Mobile wood crusher

A mobile, crusher technology, applied in grain processing, etc., can solve problems such as inability to clean, reduce operability, and wood chip interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] An embodiment of the present invention will be described below with reference to the drawings.

[0124] [1]. Overall composition

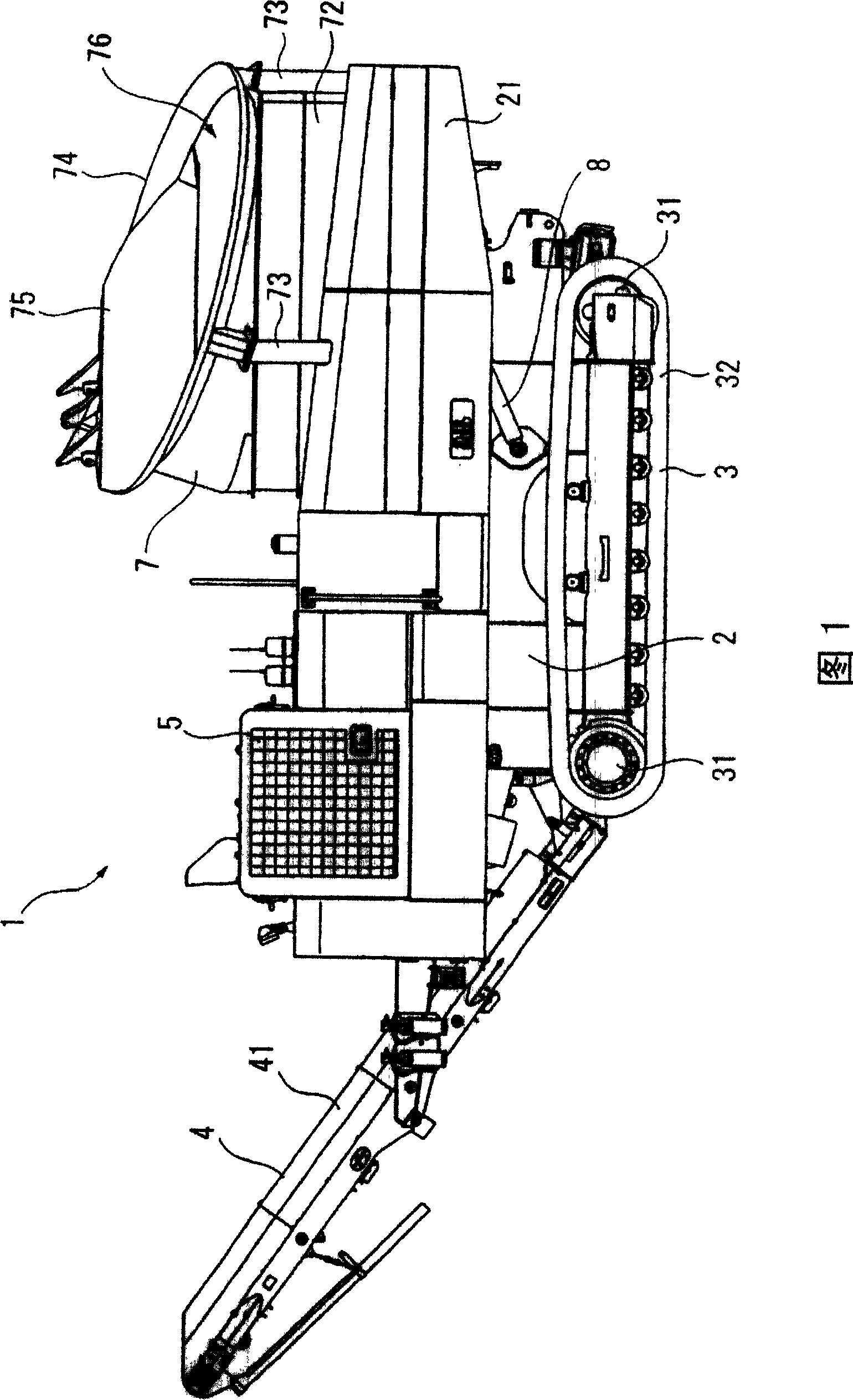

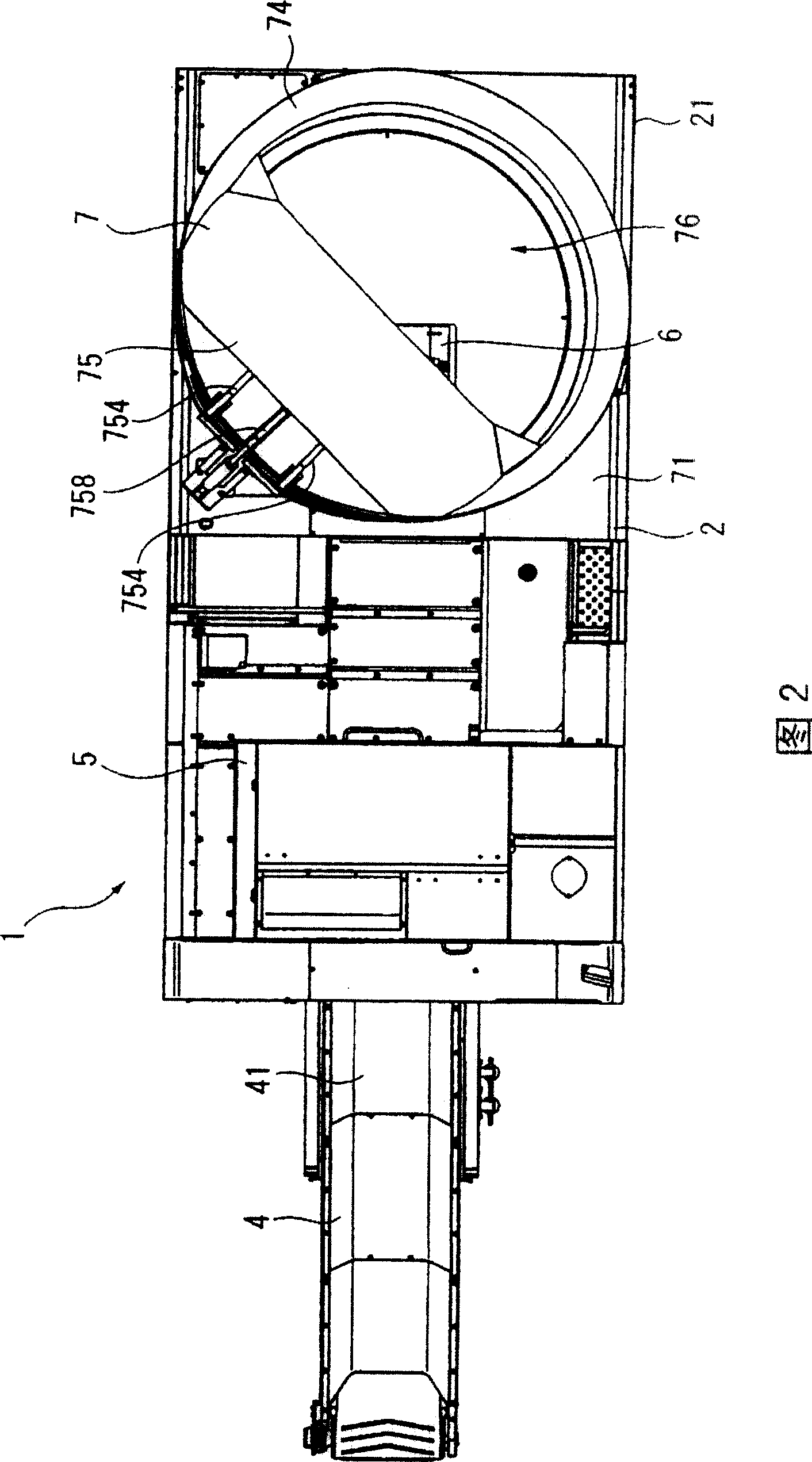

[0125] Figure 1~ image 3 In , the mobile wood chipper 1 according to the embodiment of the present invention is shown. This mobile wood chipper 1 includes a vehicle body 2, a traveling device 3, a conveyor belt 4 as an unloading device, a driving device 5, a rotary crushing device 6, and a vane type supply device 7. When the wood is used, the wood is broken by the rotary crushing device 6, and the broken wood fragments are discharged to the outside by the conveyor belt 4.

[0126] The car body 2 is made of a steel frame, and supports the conveyor belt 4 , the driving device 5 , the rotary crushing device 6 and the vane type feeding device 7 . Furthermore, the vane type supply device 7 is supported by a swing mechanism 8 provided on the vehicle body 2 , and the outside of the vane type supply device 7 is covered by a device cover 21 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com