Stripper in use for large sized hydraulic machine

A technology of hydraulic press and demoulding machine, which is applied in the field of hydraulic presses, and can solve the problems that the overall structure of the hydraulic press is huge and cannot reach the return force of the cylinder piston of a large hydraulic machine, and achieve the effect of compact structure, large demoulding force, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

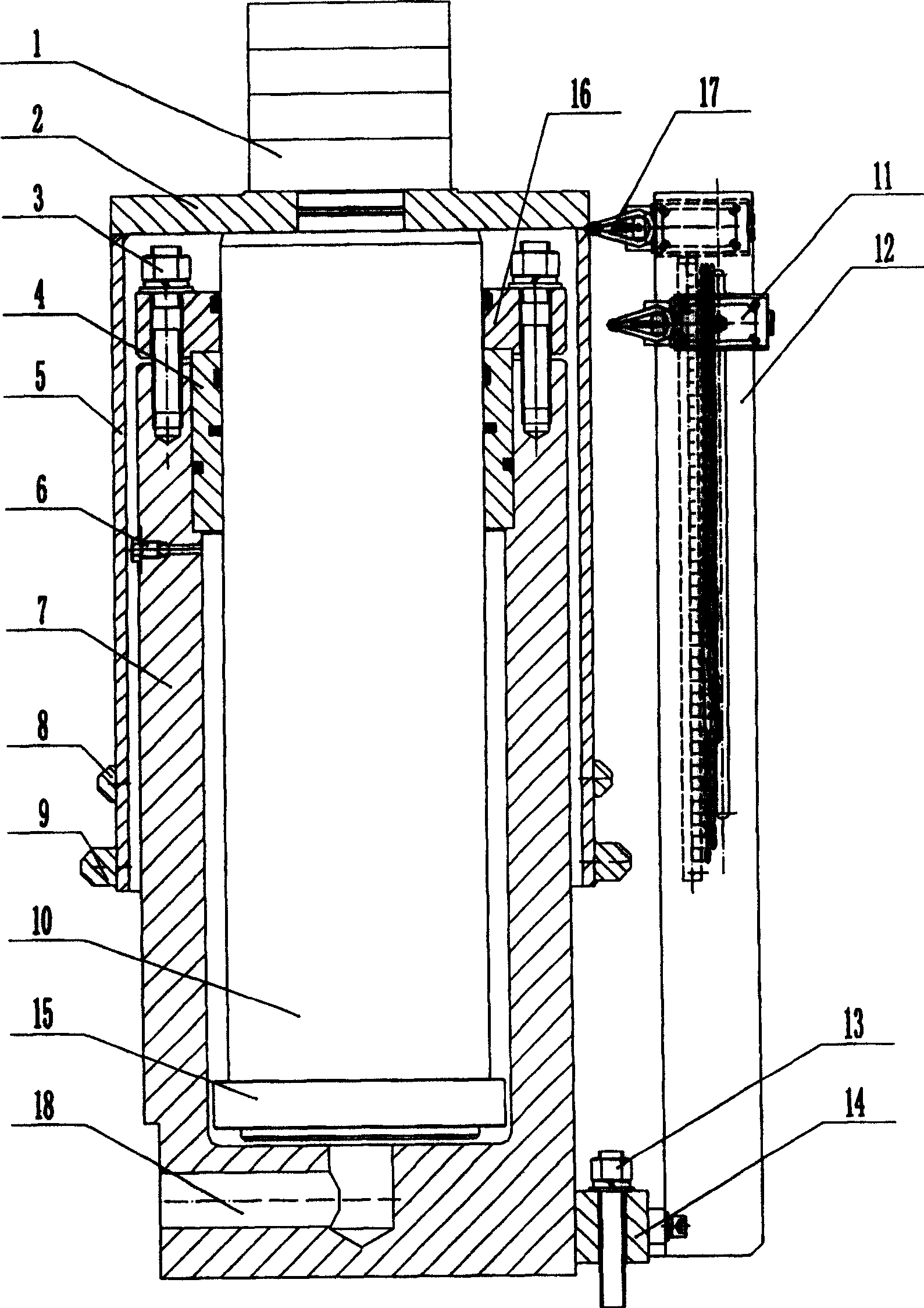

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] Such as figure 1 As shown, the demoulding machine for a large hydraulic press of the present invention includes a cylinder 7 and a plunger rod 10 that is located in the cylinder 7 and can move up and down along its inner wall. The upper end of the cylinder 7 is an open structure And be covered with top cover 16 by screw 3, this top cover 16 center is formed with the through hole corresponding with the rod body diameter of plunger rod 10, and the lower end of cylinder body 7 is formed with the oil port 18 of its internal oil inlet. The bottom end of the plunger rod 10 is formed with a boss 15 whose diameter is larger than the rod body, and the upper end of the plunger rod 10 passes through the top cover 16 . A cylinder m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com