Touch control type planar display and producing method thereof

A flat-panel display and manufacturing method technology, applied to static indicators, instruments, electrical digital data processing, etc., can solve the problems of inability to achieve thinness, increase the cost of zero components, increase the overall thickness and weight of the display, and achieve improved wear. Effects of transmittance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

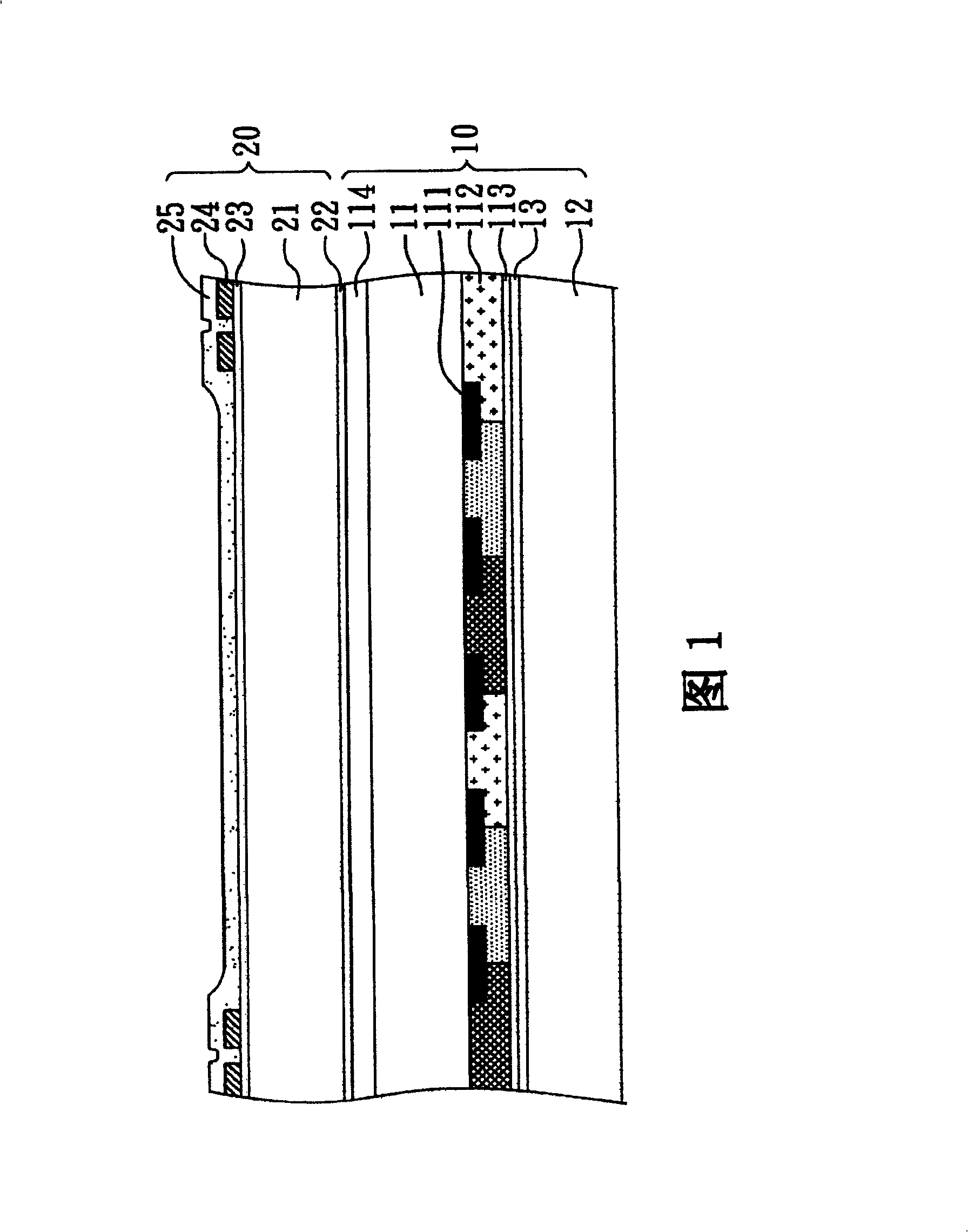

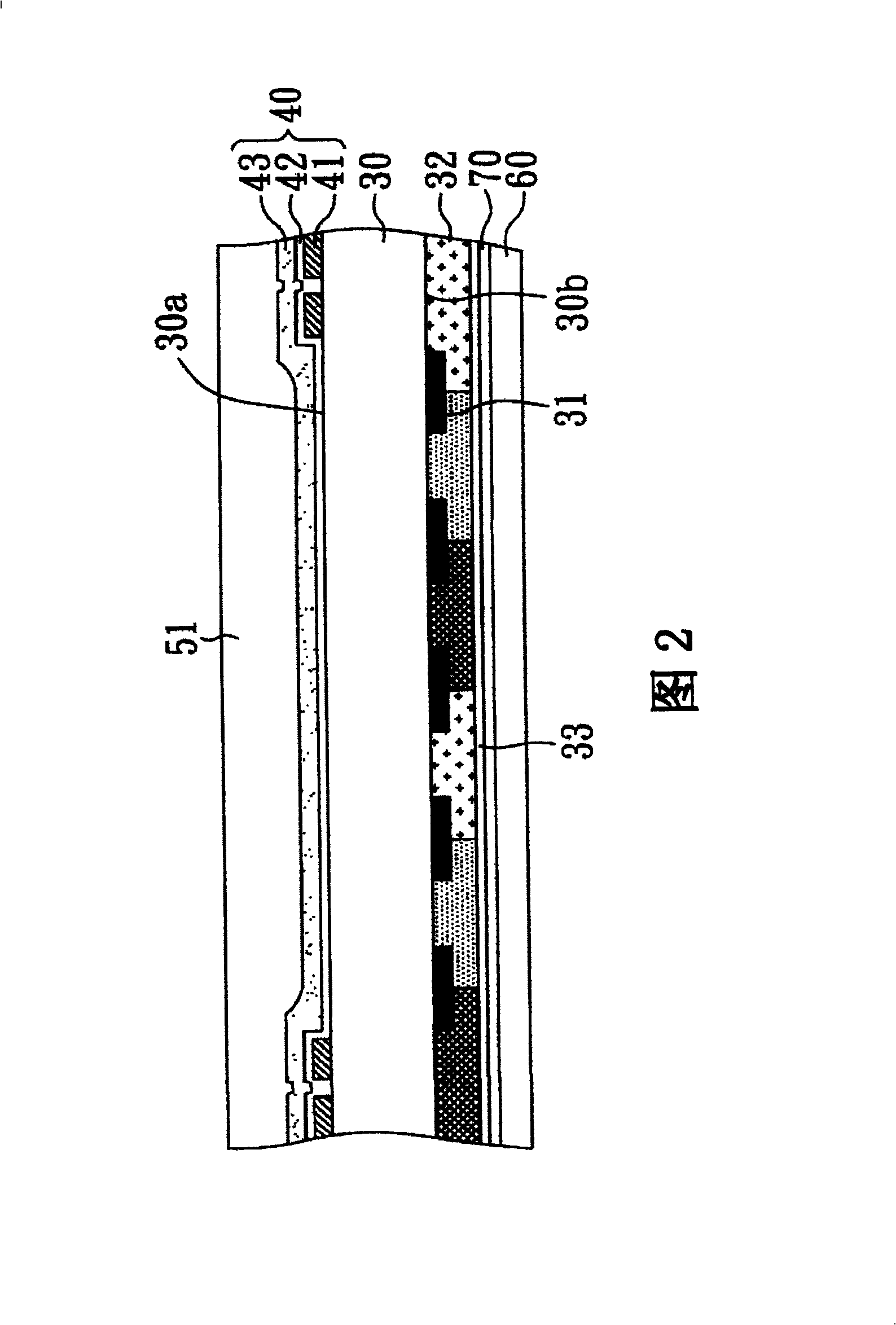

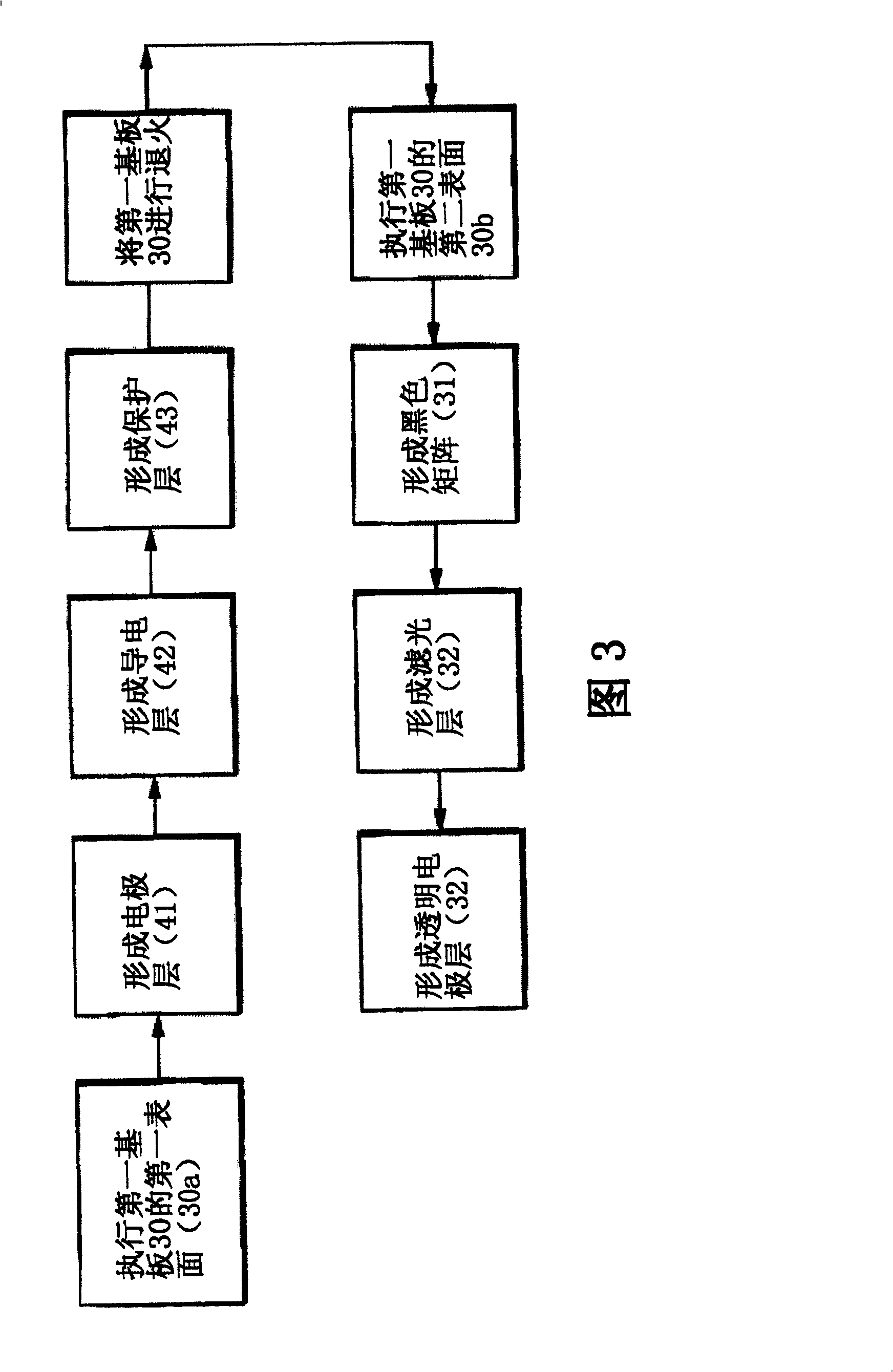

[0055] Please refer to FIG. 2 and FIG. 3 at the same time, wherein FIG. 2 is a cross-sectional view of the touch-sensitive flat panel display of the present invention, and FIG. 3 is a flow chart of the present invention for manufacturing the first substrate. The steps of manufacturing the touch-sensitive flat panel display of this embodiment include: firstly, providing a first substrate 30 having a first surface 30a and a second surface 30b. Here, the material used for the first substrate 30 may be a glass substrate.

[0056] Next, a touch unit 40 is formed on the first surface 30 a of the first substrate 30 , and the step of forming the touch unit 40 is: first forming a patterned electrode layer 41 on the first surface 30 a of the first substrate 30 , wherein , the material used for this electrode layer 41 can be Mo / Al (form aluminum (Al) first, then form molybdenum (Mo)) or can be Mo / Al / Mo (form Mo first, then form Al, and then form Mo) . And, the patterned electrode layer...

Embodiment 2

[0061] This embodiment is substantially the same as Embodiment 1, but the difference is that, please refer to FIG. Use polarizing materials or directly attach polarizers, and can polarize light. Therefore, the protective layer 431 in this embodiment also has the function of the polarizer 51 (as shown in FIG. 2 ) in the first embodiment. Therefore, in this embodiment, the step of additionally attaching the polarizer 51 (as shown in FIG. 2 ) is not performed. All the other steps and structures are the same as in Example 1.

Embodiment 3

[0063] This embodiment is substantially the same as Embodiment 1, but the difference is that please refer to FIG. 7 and FIG. 8 . In this embodiment, when manufacturing the touch unit 40 , a conductive layer 42 is first formed on the first surface of the first substrate 30 30a on. Then, a patterned electrode layer 41 is formed on the surface of the conductive layer 42, wherein the material used for the electrode layer 41 can be Al / Mo (form Mo first, then Al) or Mo / Al / Mo (form first Mo is formed, then Al is formed, and Mo is formed again). The patterned electrode layer 41 is correspondingly formed on the periphery of the first substrate 30 , and its pattern can be the same as that shown in the first embodiment. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com