Bent axle push-stopping surface polishing device

A technology of polishing device and thrust surface, applied in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve the problems of complex structure, low work efficiency, high price, etc., achieve high processing finish, reduce labor intensity, and produce high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

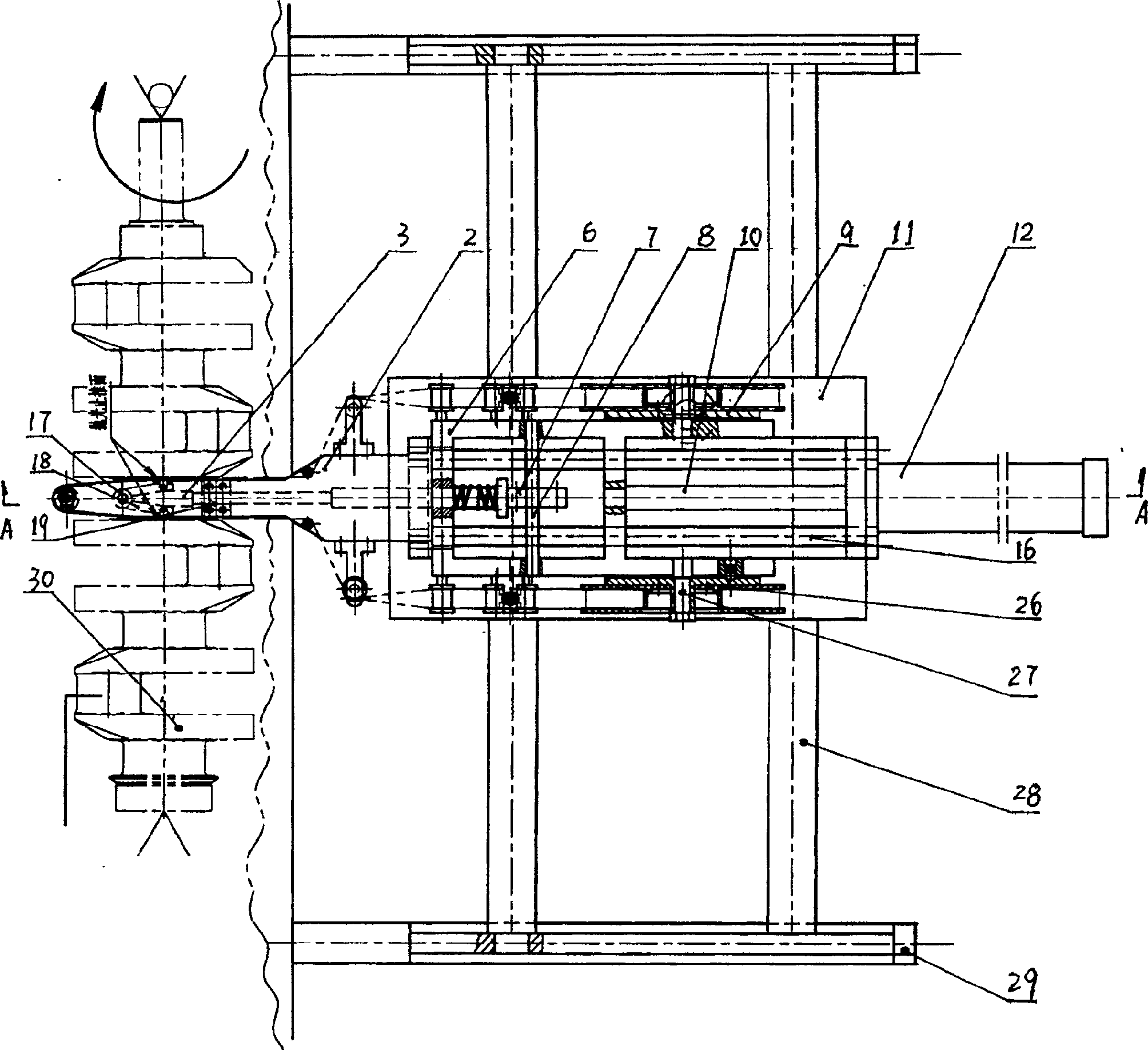

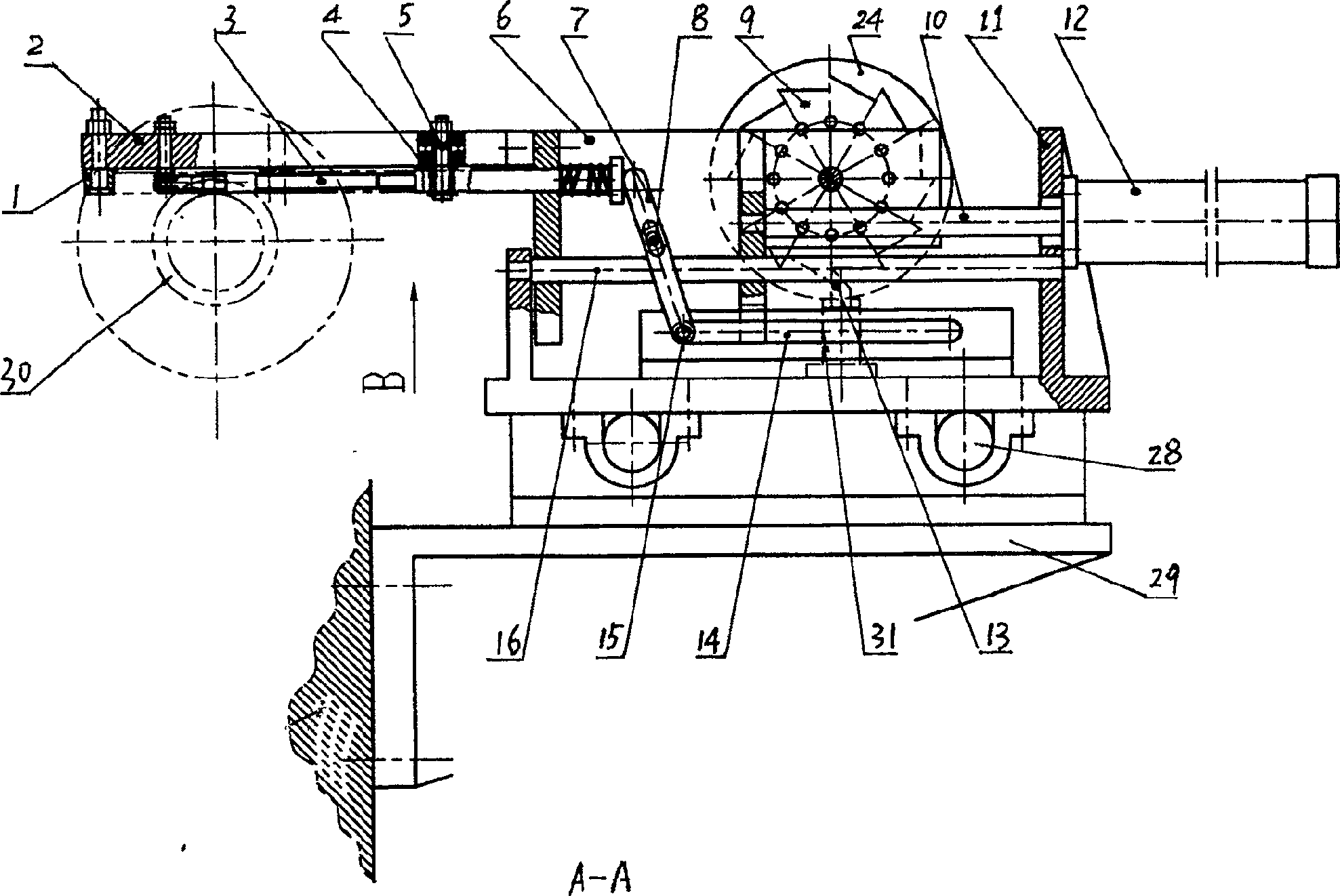

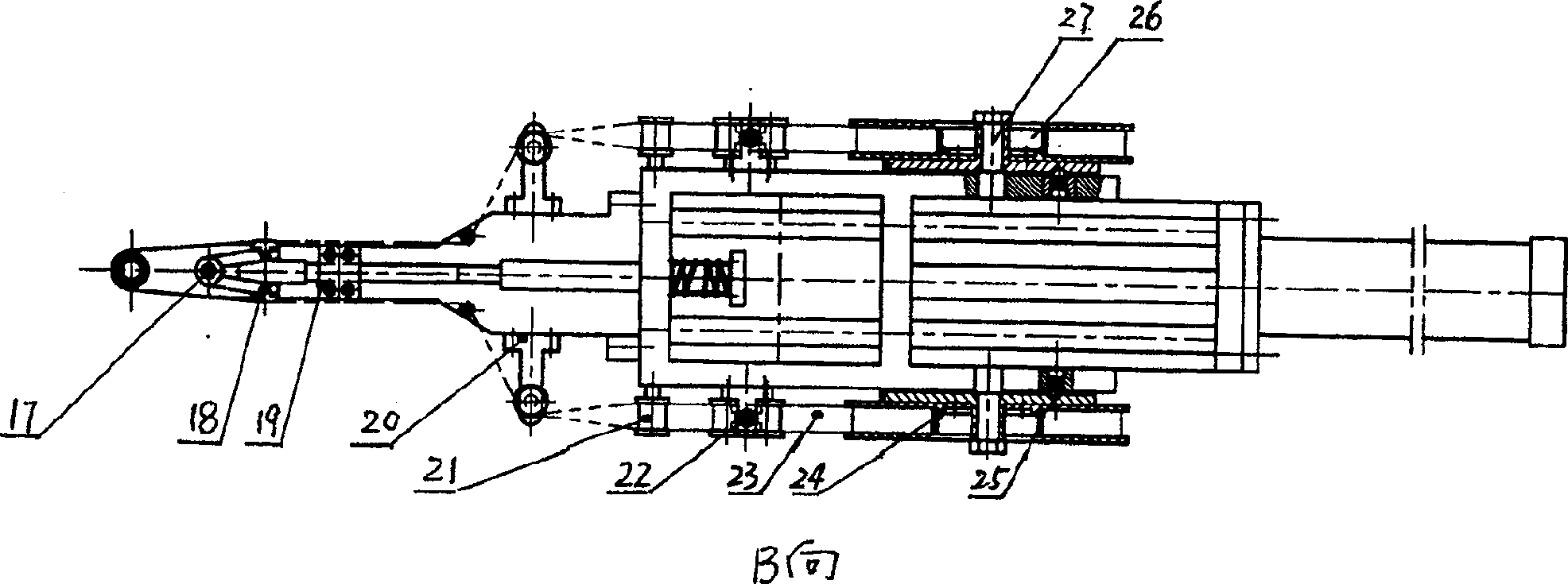

[0019] The invention relates to a crankshaft thrust surface polishing device, which mainly includes a longitudinal movement mechanism, a transverse feed tension mechanism, and a winding mechanism.

[0020] From figure 1 , figure 2 It can be seen from the figure that the longitudinal movement mechanism of the present invention mainly includes a base 11, a guide column 28, a bracket 29, etc., the guide column 28 is installed on the bracket 29 connected with the machine bed, and the whole device base 11 is installed on the guide column 28 , and can move horizontally along the longitudinal direction of the guide column 28.

[0021] From figure 1 , figure 2 It can also be seen from the figure that the lateral feed tensioning mechanism of the present invention mainly includes a cylinder 12, a piston rod 10, a sliding support 6, a supporting plate 2, a pressure rod 7, a conical expansion rod 3, an expansion block 18, a guide rod 16, etc. . Wherein the cylinder 12 is installed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap