Micro-structure twist fatigue testing apparatus driven by parallel plate capacitance

A parallel plate capacitance and torsional fatigue technology, which is used in the testing of measuring devices, machine/structural components, and the use of stable torsional force to test the strength of materials. Easy-to-use, easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

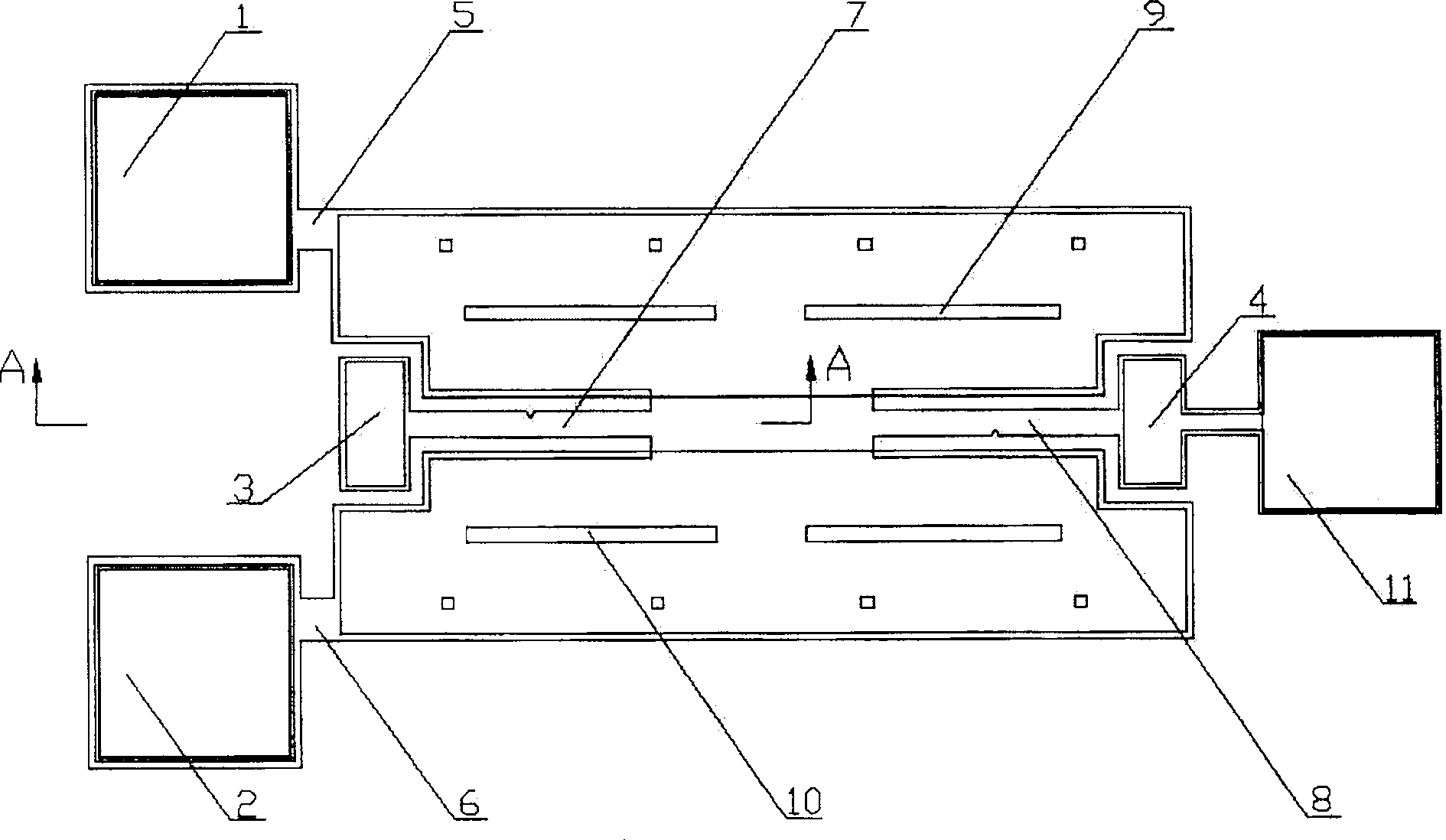

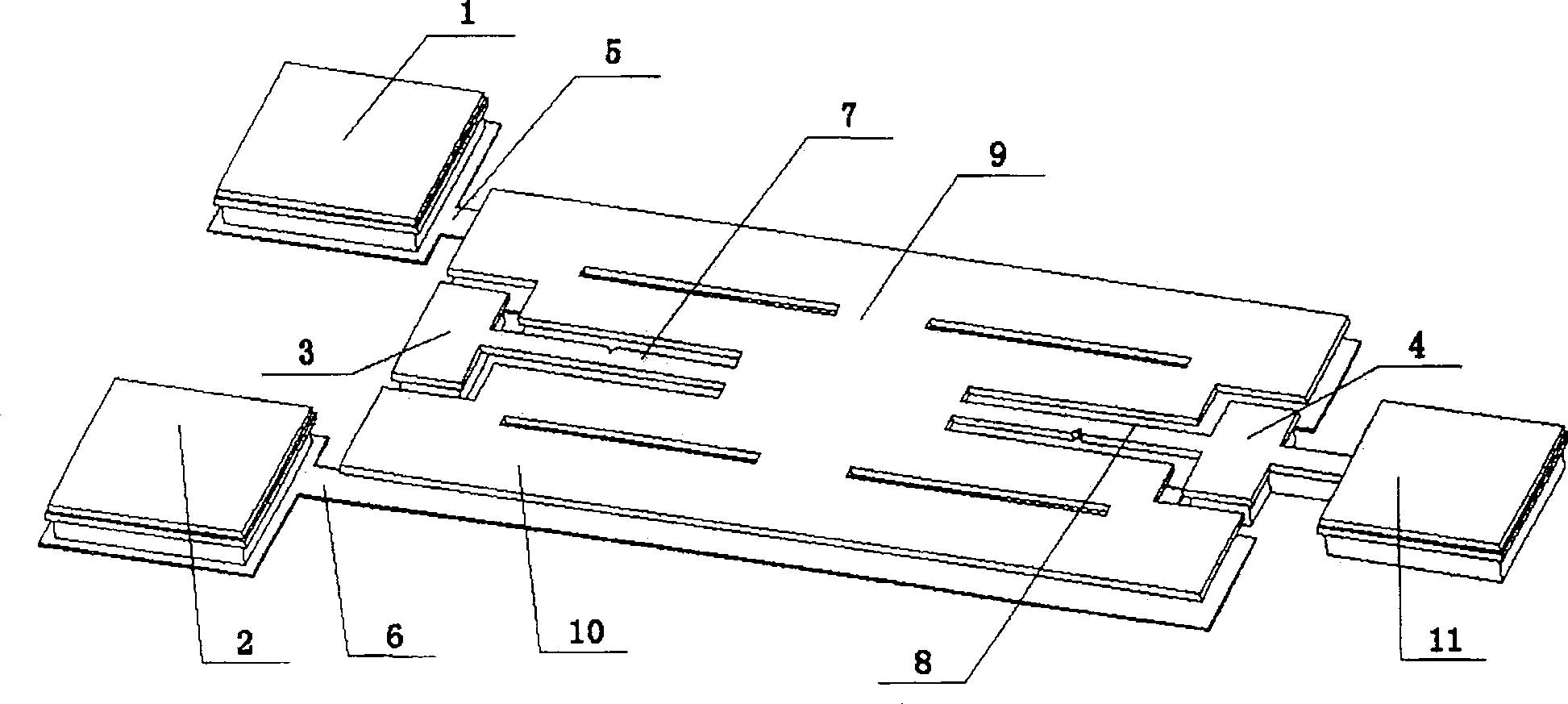

[0022] Attached below Figure 1~4 Specific examples of the present invention will be described.

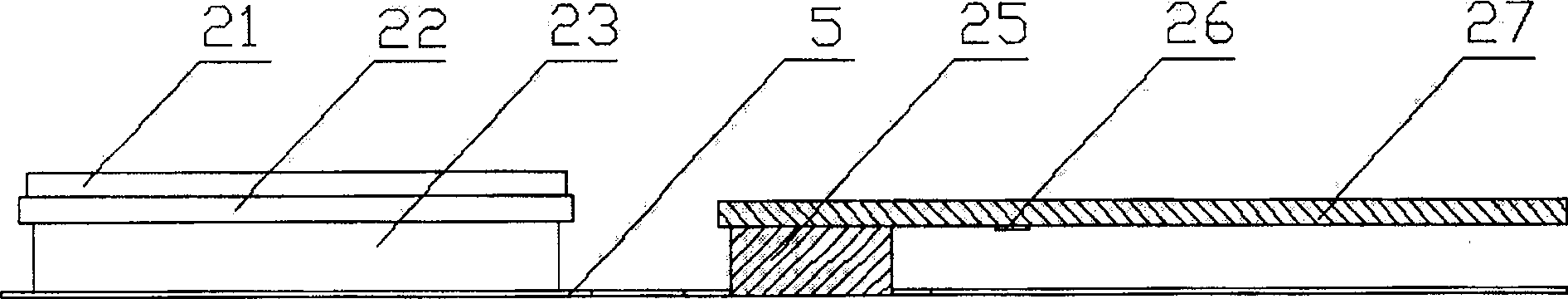

[0023] There are three electrodes in this embodiment, wherein the driving electrode 1 is connected to an alternating current, and the bottom electrode layer 5 of the electrode and the first suspended plate 9 form a parallel-plate capacitive driver to realize the vertical driving of the first suspended plate 9 . The bottom electrode layer 6 of the detection electrode 2 and the second suspended parallel plate 10 constitute a parallel plate capacitive sensor, and the change of the distance between the second suspended plate 10 and the second bottom electrode 6 during the experiment is obtained by connecting an external amplitude detection circuit. That is, the change in capacitance. The ground electrode 11 is grounded. Cantilever beam samples 7 and 8 are cantilever beams on the central axis of the suspended plate, one end of which is connected to the fixed block, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com