Method for preparing aromatic diamine modified nano concavo-convex stick

A technology of nano attapulgite and aromatic diamine, which is applied in the field of surface modification of nano attapulgite, can solve the problems of low reaction efficiency and weak binding force, and achieves high graft reaction efficiency, improved colloidal stability and high thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

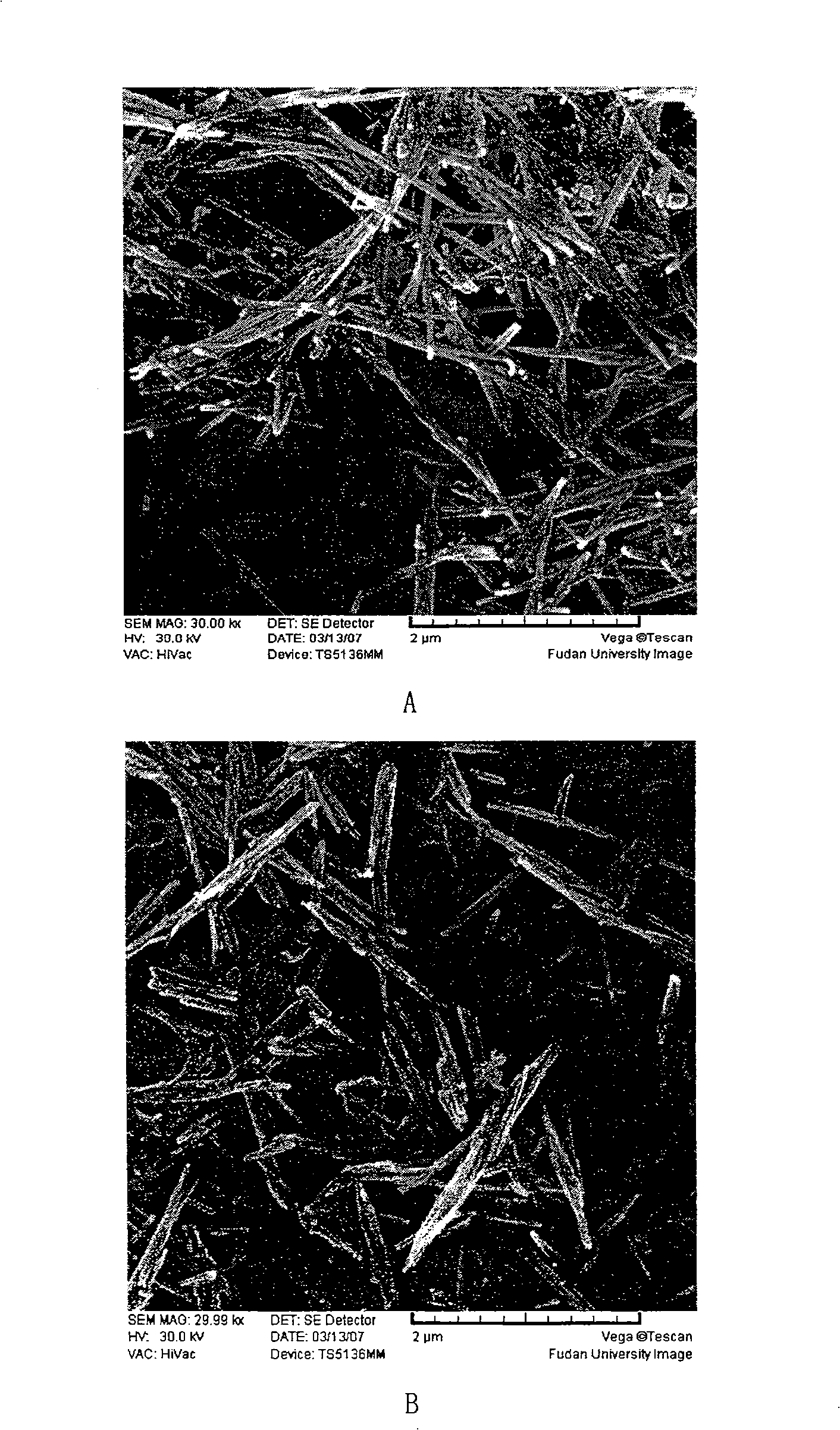

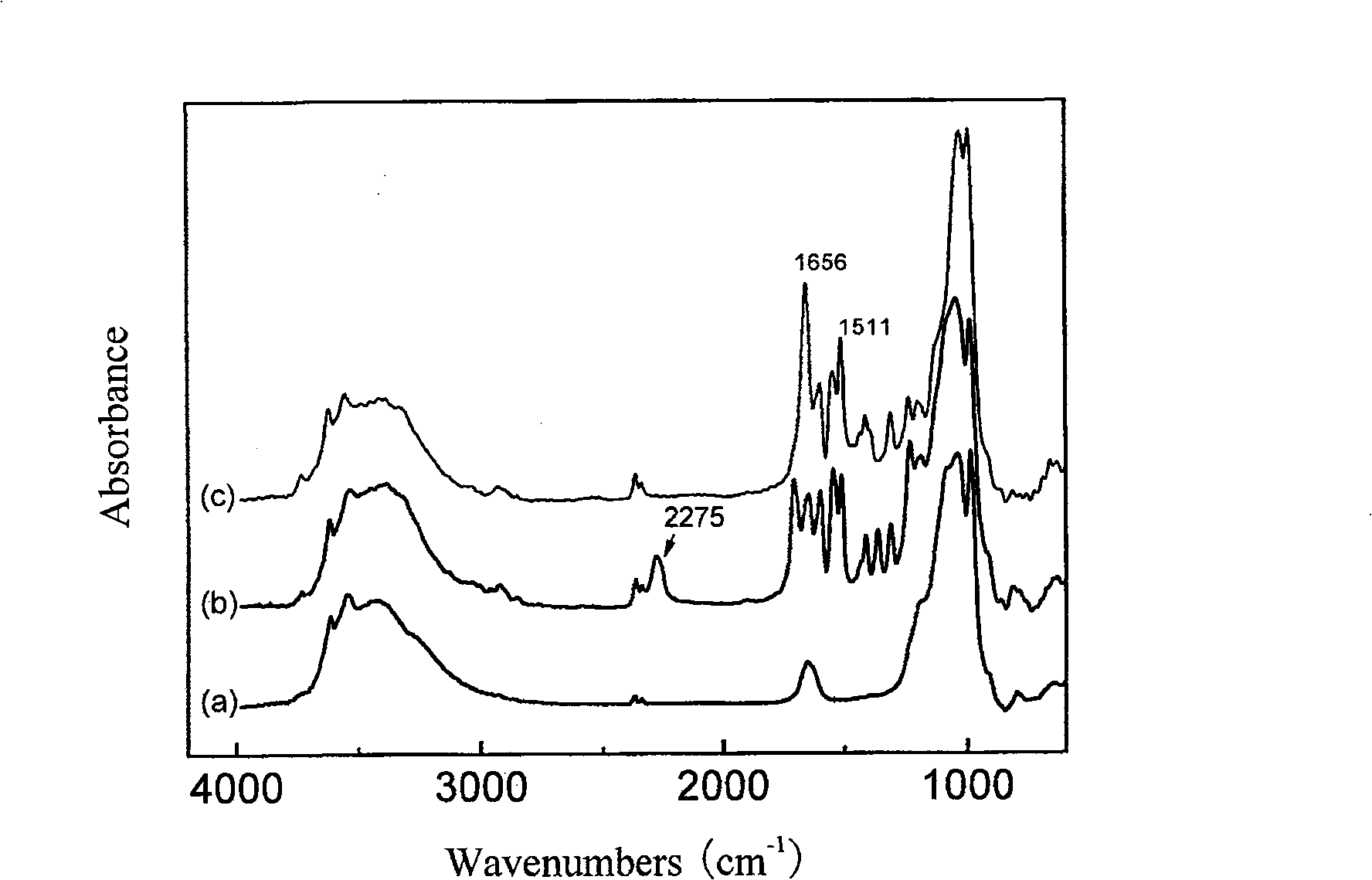

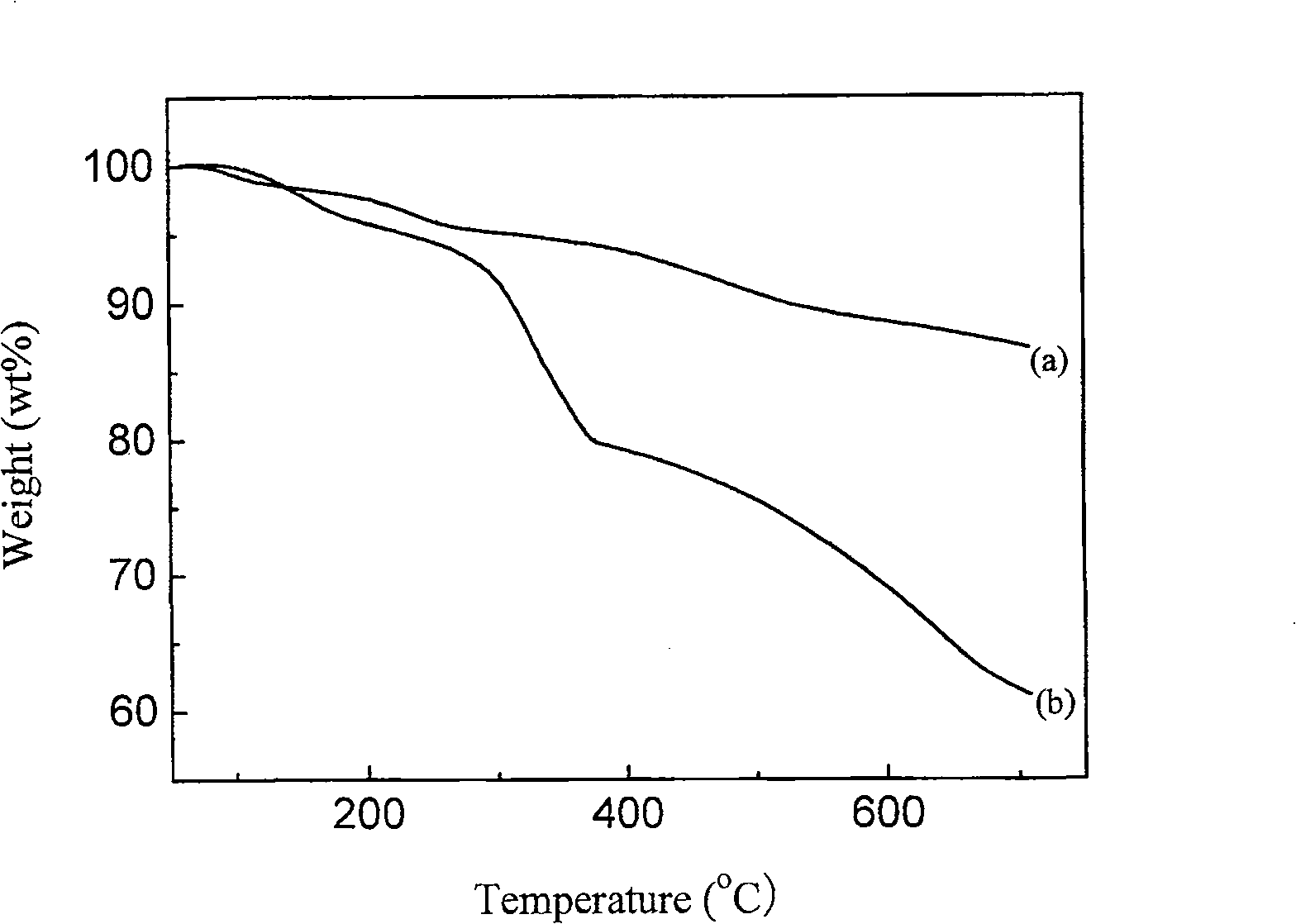

[0026] Embodiment 1: vacuum-dry the attapulgite nanorod at 140-160° C. for more than 12 hours. Disperse 5 g of the purified attapulgite in 75 g of anhydrous dimethylformamide, disperse in a high-shear emulsifier for 50-70 minutes, and ultrasonically disperse for 50-70 minutes to prepare a suspension of attapulgite. Get 2.502g 4,4'-diphenylmethane diisocyanate and dissolve in 20g anhydrous DMF, add gradually in the suspension of above-mentioned attapulgite clay under the condition of blowing nitrogen. The mixture was reacted under reflux under nitrogen protection for 1 h at 80°C. After the reaction was completed, the reaction intermediate was redispersed into 100 g of anhydrous dimethylformamide after centrifugal washing twice with anhydrous dimethylformamide. The suspension was heated to 55°C, and 4 g of 4,4'-diaminodiphenyl ether was added to the suspension. The reaction was stirred overnight under nitrogen protection. After the reaction, the mixed solution was centrifuged...

Embodiment 2

[0027] Example 2: Disperse 10 g of vacuum-dried nano-attapulgite in 70 g of anhydrous dimethylformamide, disperse with a high-shear emulsifier for 1 h, and disperse with ultrasonic for 1 h. Weigh 5.004 g of 4,4'-diphenylmethane Diisocyanate was dissolved in 20 g of anhydrous dimethylformamide, and gradually added to the attapulgite suspension under nitrogen protection. The resulting mixture was reacted at 80° C. under reflux under nitrogen protection for 1 h. After the reaction, anhydrous dimethylformamide was centrifuged and washed twice, and the reaction intermediate was redispersed in 100 g of anhydrous dimethylformamide. The suspension was heated to 60°C, and 16 g of 4,4'-diaminodiphenyl ether was added to the suspension. The reaction was stirred overnight under nitrogen protection. After the reaction, the mixture was centrifuged at 8000r / min, and washed once with anhydrous dimethylformamide, deionized water and acetone in sequence. The obtained aromatic diamine-modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com