Method for preparing nano silicone based luminescence composite film

A composite film and nano-silicon technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as poor compatibility and low luminous efficiency, and achieve simple production equipment, high pollution-free, and photon reduction. The effect of reabsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

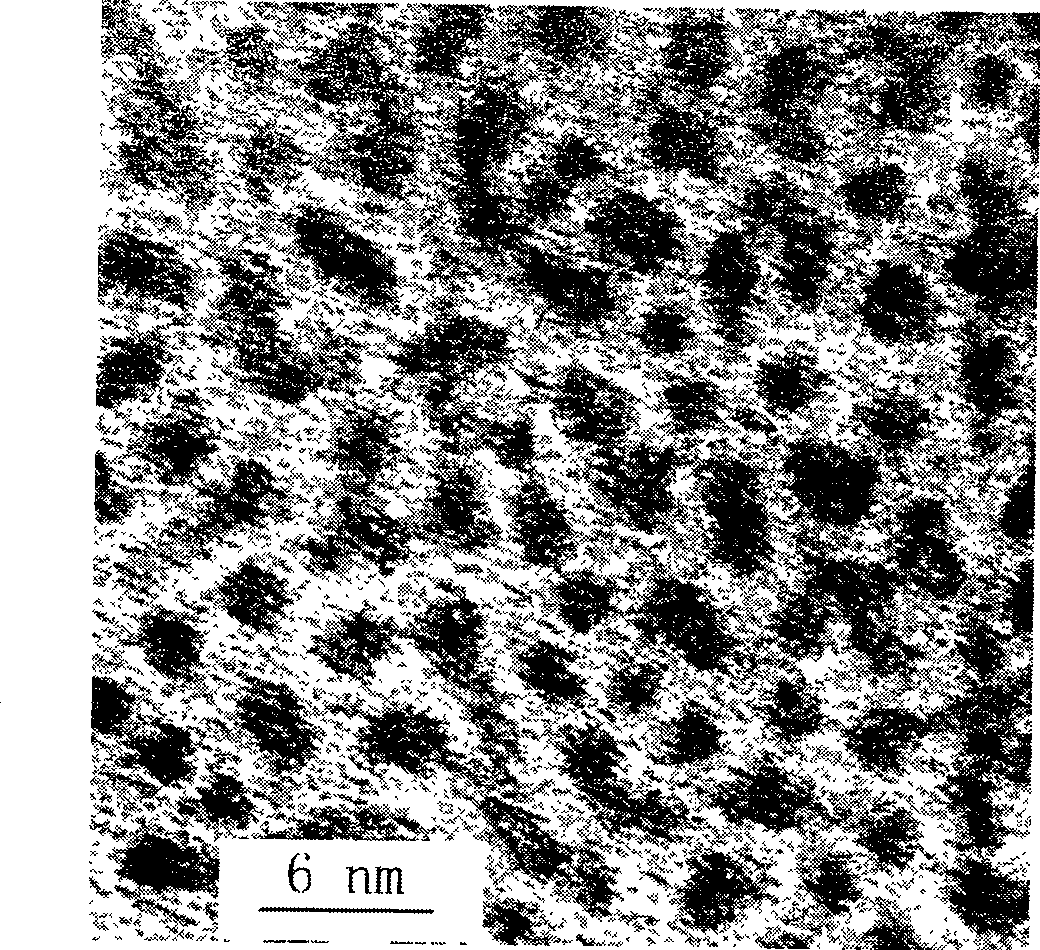

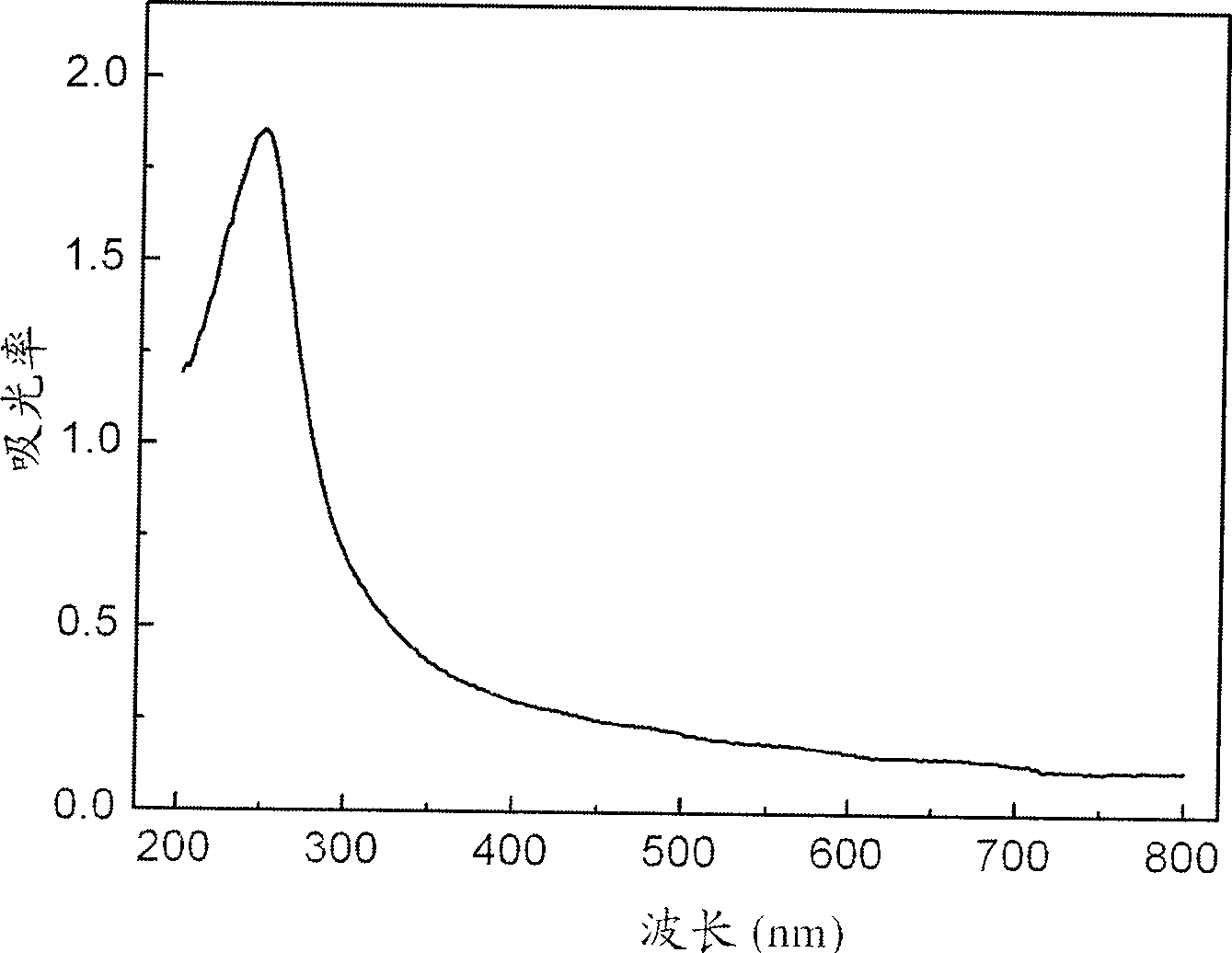

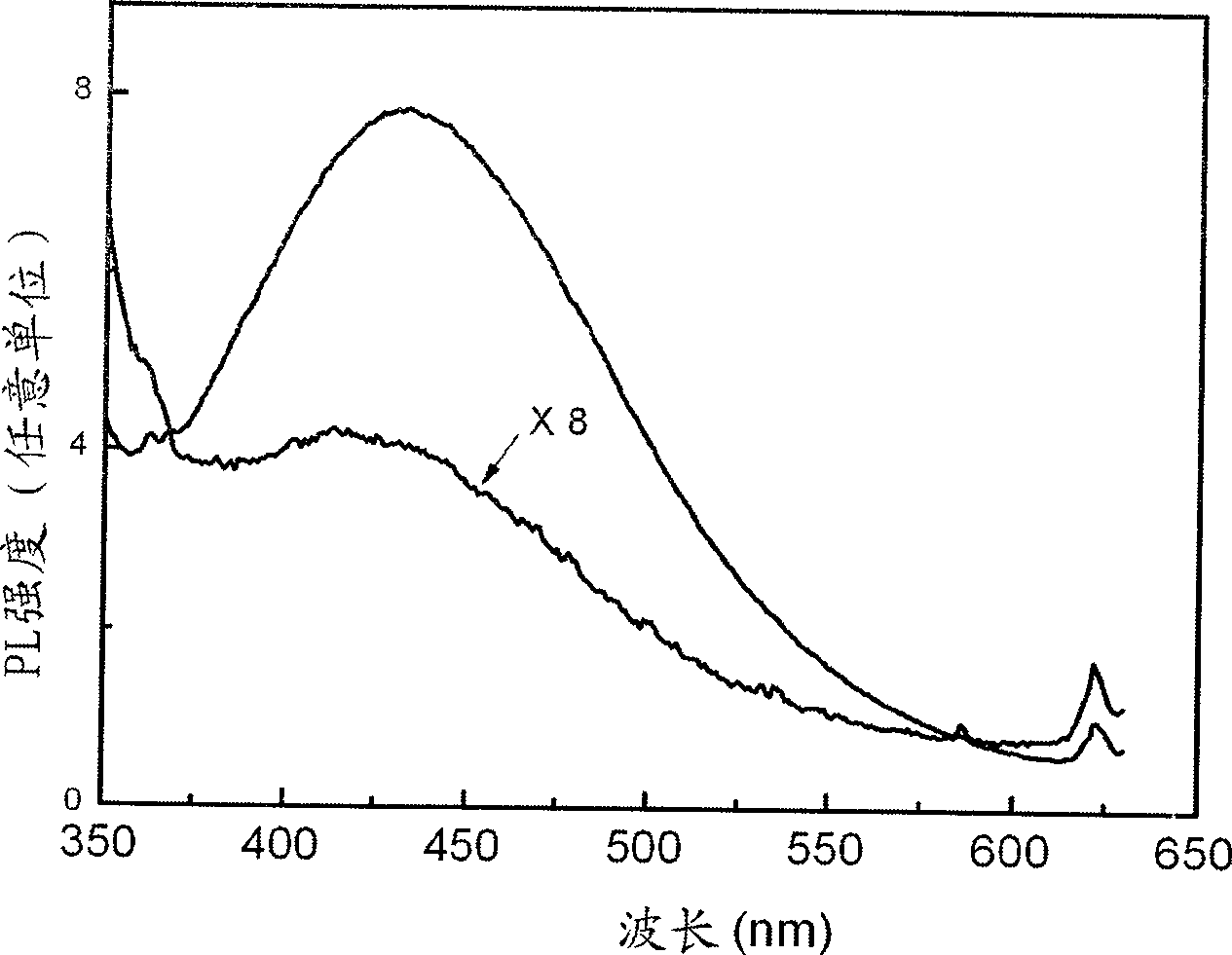

[0025] Example 1 Preparation of nano-SiO 1.8 Luminescent Composite Film

[0026] 1. Sonicate the monocrystalline silicon wafer with acetone, alcohol, and deionized in turn for 10 minutes; boil the monocrystalline silicon wafer with deionized water for 10 minutes under boiling conditions; dry the residual moisture on the monocrystalline silicon wafer, and then use The mask fixes the monocrystalline silicon wafer into the groove on the lower surface of the upper plate of the capacitor plate to ensure that the single crystal silicon wafer does not loosen: put the capacitor plate into capacitively coupled plasma enhanced chemical vapor deposition (PECVD) The vacuum chamber of the system;

[0027] 2. The upper plate of the capacitor plate is grounded, the purity of silane, hydrogen and nitrous oxide is 99.99%, and the silane (SiH 4 ) (diluted in hydrogen at a volume ratio of 2%), hydrogen and nitrous oxide (N 2 O) according to SiH 4 :H 2 :N 2 The flow ratio of O=15:10:8 is fu...

Embodiment 2

[0031] Example 2 Preparation of nano-SiO 1.5 Luminescent Composite Film

[0032] 1. Sonicate the monocrystalline silicon wafer with acetone, alcohol, and deionized in turn for 10 minutes; boil the monocrystalline silicon wafer with deionized water for 2 minutes under boiling conditions; dry the residual moisture on the monocrystalline silicon wafer, and then use The mask sheet fixes the monocrystalline silicon wafer to the groove on the lower surface of the upper plate of the capacitor plate to ensure that the single crystal silicon wafer does not loosen; put the capacitor plate into capacitively coupled plasma enhanced chemical vapor deposition (PECVD) The vacuum chamber of the system;

[0033] 2. The upper plate of the capacitor plate is grounded, the purity of silane, hydrogen and oxygen is 99.99%, and the silane (SiH 4 ) (diluted in hydrogen at a volume ratio of 2%), hydrogen and oxygen (O 2 ) according to SiH 4 :H 2 :O 2 = The flow ratio of 13:10:1 is fully mixed in...

Embodiment 3

[0037] Example 3 Preparation of nano-SiN 1.1 Luminescent Composite Film

[0038] 1. Sonicate the quartz glass with acetone, alcohol, and deionized in turn for 10 minutes; boil the quartz glass with deionized water for 20 minutes under boiling conditions; dry the residual moisture on the quartz glass, and then use a mask Be fixed in the groove of the lower surface of the upper plate of the capacitor plate to ensure that the quartz glass is not loose; put the capacitor plate into the vacuum chamber of the capacitively coupled plasma enhanced chemical vapor deposition (PECVD) system;

[0039] 2. Ground the upper plate of the capacitor plate, the purity of silane, hydrogen and nitrogen is 99.99%, silane (SiH 4 ) (diluted in hydrogen at a volume ratio of 2%), hydrogen and nitrogen (N 2 ) according to the treated SiH 4 :H 2 :N 2 = The flow ratio of 13:10:1 is fully mixed in the mixing chamber, and the mixed gas enters between the two pole plates at a uniform speed from the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com