Method for large-scale preparing ZnO nano bar array

A nanorod array, large-scale preparation technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of harsh preparation conditions, template removal, environmental pollution, etc., and achieve simple equipment, easy operation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

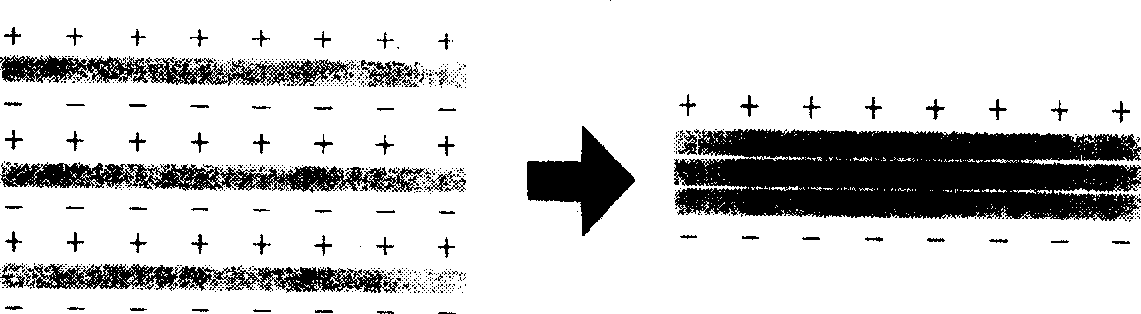

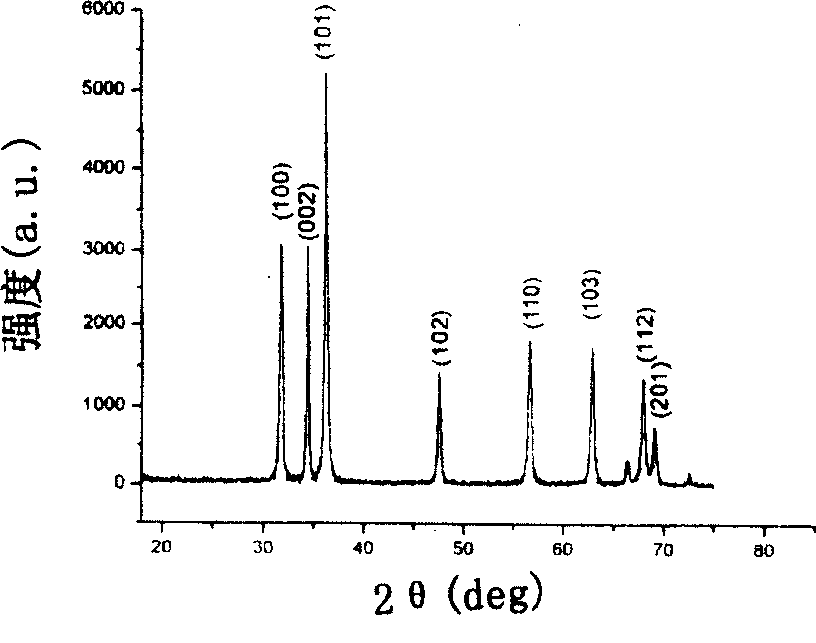

[0031] Embodiment 1: the method for preparing ZnO nanorod array on a large scale, its technological process is:

[0032] (1) According to the weight ratio of zinc acetate and water as 2:6, take a certain amount of zinc acetate and dissolve it in a certain amount of water to obtain solution A; according to the weight ratio of ethanol and citric acid as 79:6, take a certain amount of ethanol and add In a suitable citric acid, solution B was obtained;

[0033] (2) After uniformly mixing solution A and solution B, put them in a magnetic stirrer, and heat them in a water bath with a temperature of 60°C for 10 hours;

[0034] (3) drying in a drying oven at 75°C for 10 hours to obtain a white precursor;

[0035] (4) Put the white precursor in a muffle furnace and calcinate it at 400°C for 2.5 hours to obtain it.

Embodiment 2

[0036] Embodiment 2: the method for preparing ZnO nanorod array on a large scale, its technological process is:

[0037] (1) According to the weight ratio of zinc acetate and water as 2:12, take a certain amount of zinc acetate and dissolve it in a certain amount of water to obtain solution A; according to the weight ratio of ethanol and citric acid as 79:1, take a certain amount of ethanol and add In suitable citric acid, solution B is obtained; (0.1, 5 takes the lower limit)

[0038] (2) After uniformly mixing solution A and solution B, put them in a magnetic stirrer, and heat in a water bath with a temperature of 90°C for 8 hours;

[0039] (3) drying in a drying oven at 85°C for 5 hours to obtain a white precursor;

[0040] (4) Put the white precursor in a muffle furnace and calcinate it at 800°C for 1.5 hours to obtain it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com