Positioning method and apparatus for pushing carbon block from transfer line rotary platform to receiving arrangement

A technology of rotating platform and receiving device, applied in conveyor control device, conveyor objects, transportation and packaging, etc., can solve problems such as poor work reliability, carbon block jam, equipment damage, etc., achieve accurate detection and positioning, and improve work efficiency. Efficiency, the effect of reducing the damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

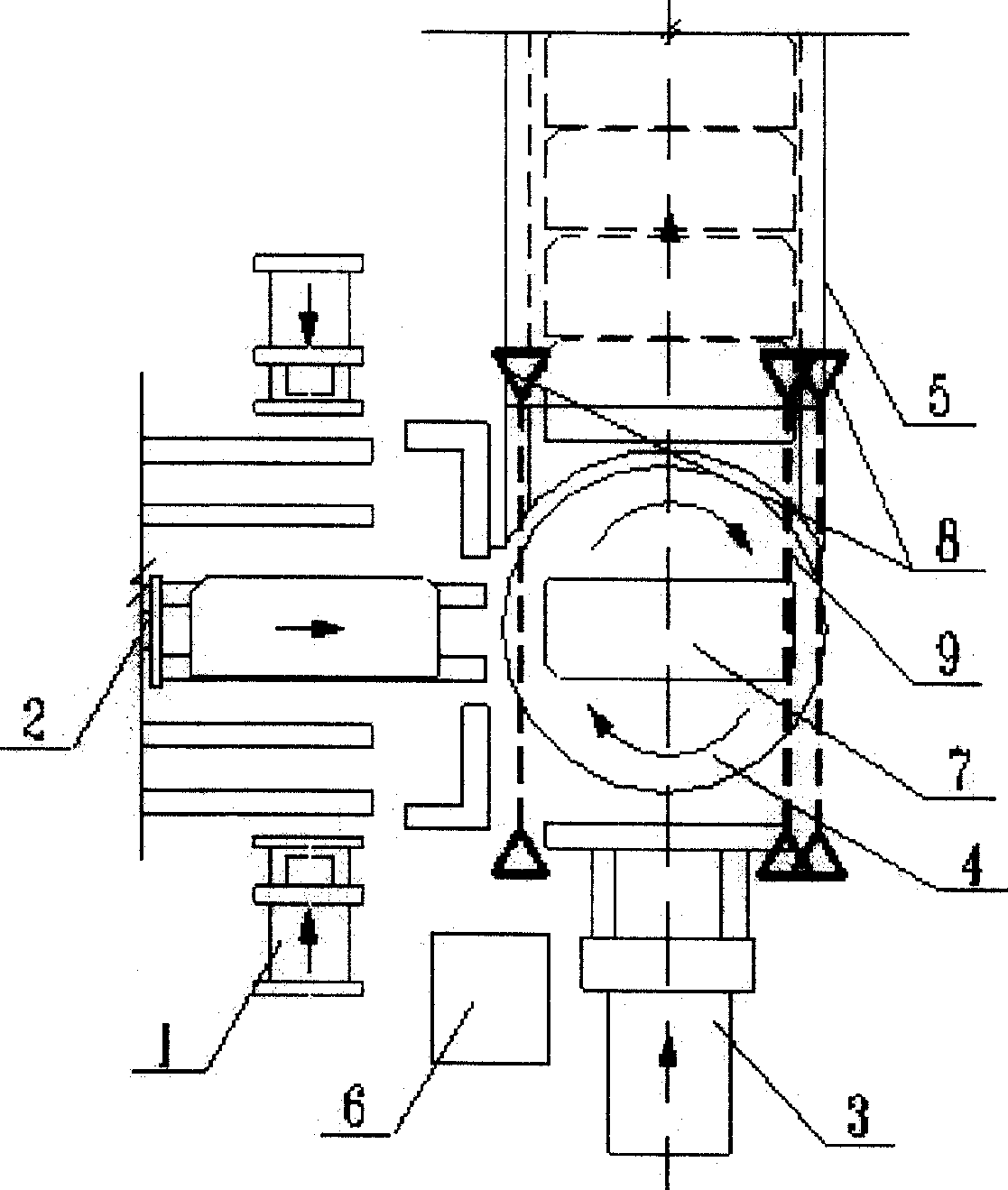

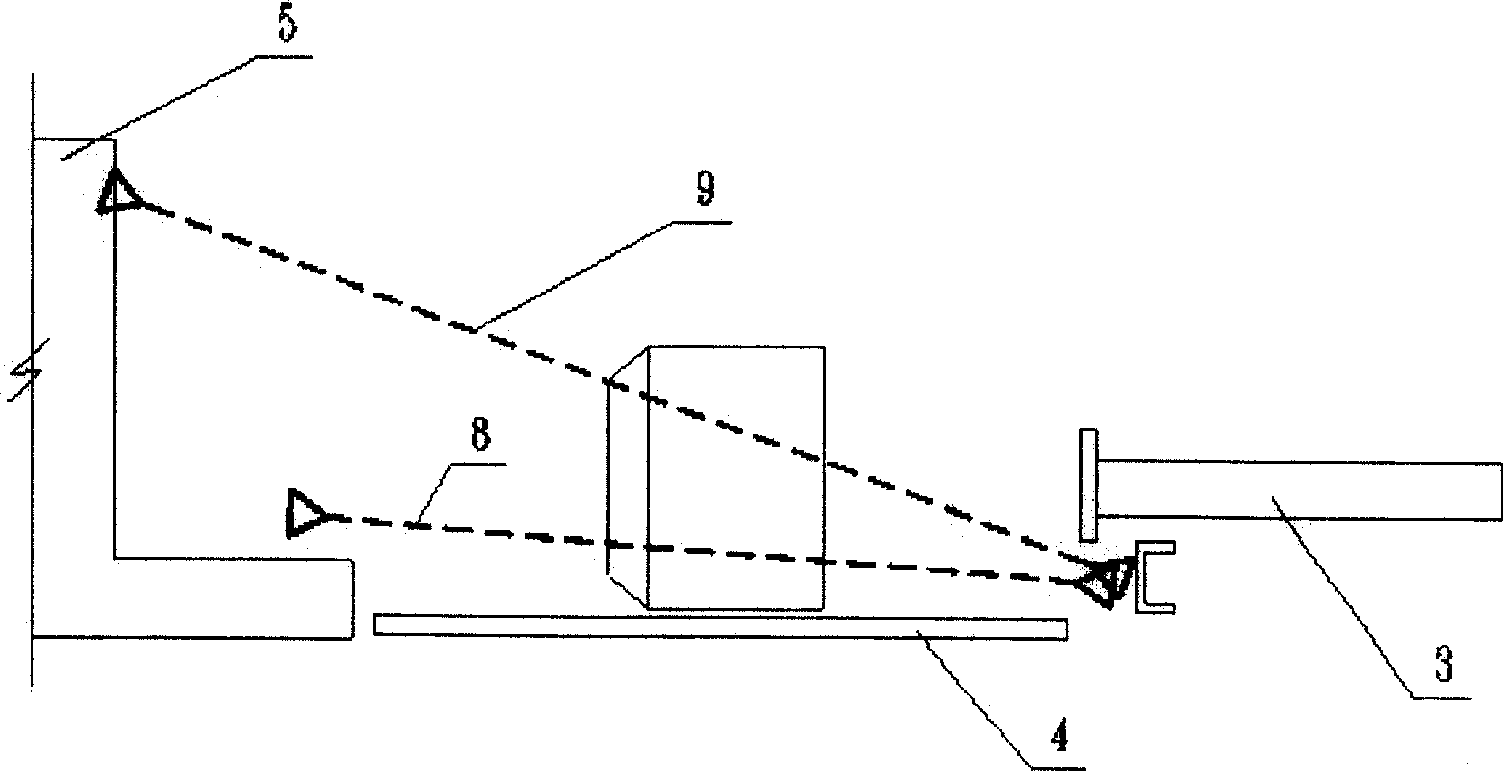

[0011] Embodiments of the present invention: the present invention can be directly applied to the propulsion cylinder 2 containing the conveying device 1, the rotating platform 4, the receiving device 5 and the carbon block 7 on the conveying device 1 onto the rotating platform 4 and the rotating platform 4 The charcoal block 7 on the top is released to the ejection cylinder 3 on the receiving device 5 and the carbon block grouping machine or ungrouping machine in the prior art of the control device 6 that controls the actions of these parts is improved in production. A pair of photoelectric switches 8 for preventing the deflection of the carbon block are respectively installed on both sides of 4, and a pair of photoelectric switches 9 for detecting the carbon block in place are installed between the two pairs of anti-deflection photoelectric switches 8, and the two pairs of anti-deflection The output signals of the photoelectric switch 8 and a pair of photoelectric switches 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com