Method for making two-frequency high temperature grating

A manufacturing method and dual-frequency grating technology, applied in the field of photometric mechanics, can solve problems such as complex optical paths, many optical elements, and difficult manufacturing, and achieve the effect of simple process and variable depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

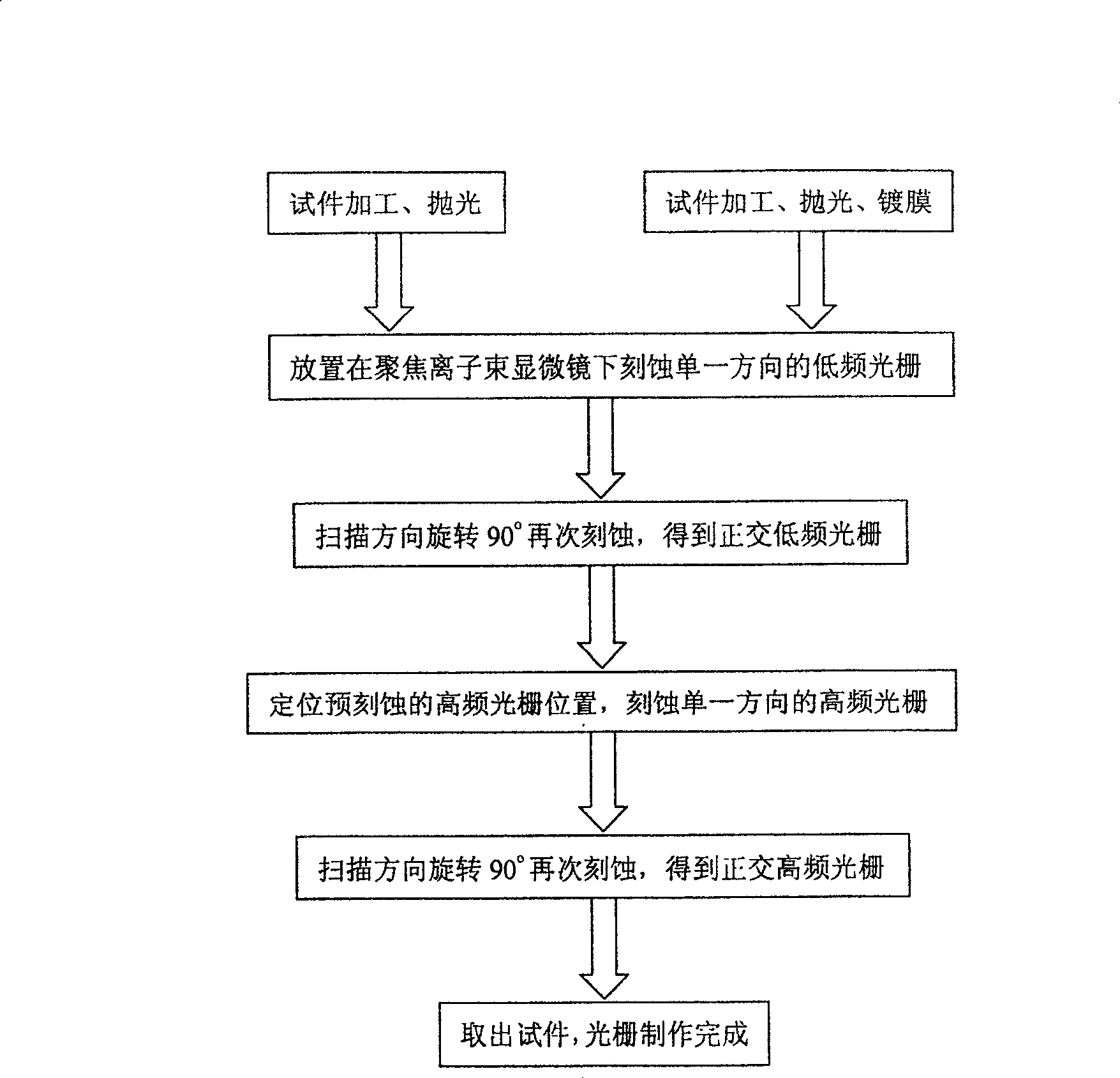

Method used

Image

Examples

Embodiment 1

[0019] The material of the test piece is TiNi shape memory alloy, which is processed by electric cutting, and then polished by hand, and a layer of gold film is plated on the surface of the test piece with a thickness of 0.5 μm.

[0020] This test piece is placed on the stage of the focused ion beam microscope that the model is DB235, makes the side that is coated with gold film face up, selects acceleration voltage U=30kv, beam intensity I=400pA, etching depth Z= 0.4μm, the magnification is 12000 times, select the orthogonal parallel line pattern, set the line spacing to 0.4μm, etch after the focus is clear, and obtain an orthogonal grating of 2500l / mm. Then use the positioning system to move to the position of the pre-etched high-frequency grating (a certain area on the low-frequency grating), set the etching parameters of the 5000l / mm orthogonal grating, the accelerating voltage U=30kv, the beam intensity I=30pA, and The etching depth Z=0.4μm, the magnification is 20000 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com