Nitrogen-doped nano SiO2/CBN hybrid material and preparation method thereof

A technology of hybrid materials and nitrogen doping, applied in the direction of fibrous fillers, etc., can solve the problems of insufficient reactivity and many functional groups on the surface of lignin, and achieve the effects of improving reactivity, reducing carbon emissions, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

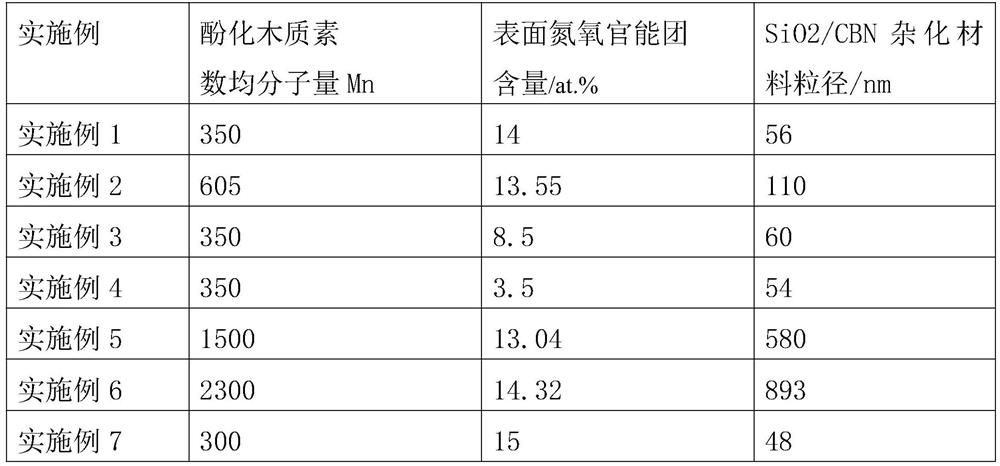

Examples

Embodiment 1

[0048] A preparation method of nitrogen-doped nano-SiO2 / CBN hybrid material, comprising:

[0049] Step S1, separation of hemicellulose and soluble impurities

[0050] Mix the rice husk with a sulfuric acid solution with a mass concentration of 2wt% at a solid-to-liquid ratio of 1kg:8L, heat and reflux for 5h, filter, and wash the filter residue until neutral;

[0051] Step S2, alkali and additives synergistically catalyze the degradation of phenolated lignin and dissolved silica

[0052] The filter residue washed to neutral in step S1 and the mass concentration of 5wt% sodium hydroxide solution are added to the horizontal reactor according to the solid-to-liquid ratio of 1kg:8L, and then the auxiliary agent sodium thiosulfate is added to the system to adjust the concentration 4.5 wt%, stirring evenly, heating at 200°C, hydrothermally degrading lignin at a constant temperature for 3 hours, and filtering to obtain a composite filtrate containing degraded phenolized lignin and s...

Embodiment 2

[0060] The concentration of the additive sodium thiosulfate in step S2 in Example 1 was changed to 1 wt%, and the other conditions were the same as in Example 1 to obtain a SiO2 / CBN hybrid material with 14at.% of nitrogen and oxygen-containing functional groups on the surface.

Embodiment 3

[0062] Change step S5 "under air atmosphere" in embodiment 1 to be under nitrogen and air volume ratio be 50:50 atmosphere, other conditions are identical with embodiment 1, obtain the SiO2 / CBN that surface nitrogen-containing oxygen functional group is 8.5at.% hybrid materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com