Telescopic support leg for travel machine and concrete pump truck with the same

A concrete pump truck, telescopic technology, applied in the direction of cranes, vehicle maintenance, lifting vehicle accessories, etc., can solve the problems of poor force, poor support rigidity and stability, large deformation of the support arm, etc., to improve the force and rigidity , good force characteristics, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

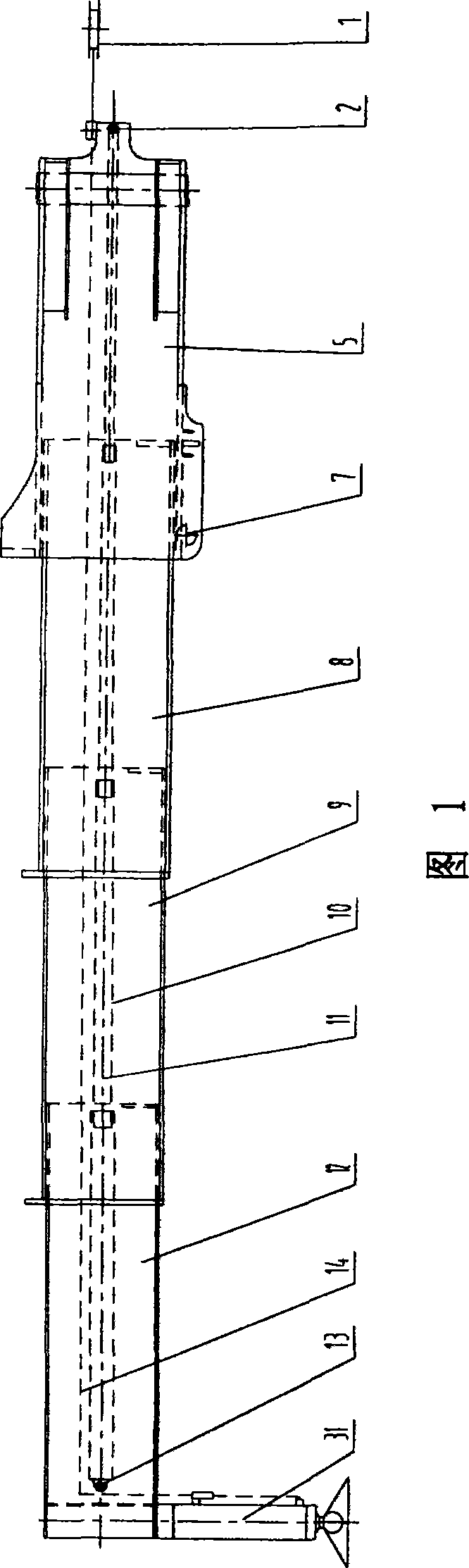

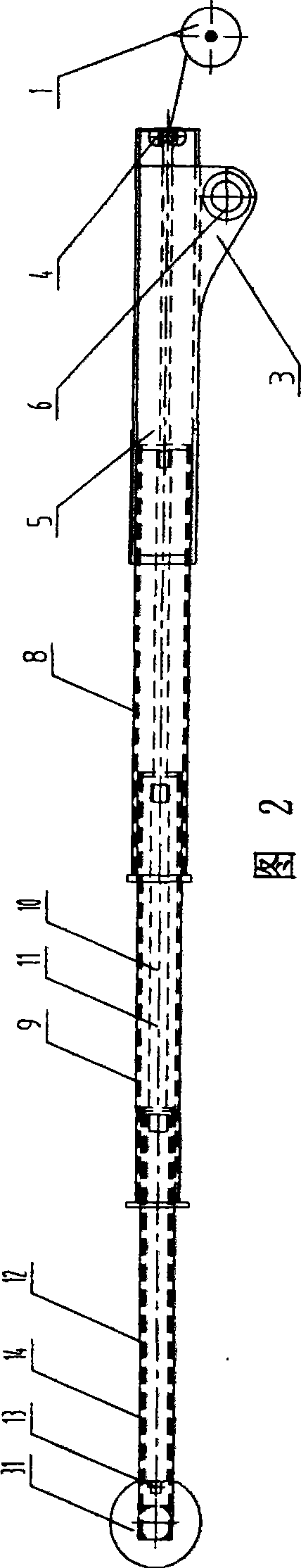

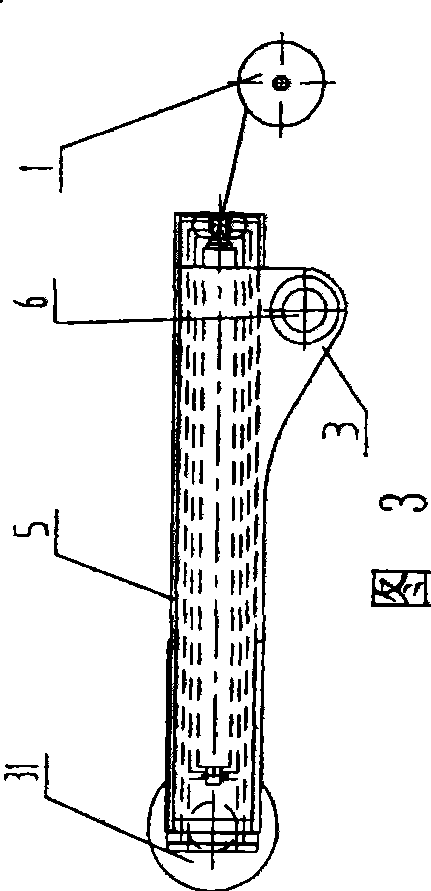

[0044] The schematic diagram of the structure of the telescopic outrigger shown in Figure 1, Figure 2 and Figure 3 and Figure 6As shown in Fig. 7, the state schematic diagram of the support leg installed on the concrete pump truck, the telescopic support leg used for walking machinery of the present invention includes a support leg box 5 that is connected to the chassis 20 and can deflect around the rotating shaft 6 1. A sleeve part that can be telescopic in the outrigger box body 5 and a foot part 31 that is installed on the front end of the sleeve part and can be vertically telescopic. A double-acting hydraulic cylinder 10 is arranged inside the outrigger box body 5 and the sleeve-type part, and the two ends of the hydraulic cylinder 10 are respectively fixed on the fixed point 2 at the end of the outrigger box body 5 and the farth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com