Method for preparing liquid crystal vertical oriented membrane

A vertical alignment and liquid crystal technology, applied in optics, instruments, nonlinear optics, etc., can solve the few problems such as preparing liquid crystal vertical alignment film, and achieve the effect of simplified process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

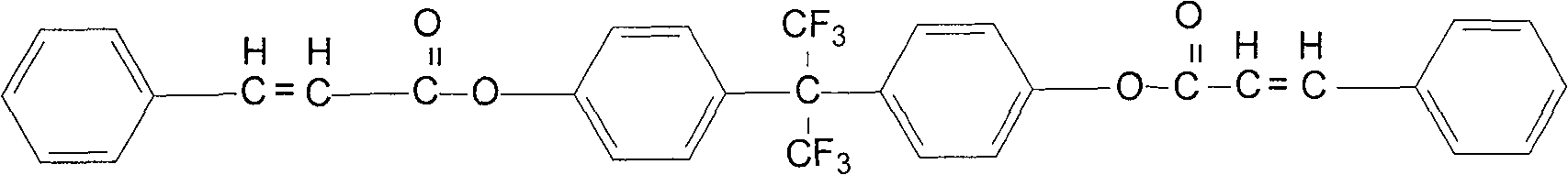

[0027] 1) Synthesis of hexafluorobisphenol A dicinnamate monomer

[0028] Take 3.31 g of hexafluoro-substituted bisphenol A (Aldrich Co., USA) and dissolve it in 40 mL of anhydrous tetrahydrofuran (Tianjin Tiantai Chemical Company, imported sub-packaging), and place it in a 100 mL three-necked bottle. Then take 2.76 mL of triethylamine (Shenyang Dongxing Chemical Factory) and add it directly into the three-necked bottle.

[0029] Take 4.1 g of cinnamoyl chloride (Aldrich Co., USA) and dissolve it in 10 mL of anhydrous tetrahydrofuran, and then place it in a 50 mL dropping funnel.

[0030] Under ice water cooling, the solution of cinnamoyl chloride was slowly added dropwise into the three-necked flask, and at the same time, the automatic stirrer was turned on to stir, and a large amount of white insoluble matter was formed. After the dropwise addition was complete, stirring was continued for 30 minutes.

[0031] The insoluble matter was filtered off to obtain a colorless and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com