Full automatic technique of graded deferrization, and equipment

A fully automatic and advanced technology, applied in the field of magnetic separation, can solve the problems of not realizing the iron removal effect and high iron removal efficiency, and achieve the effect of avoiding the weakening of adsorption capacity, improving work efficiency and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

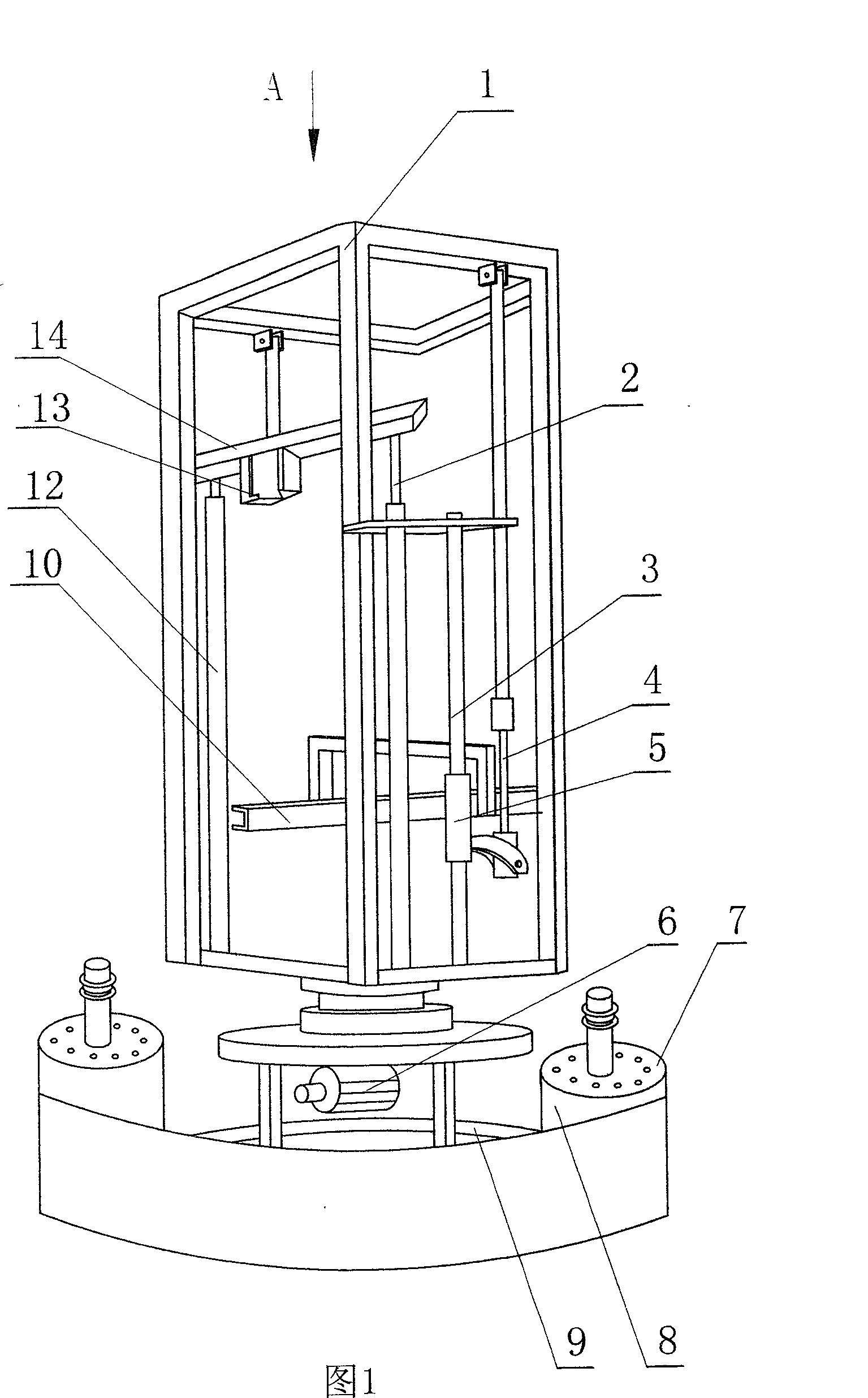

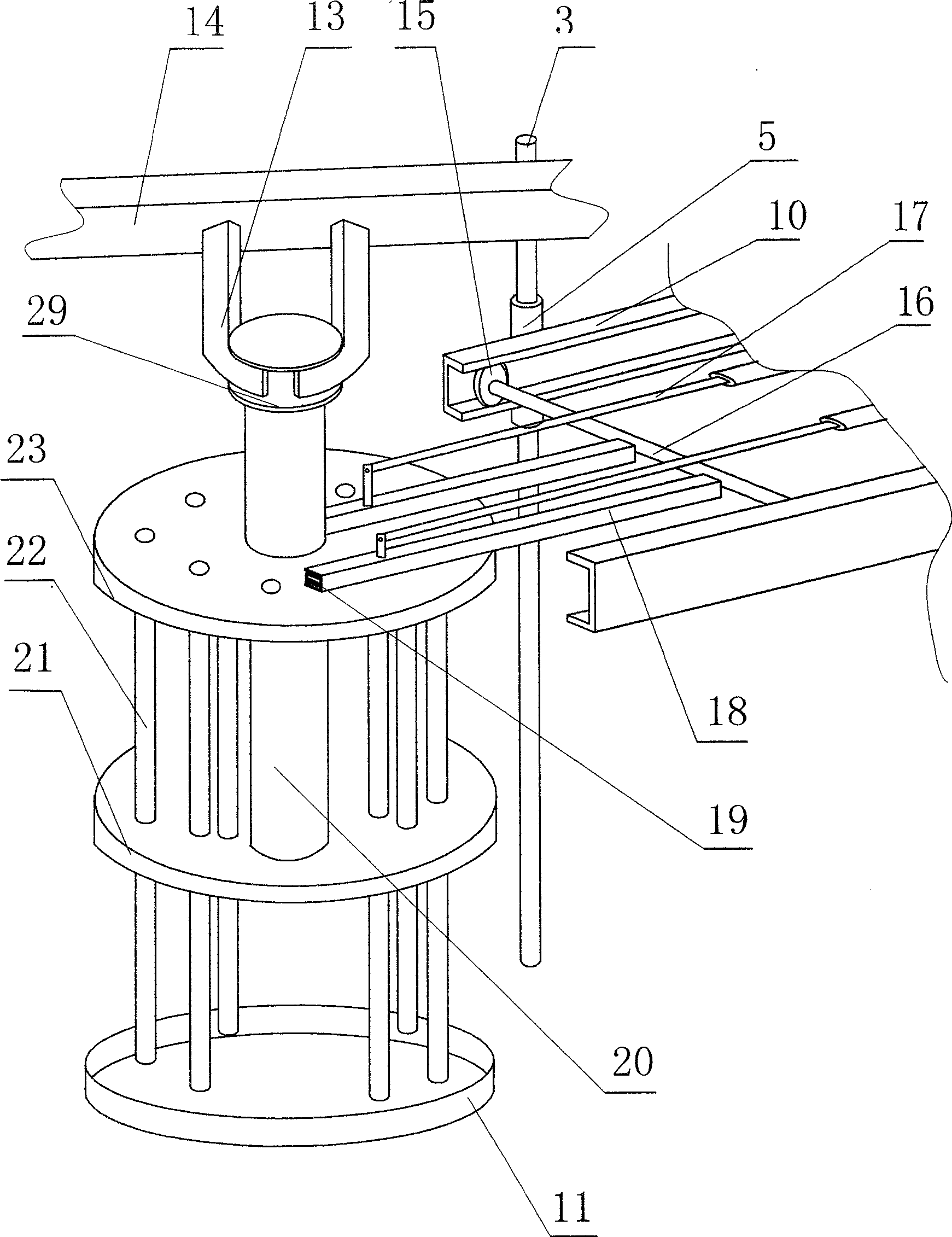

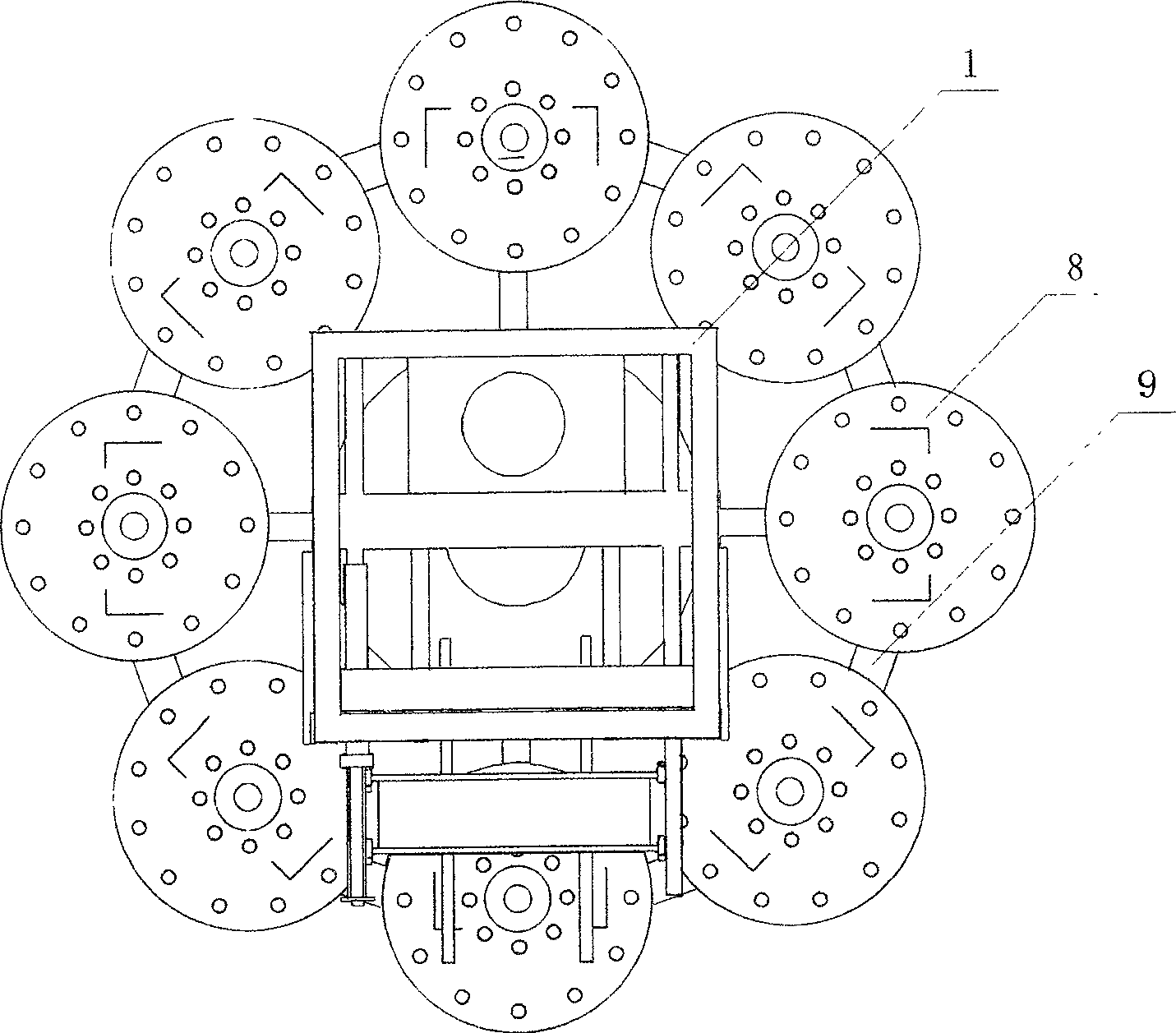

[0032] Figure 1, image 3 As shown, a plurality of slurry tanks 8 are placed on the bottom frame 9 in a ring shape, and each slurry tank is connected. As can be seen from Fig. 1, the reducer 6 is fixedly connected to the bottom frame 9, and the power output shaft of the reducer 6 is connected with the frame 1, and the frame 1 can slowly rotate when the reducer is working. A guide column 3 is erected on the frame 1, and a sliding sleeve 5 is set on the guide column 3, and the sliding sleeve 5 can slide up and down along the guide column 3. The sliding sleeve 5 is connected with the hydraulic column 4 of the first vertical oil cylinder, and when the hydraulic column of the first vertical oil cylinder moves up and down, the sliding sleeve 5 is driven to move up and down; the sliding sleeve 5 is fixed with a guide rail 10 . figure 2 Among them, there is a coupling shaft 16 between the two guide rails 10, and rollers 15 are installed at the two ends of the coupling shaft 16, and t...

Embodiment 2

[0037] As shown in FIG. 6 , the feature of this embodiment is that the slurry tanks 31 are arranged in a linear determinant, and guide rails 29 are arranged on both sides of the slurry tank, and sliding frames 40 are installed on the guide rails 29 . The carriage 40 moves along the guide rail 29 under the action of the driving mechanism. A guide column 36 is set in the slide frame 40, and a sliding sleeve 38 is set on the guide column 36, and the sliding sleeve is connected with a boom 41, and the sliding sleeve 38 is connected with the hydraulic column of the vertical oil cylinder. Fix the slot 37 on the top plate 35 of the magnetic suction roller 30, the boom 41 can just stretch into the slot 37, the fastener is fixed on the scraper 32 of the magnetic suction roller 30, the hydraulic column 33 of the horizontal oil cylinder is connected to the pulling bracket 34, and the pulling bracket 34 ends can be fastened on the scraper fastener.

[0038] The working process of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com