.5mol / L, and the inert gas N is introduced at the same time 2 Protection, the first stage: pH1=10.8, ammonia concentration C1=11g / L, reaction time t1=18h, rotation speed 700rpm, reaction temperature 55°C, particle size D 50 =4um, the ratio of the axial thickness to the radial length of the secondary accumulation particles is 0.32; the second stage: increase the pH to pH2=11.4, ammonia concentration C2=7.5g / L, continue to react for 15h, particle size D 50 =7.8um, the ratio of the axial thickness to the radial length of the secondary accumulation particles is 0.4; the third stage: continue to adjust the pH to pH3=11.7, the concentration of amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com