Rotor of wheel spoke type electric motor and manufacturing method thereof

A manufacturing method and motor technology, which can be used in the manufacture of stator/rotor bodies, etc., can solve problems such as fixing difficulties, and achieve the effects of reducing production costs, reducing manufacturing costs, and increasing torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the content, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

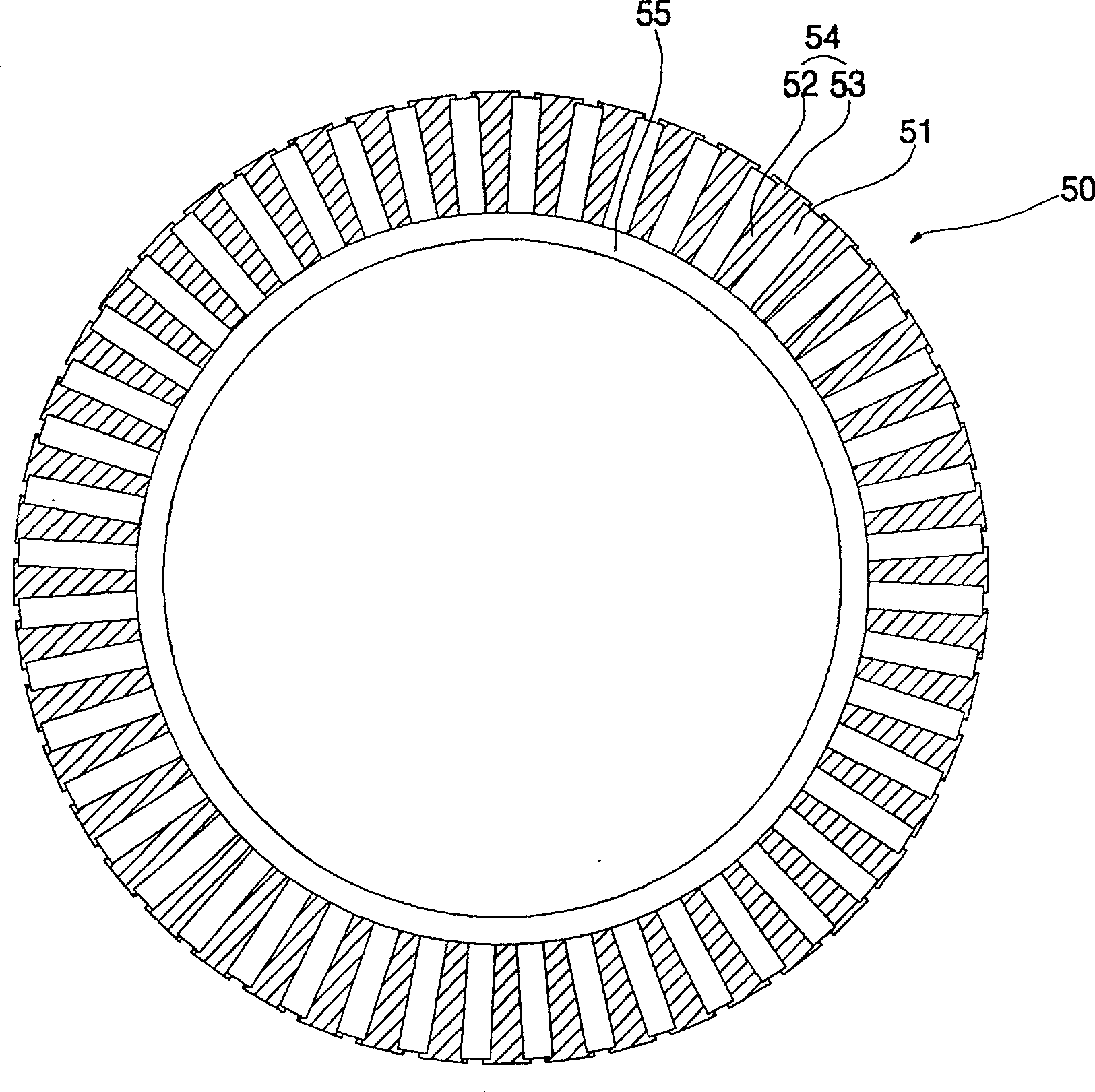

[0042] image 3 It is a cross-sectional view of the rotor of the spoke-type motor of the first embodiment of the present invention.

[0043] The rotor of the spoke-type motor according to the first embodiment of the present invention is composed of a non-electric conductor yoke 55 with a ring shape in the center; and a plurality of rotors arranged radially in the circumferential direction of the yoke 55 and arranged at a certain interval. T-shaped column 54; and a plurality of permanent magnets 51 between the adjacent rotor T-shaped column 54 constituted.

[0044] The rotor T-shaped column 54 includes a rod 52 radiating from the center of the rotor; it is composed of a rod tail 53 flanged in the circumferential direction on the outer end side of the rod 52, and the end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com