Biomass particle mold

A technology of biomass particles and molds, which is applied in the direction of biofuel, raw material extrusion granulation, waste fuel, etc., can solve the problems of unstable performance, energy saving and efficiency improvement, etc., to enhance wear resistance and improve single-hour Yield, the effect of reducing feed resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

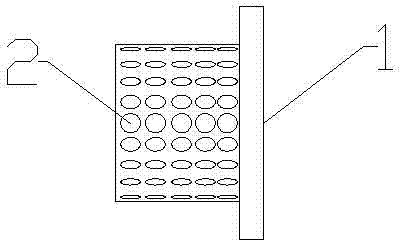

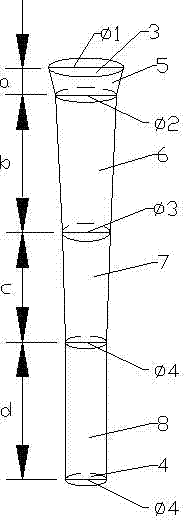

[0017] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this kind of biomass particle mold includes a mold body 1. There are many feed holes 2 on the mold body 1. The mold body 1 is made of steel with a carbon content of 1.4% after carburizing treatment. The feed holes 2 It is composed of the first conical hole 5, the second conical hole 6, the third conical hole 7 and the straight cylindrical hole 8 connected in sequence from the inlet 3 to the outlet 4. The first conical hole 5, the second conical hole 6, and the third conical hole The heights of the hole 7 and the straight hole 8 are a: 3.8-4.2mm, b: 15.8-16.2mm, c: 15.8-16.2mm and d: 19.8-20.2mm, and the preferred schemes are a: 4mm, b: 16mm, c: 16mm and d: 20mm, the diameter of the upper hole of the first conical hole 5 is ф1: 10.8~11.5mm, preferably 11mm, the diameter of the lower hole is ф2: 8.8~9.2mm, preferably 9mm, the diameter of the second conical ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com