Iron sodium bismuthate-graphene visible-light-driven Fenton-like composite catalyst used for removing nonyl phenol and preparation method thereof

A technology of sodium bismuthate and graphene, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of efficient degradation and mineralization of refractory active species, Restrict the contact of oxidation active species, the catalytic activity of the catalyst is not high enough, etc., to achieve excellent electron transport performance, enhance the interface reaction ability, and promote the effect of separation and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

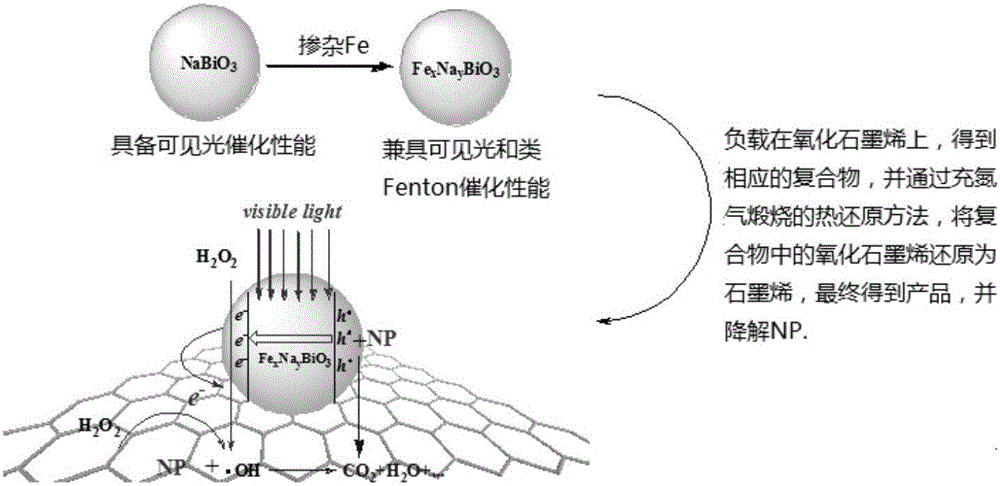

[0033] Embodiment Co-precipitation-thermal reduction method prepares Fe x Na y BiO 3 Complex

[0034] (1) Fe x Na y BiO 3 Preparation of:

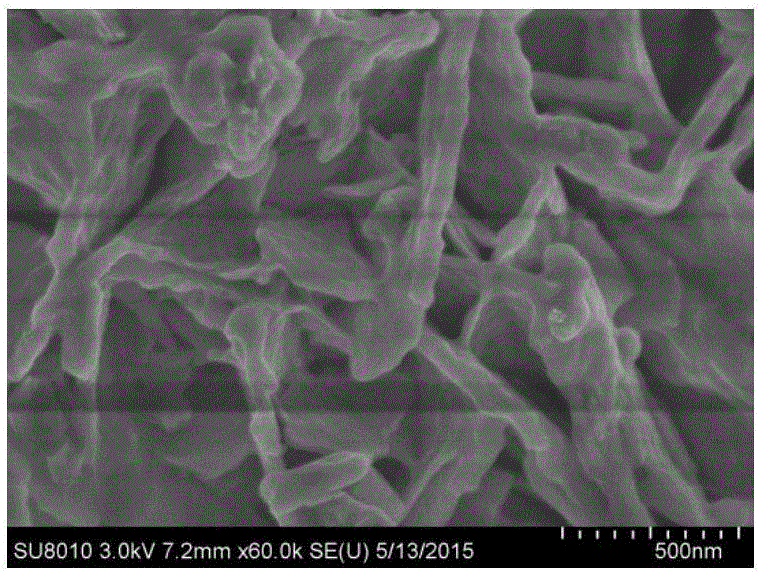

[0035] NaBiO 3 and Fe(NO 3 ) 3 As raw material, Fe was prepared by aqueous phase ion exchange reaction x Na y BiO 3 catalyst. The details are as follows: First, a certain amount of Fe(NO 3 ) 3 Dissolve in deionized water, then add NaBiO 3 , after stirring for a period of time, centrifuge and dry to obtain the product (its scanning electron microscope is as follows: figure 2 shown).

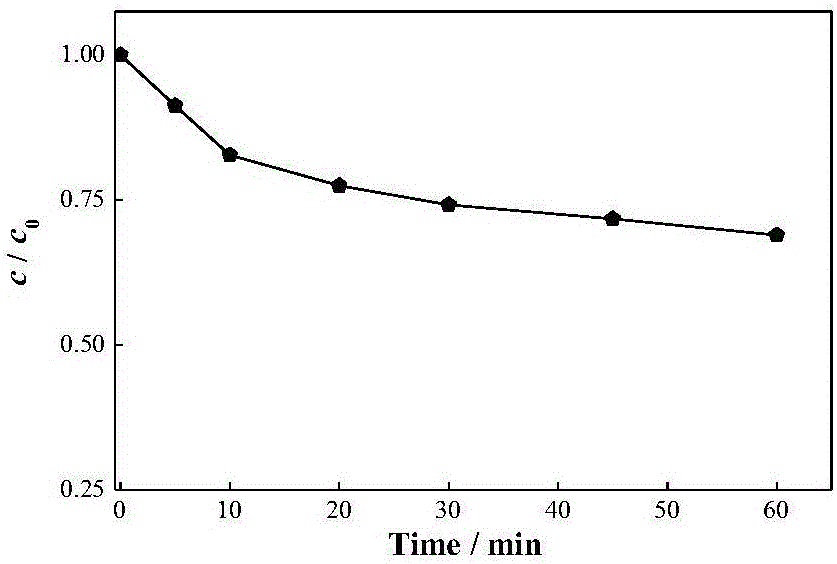

[0036] (2) Fe x Na y BiO 3 Adsorption Evaluation of Nonylphenol by Composite Materials

[0037] Using nonylphenol as the adsorption object, the study of Fe x Na y BiO 3 The adsorption effect on it, the specific adsorption situation is as follows image 3 shown.

[0038] (3) Fe x Na y BiO 3 Degradation Evaluation of Nonylphenol by Composite Materials

[0039] Taking nonylphenol as the degradation object to study Fe x Na y BiO 3 Th...

Embodiment 2

[0040] Embodiment two co-precipitation-thermal reduction method prepares Fe x Na y BiO 3 - Graphene composite

[0041] (1) Fe x Na y BiO 3 Preparation of:

[0042] NaBiO 3 and Fe(NO 3 ) 3 As raw material, Fe was prepared by aqueous phase ion exchange reaction x Na y BiO 3 catalyst. The details are as follows: First, a certain amount of Fe(NO 3 ) 3 Dissolve in deionized water, then add NaBiO 3 , after stirring for a period of time, centrifuge and dry to obtain the product (its scanning electron microscope is as follows: Figure 5 shown).

[0043] (2) Preparation of graphene oxide (GO)

[0044] First, using graphite as raw material, the Hummers method ( J. Am. Chem. Soc. 1958, 80: 1339) to prepare graphene oxide (scanning electron microscope such as Image 6 shown).

[0045] (3) Fe x Na y BiO 3 - Preparation of graphene composites

[0046] Fe x Na y BiO 3 -Composite preparation of graphene oxide: compound method uses liquid phase deposition method to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com