Method of producing original position complex sol of tin and titanium

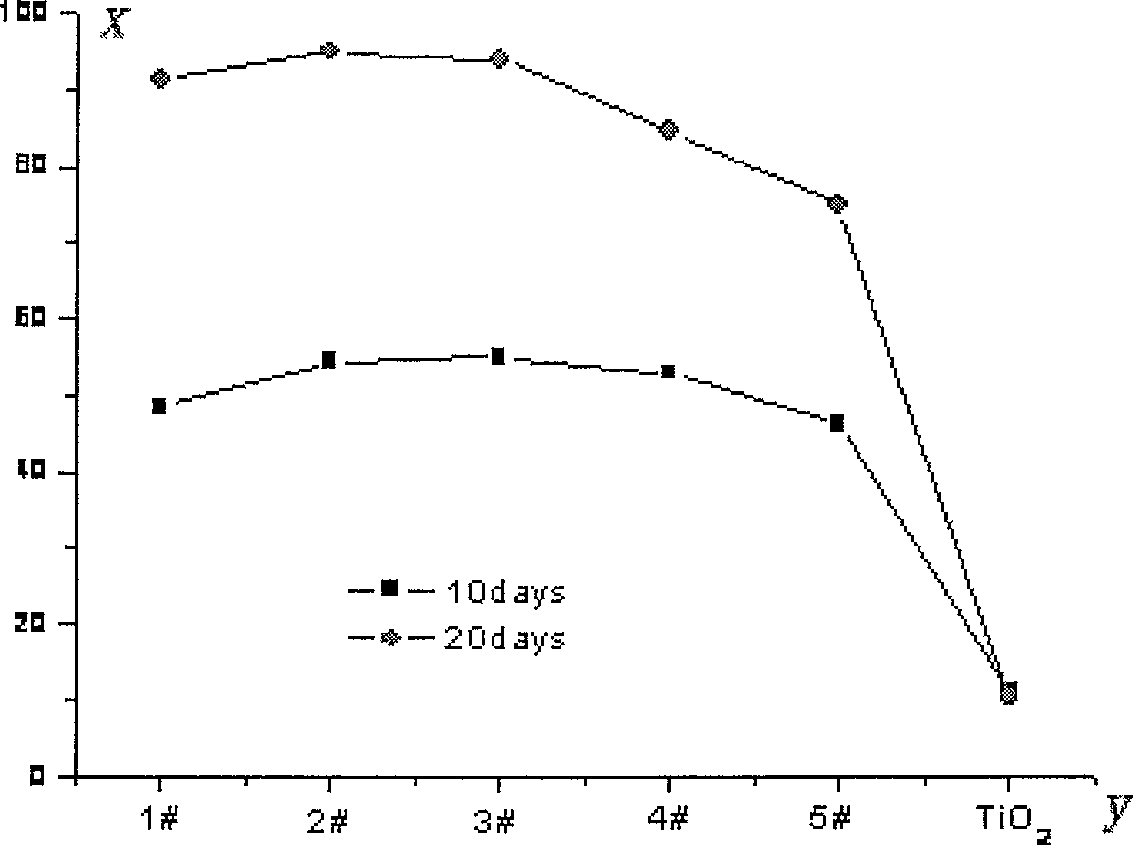

An in-situ composite, tin oxide sol technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as weak photocatalysis ability, avoid high temperature heat treatment, and enhance visible light catalysis. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below through specific examples.

[0017] A preparation method of tin-titanium in-situ composite sol, comprising the following steps:

[0018] (1) Add excess alkali to the tin tetrachloride solution to react to obtain tin hydroxide, filter and wash the obtained tin hydroxide powder, add water peptization with 1 to 500 times the mass of the tin hydroxide powder And standing and aging for 1 hour to 15 days to obtain tin oxide sol;

[0019] (2) Add mineral acid to the tin oxide sol obtained in step (1), so that the pH value of the tin oxide sol is 0.1~5;

[0020] (3) Add at least one of titanium tetrachloride, titanium sulfate or butyl titanate into an alcohol dilution solvent of 1 to 10 times the mass under stirring conditions, stir evenly to obtain a solution, and add the solution dropwise to 1 to 10 times the mass of alcohol dilute solvent. 500 times the mass of the solution obtained in step (2) which was continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com