Method for mfg. of nuclear track microhole comprehensive anti-fake mark and product

A technology of anti-counterfeiting marks and manufacturing methods, which is applied in the field of anti-counterfeiting, can solve the problems of poor aesthetics of nuclear microporous anti-counterfeiting marks and the influence of application range, and achieve the effects of easy control and management, maintenance of reputation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

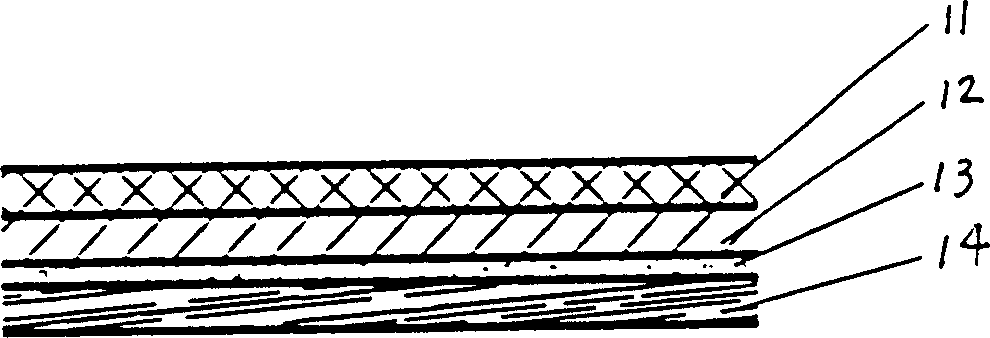

[0026] Example 1 The manufacturing method of the integrated anti-counterfeiting mark of ternary integrated nuclear micropore

[0027] The method for manufacturing the integrated anti-counterfeiting mark of ternary integrated nuclear micropores in this embodiment can basically be divided into five relatively independent steps:

[0028] 1. Heavy ion irradiation Use S-32 heavy ions with a total energy of 120 Mev produced by a heavy ion accelerator to irradiate a 28 μm thick transparent polyethylene terephthalate (PET) film in an irradiation vacuum chamber. The heavy ion beam intensity is 100nA, the electromagnetic scanning width is 40cm, and the film running speed is 25m / min. The heavy ion irradiation process is a disordered random process, so nuclear latent traces obeying the statistical law are formed in the irradiated PET film.

[0029] 2. Laser rainbow molded holographic image production This step is completely independent from the above step 1, which is convenient for contr...

Embodiment 2

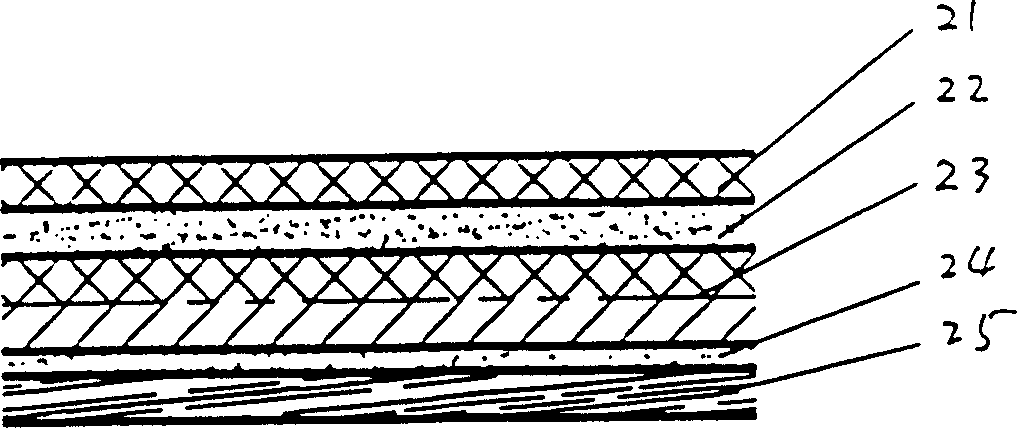

[0037] Manufacturing method of integrated anti-counterfeiting label of binary integrated nuclear micropore

[0038] The dual integrated nuclear microporous comprehensive anti-counterfeiting mark is derived from the ternary integrated anti-counterfeiting product with the same technical performance but different from each other. The method for manufacturing the integrated anti-counterfeiting mark of binary integrated nuclear micropores of the present invention can basically be divided into 5 relatively independent steps:

[0039] 1, heavy ion irradiation; this step is identical with the step 1 of embodiment 1

[0040] 2. Fabrication of laser rainbow embossed holographic images; this step is the same as step 2 of embodiment 1.

[0041] 3. Printing anti-counterfeiting marks; this step is basically the same as Step 3 of Embodiment 1. The difference is that the nuclear microhole pattern and characters are distributed in a certain sequence to ensure that each laser holographic anti...

Embodiment 3

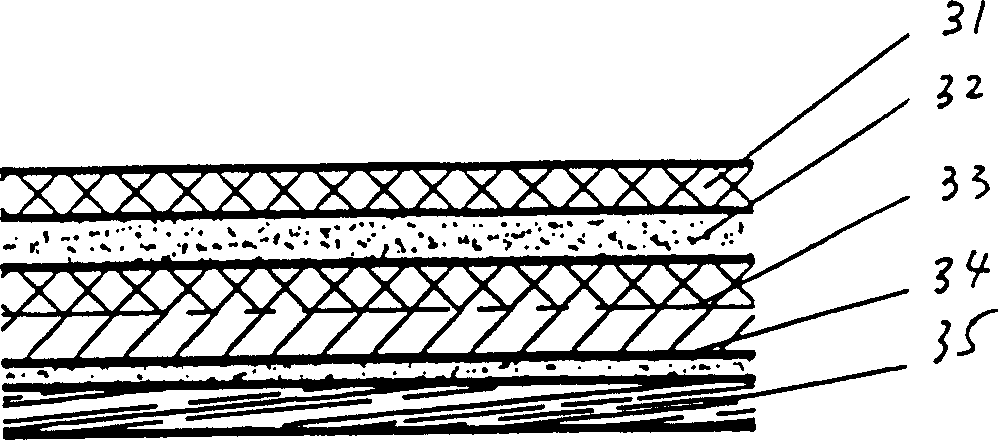

[0045] Example 3 Manufacturing method of composite nuclear microporous anti-counterfeiting label

[0046] The composite nuclear micropore anti-counterfeiting mark is derived from the binary integrated nuclear micropore anti-counterfeiting mark, and is an anti-counterfeiting product with the same technical performance but not the same. Basically, it can be divided into 5 relatively independent steps:

[0047] 1. Heavy ion irradiation This step is the same as step 1 of the embodiment.

[0048] 2. Anti-counterfeiting mark of microporous printing on the concave sheet This step is the same as Step 3 of Example 2.

[0049] 3. Chemical etching of nuclear micropores This step is the same as Step 4 of Example 1.

[0050] 4. Production of laser iridescent holographic anti-counterfeiting marks Applying laser iridescent holographic plate-making technology and molding replication technology to make laser iridescent embossed holographic image anti-counterfeiting marks on ordinary PET alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com