Heat conduction structure and electronic device

A heat-conducting structure and structural layer technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high density, increasing the weight and thickness of heat dissipation fins or heat sinks, and poor structural strength of polymer composite materials. Improve heat conduction effect and improve heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

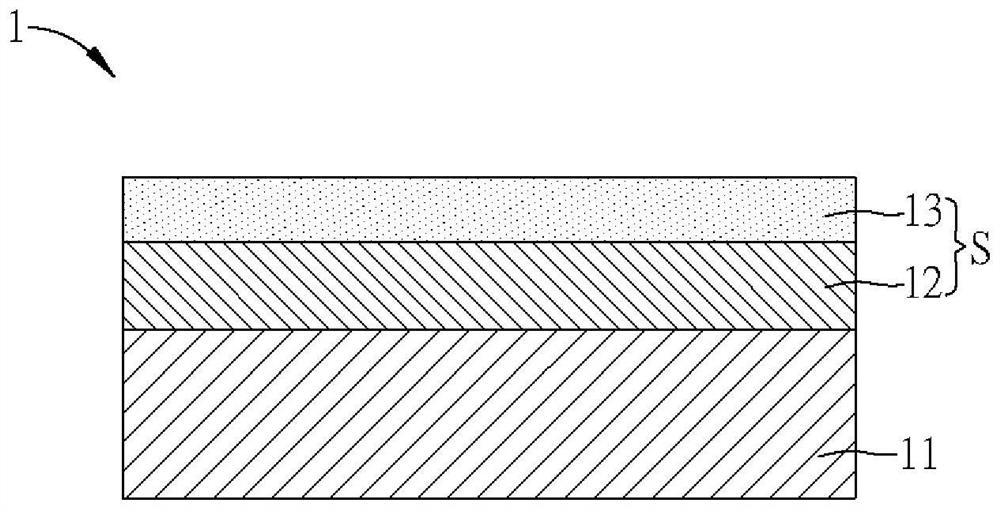

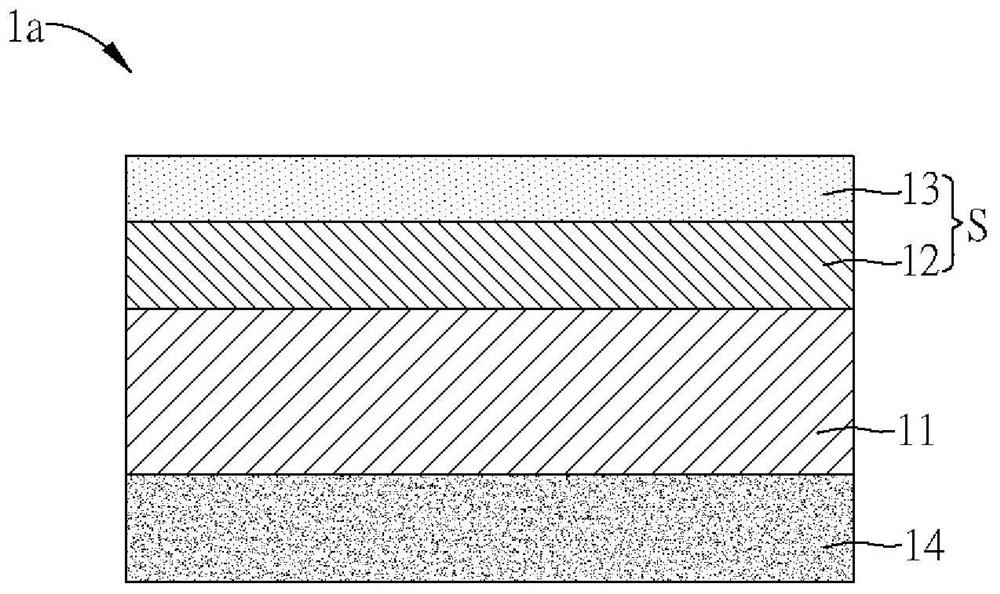

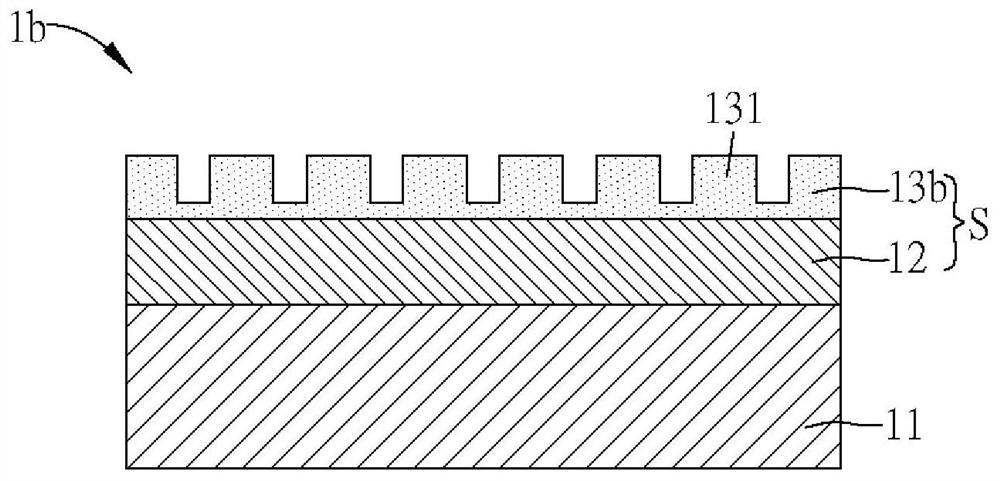

[0027] A thermally conductive structure and an electronic device according to some embodiments of the present invention will be described below with reference to the related drawings, wherein the same components will be described with the same reference numerals. The components in the following embodiments are only used to illustrate their relative relationships, and do not represent the proportions or dimensions of real components.

[0028] When the thermally conductive structure of the present invention is applied to an electronic device, the heat dissipation efficiency of the electronic device can be improved. The heat source of the electronic device can be the battery of the electronic device, a control chip (such as a central control unit (CPU)), a driver chip, a memory (such as but not limited to an SSD solid state drive), a motherboard, a display adapter, a display panel, or a flat light source, or Other components, units, or modules that generate heat are not limited. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com