Induction coil of electromagnetic drinking water boiler

A technology of induction coils and boiling water boilers, which is applied in the direction of coil devices, induction heating, induction heating devices, etc., can solve the problems of easy smoking, poor safety and reliability, etc., and achieve the effects of not easy smoking, simple structure, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

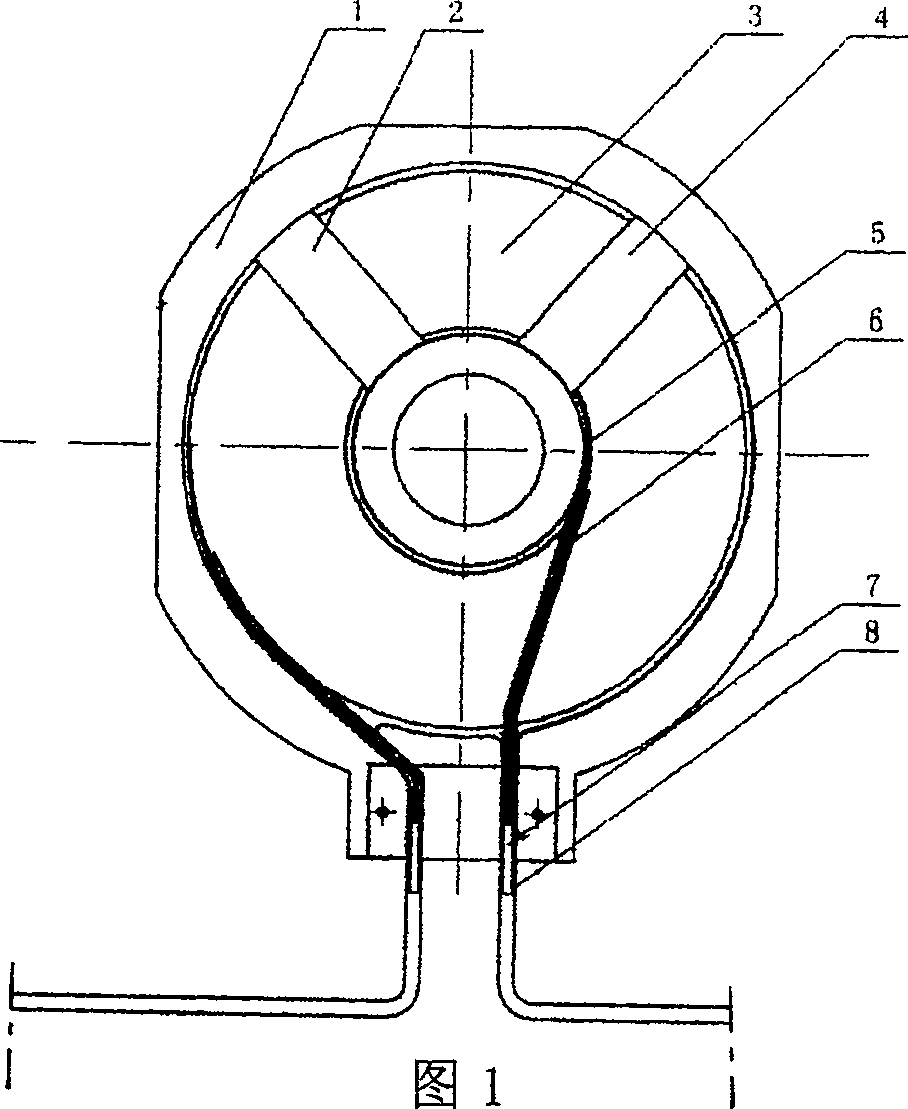

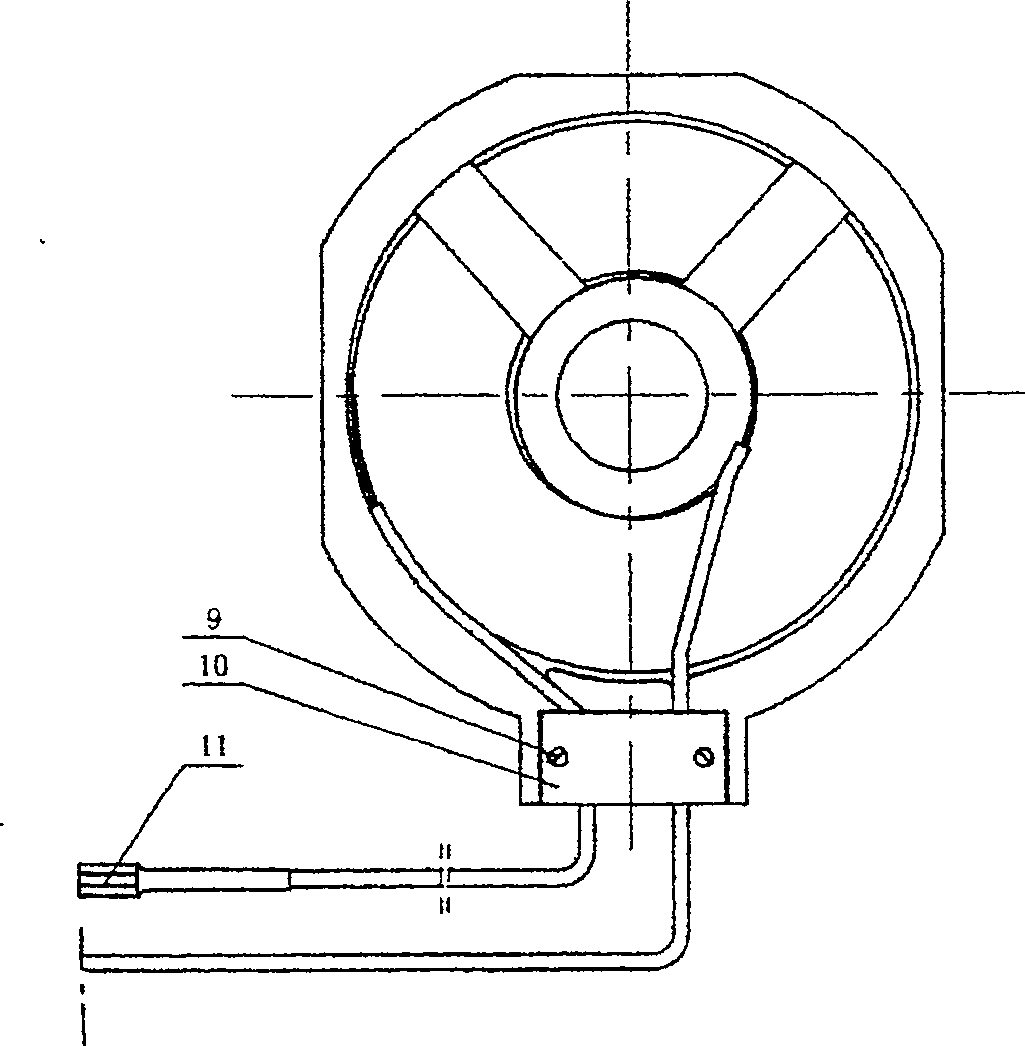

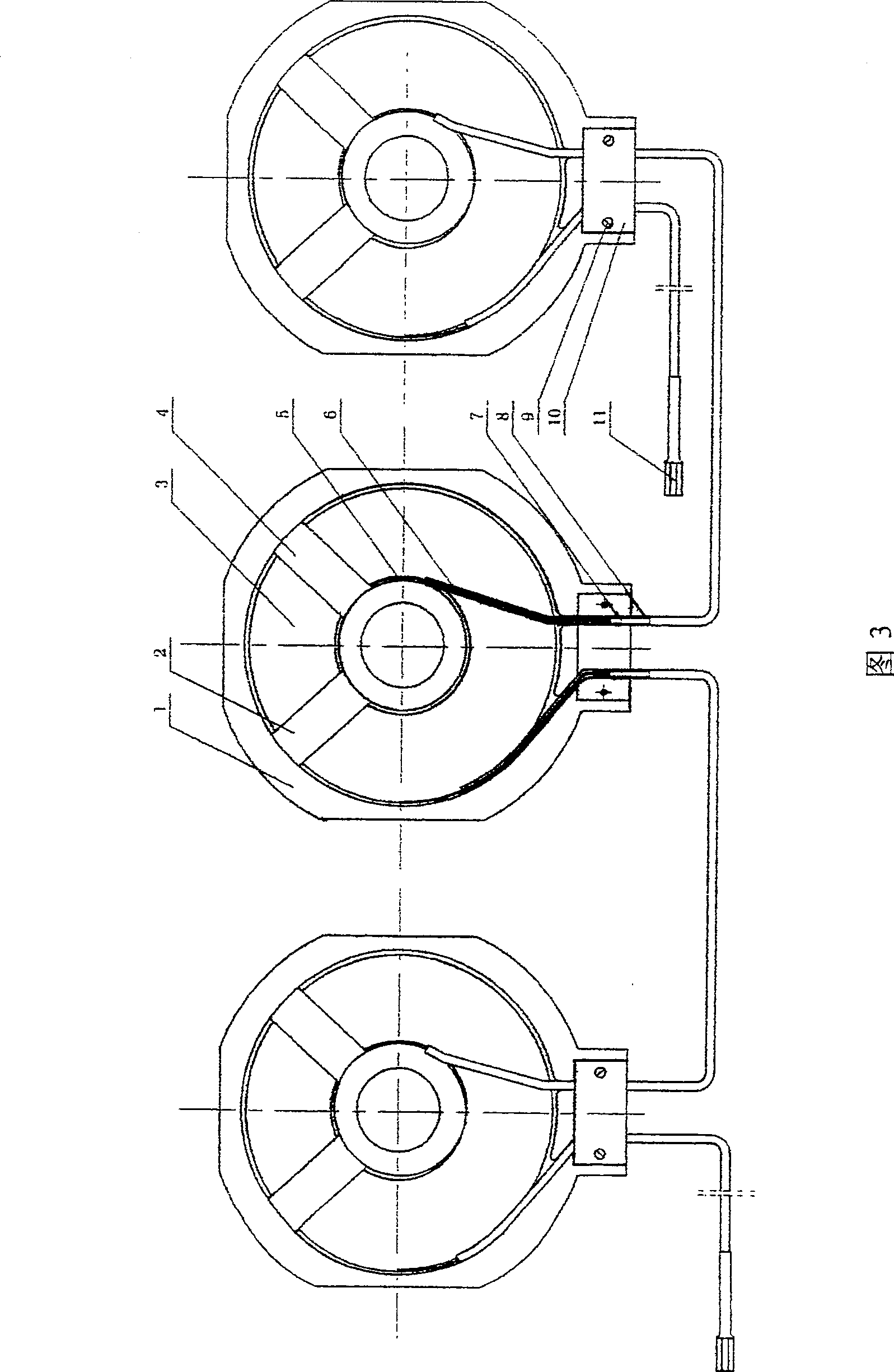

[0011] The present invention mainly consists of protection plate 1, bead 2, 4, coil 3, heat-shrinkable sleeve 5, polytetrafluoroethylene sleeve 6, low-smoke halogen-free wire 7, glass fiber self-extinguishing tube 8, screw 9, cover plate 10, insert spring 11 etc. are formed.

[0012] The thickness of the silk-covered wire used in the present invention is: 1.1±0.03mm, and the width is: 3.4±0.03mm. The total number of coils of coil 3 is 36.5-37.5 coils, and the inner diameter is 63-67mm. Coil inductance L = 165 ~ 175uH, Q value greater than 50. Put the coil 3 into the protection plate 1, connect the lead wire of the coil 3 to the center of the cover plate, and cut it off. On this basis, weld two 2.5 square millimeter low-smoke and halogen-free wires 7 to the lead wire of the coil 3. 3. The heat-shrinkable sleeve 5 and the polytetrafluoroethylene sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com