Two-degree-of-freedom plane parallel robot mechanism

A degree of freedom, robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as difficulty in eliminating the influence of the positioning accuracy of the rotating bearing, limiting the acceleration of the end effector, etc., achieving low inertia, simple structure, and high drive. Effects of stiffness and thrust-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

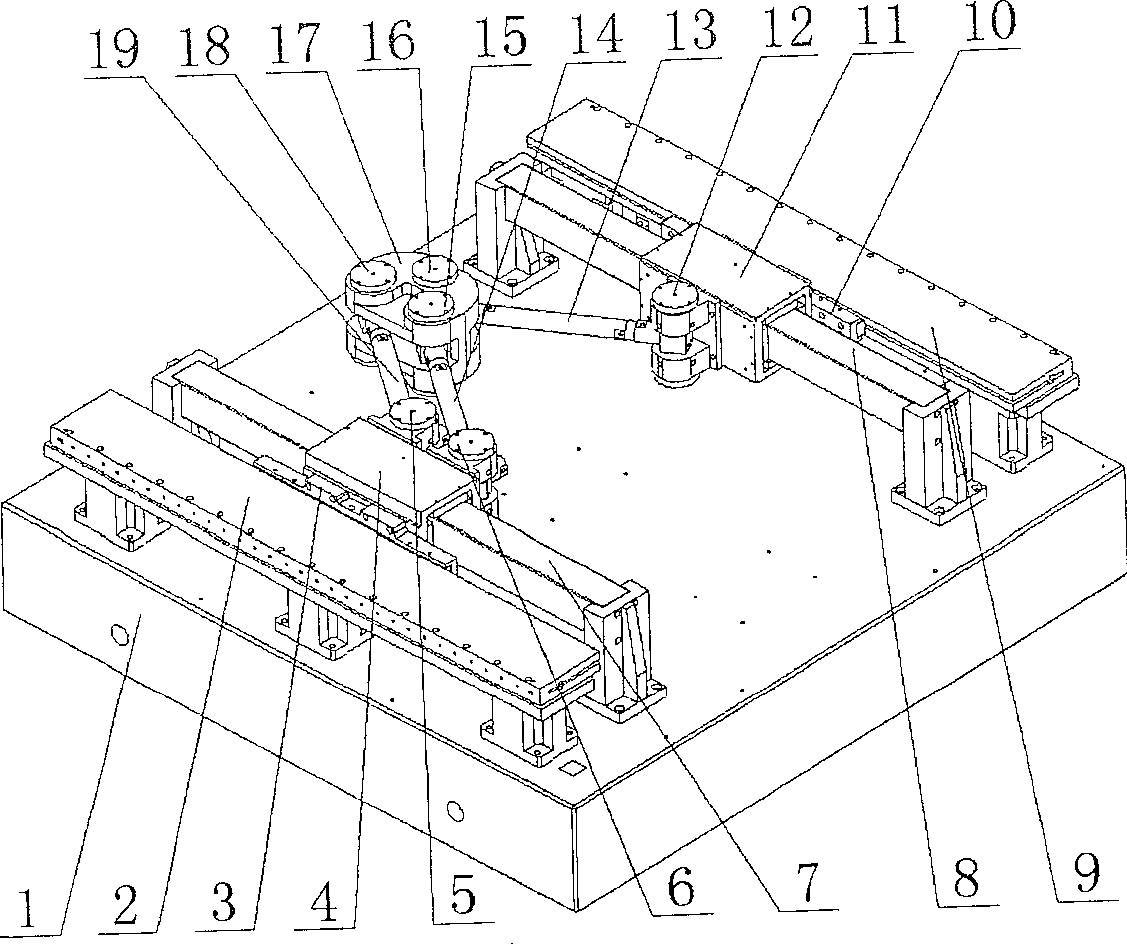

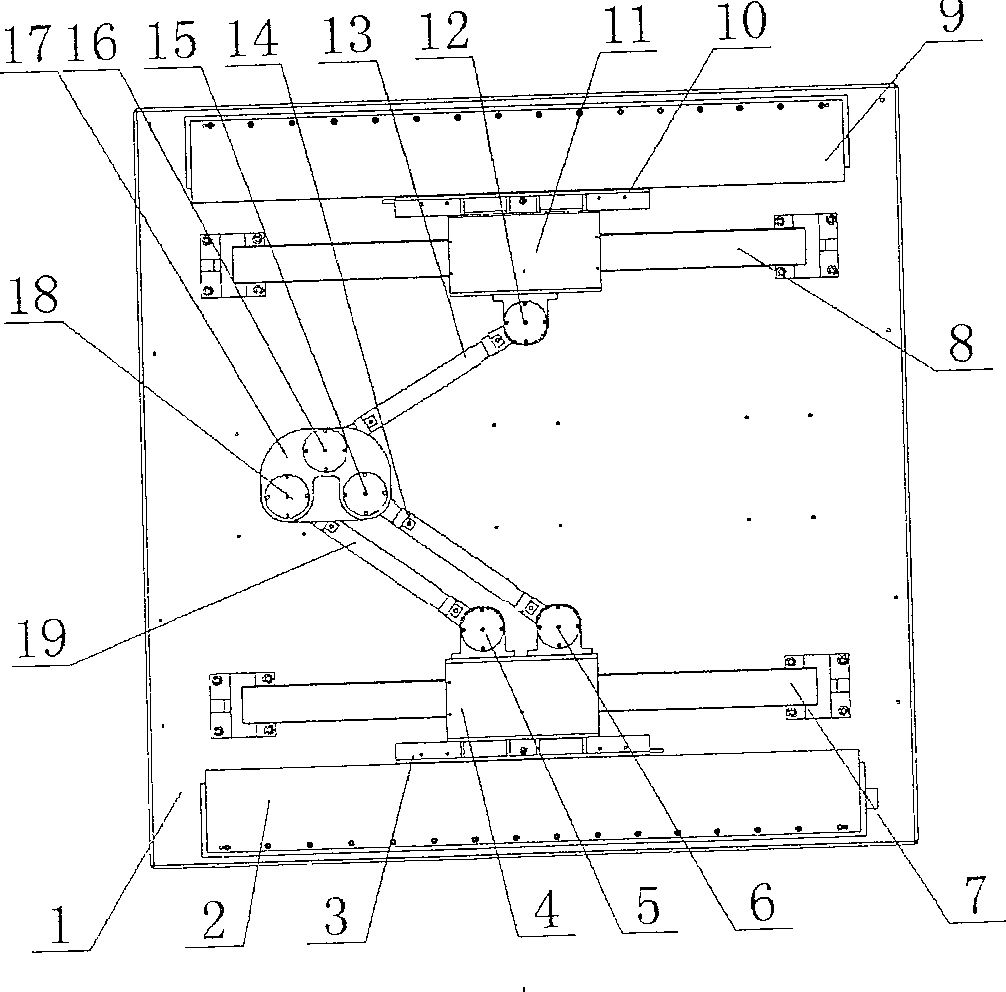

[0028] like figure 1 , 2As shown, the present embodiment includes: fixed platform 1, moving platform 17, three link mechanisms connecting fixed platform 1 and moving platform 17: first link mechanism 13, second link mechanism 14, third link mechanism 19 and six rotating hinges, two linear motors that can realize high-precision linear motion are installed on the fixed platform 1: the first linear motor 2 and the second linear motor 9, and the first linear motor 2 and the second linear motor 9 are symmetrical Placed in parallel, one end of the moving platform 17 is connected to the second linear motor 9 through a kinematic branch chain: the fifth rotating hinge 16, the first linkage mechanism 13, and the third rotating hinge 12, and the other end is respectively passed through two kinematic branch chains: the first The kinematic branch chain that four rotary hinges 15, the second link mechanism 14 and the second rotary hinge 6 constitute and the kinematic branch chain that the ...

Embodiment 2

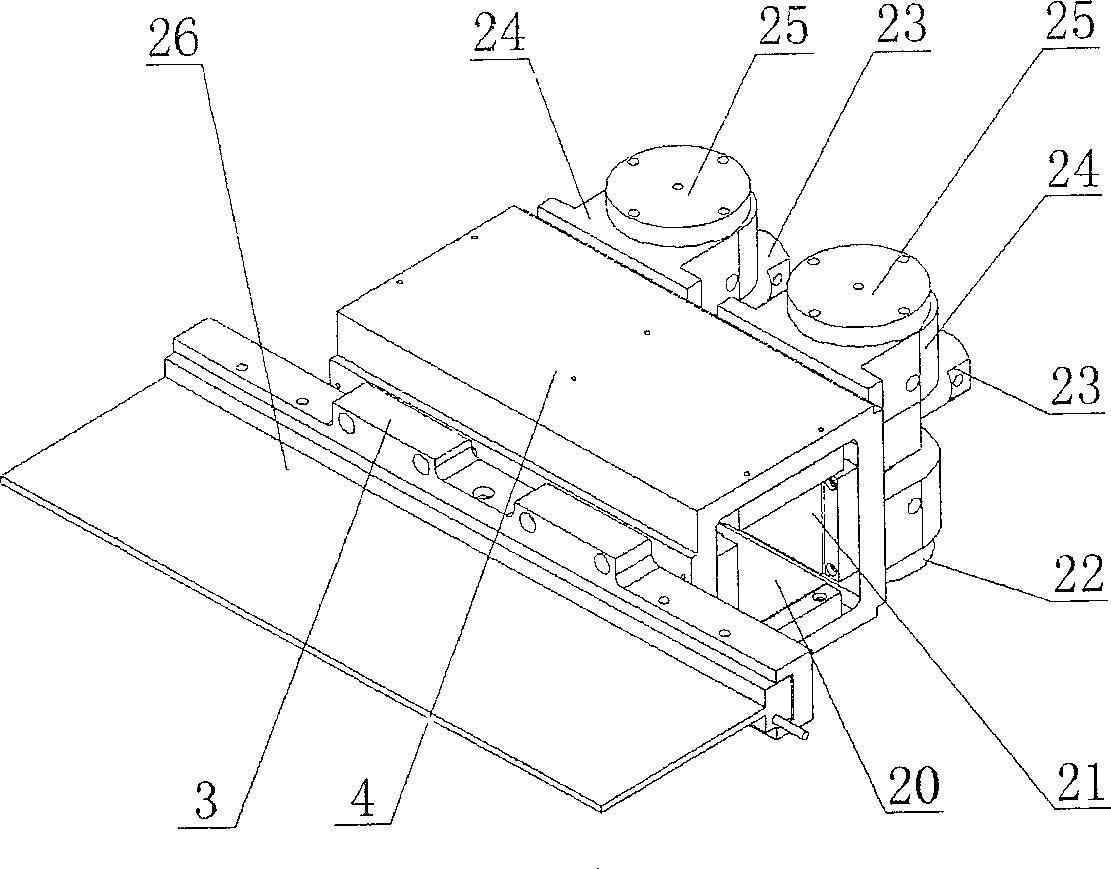

[0038] like Figure 7 , 8 As shown, on the basis of Embodiment 1, a fourth linkage mechanism 36 and two rotary hinges can be added without changing the movement form of the mechanism: the seventh rotary hinge 35 and the eighth rotary hinge 37 constitute redundant drive The two-degree-of-freedom planar parallel robot mechanism includes: a fixed platform 1, a symmetrical dynamic platform 38 (that is, the dynamic platform 17 in Embodiment 1) and four linkage mechanisms connecting the fixed platform 1 and the symmetrical dynamic platform 38: the first linkage Rod mechanism 13, second link mechanism 14, third link mechanism 19 and fourth link mechanism 36 and eight rotary hinges. One end of the symmetrical moving platform 38 is passed through two kinematic branch chains: the kinematic branch chain formed by the fourth rotary hinge 15, the second link mechanism 14, and the second rotary hinge 6; the sixth rotary hinge 18, the third link mechanism 19, the second rotary hinge A kine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com