Pre-mixing type whirl combustion apparatus

A swirl burner and premixed technology, which is applied in the field of kitchen stoves, can solve the problems of affecting the kitchen environment, waste of energy, and inability to reflect the energy saving effect, so as to improve the kitchen environment, shorten the processing time, and achieve an ideal combustion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

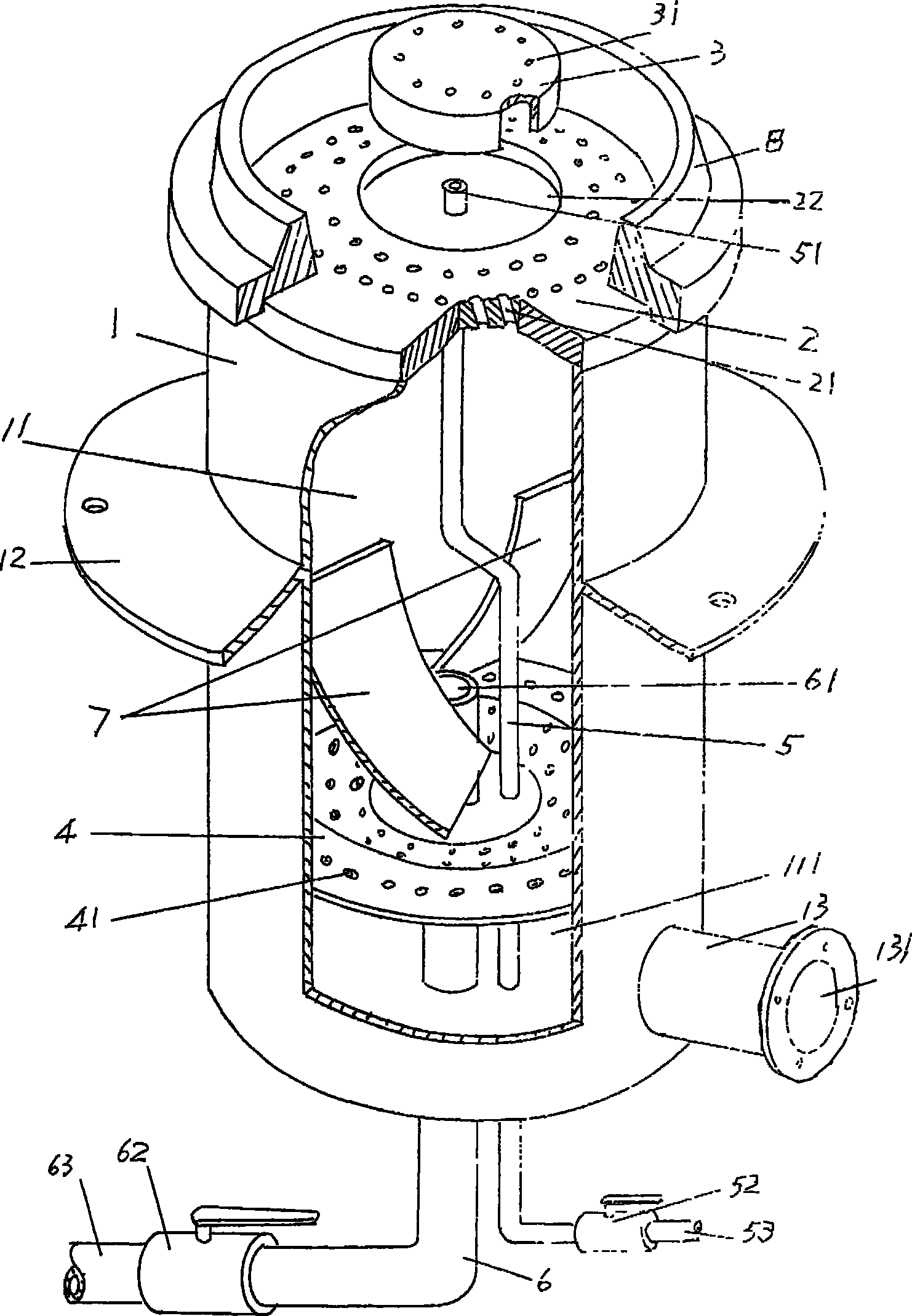

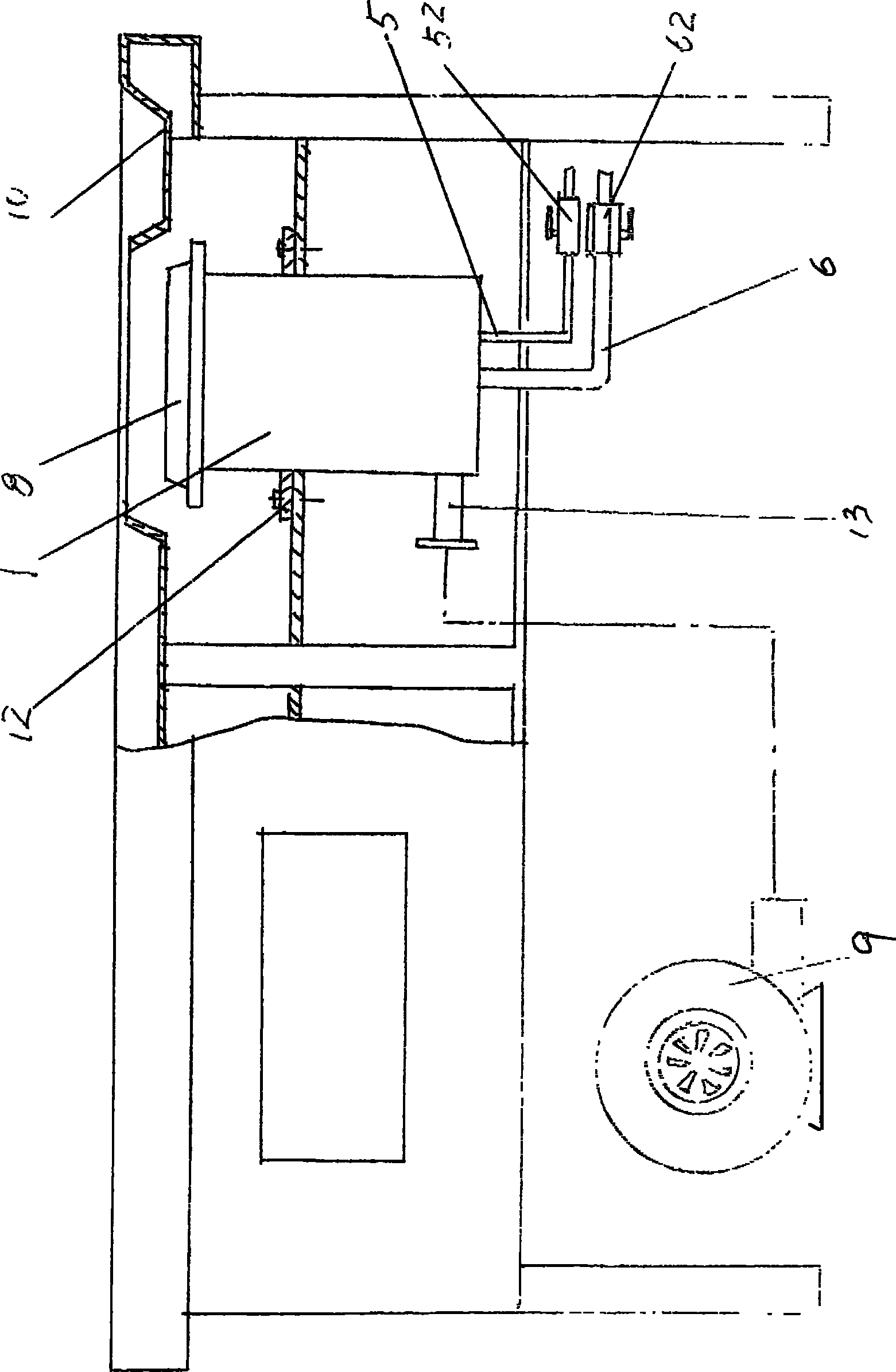

[0012] In order to enable the examiners of the patent office, especially the public, to further understand the structural features and beneficial effects of the present invention, the applicant specifically describes the specific implementation of the present invention in detail as follows in conjunction with the accompanying drawings and examples:

[0013] see figure 1 , a mixed gas cylinder body 1 made of metal and preferably cylindrical in shape is provided, the mixed gas cylinder body 1 is completely hollow, thereby forming a mixed gas cavity 11, the bottom of the mixed gas cavity 11 should be closed while the upper part is open. A fixed seat 12 is extended on the outer wall of the mixed gas cylinder 1 and above. According to this embodiment, the recommended fixed seat 12 is like a flange, so it is a specific form of fixed disk; if it is changed to surround the mixed gas cylinder A plurality of fixed feet of the body 1 is also completely feasible, so it is known that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com