Making process of decorating konjaku plate

A manufacturing method and board material technology, applied in the field of manufacturing konjac board decoration materials, can solve the problems of unfavorable environmental protection, high price, and damage to the environment, and achieve the effects of protecting the environment, respecting nature, and reducing the source of triggers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0018] A kind of manufacture method of decorative konjac plate material is characterized in that, manufacture according to the following steps:

[0019] (1) mixing and stirring the konjac powder that is 5-6 parts by weight and 200-240 parts by weight, heated to 90°C;

[0020] (2) adding 10-20 parts by weight of straw powder, mixing and stirring;

[0021] (3) add the gypsum powder that is 6-10 parts by weight again, stir after mixing;

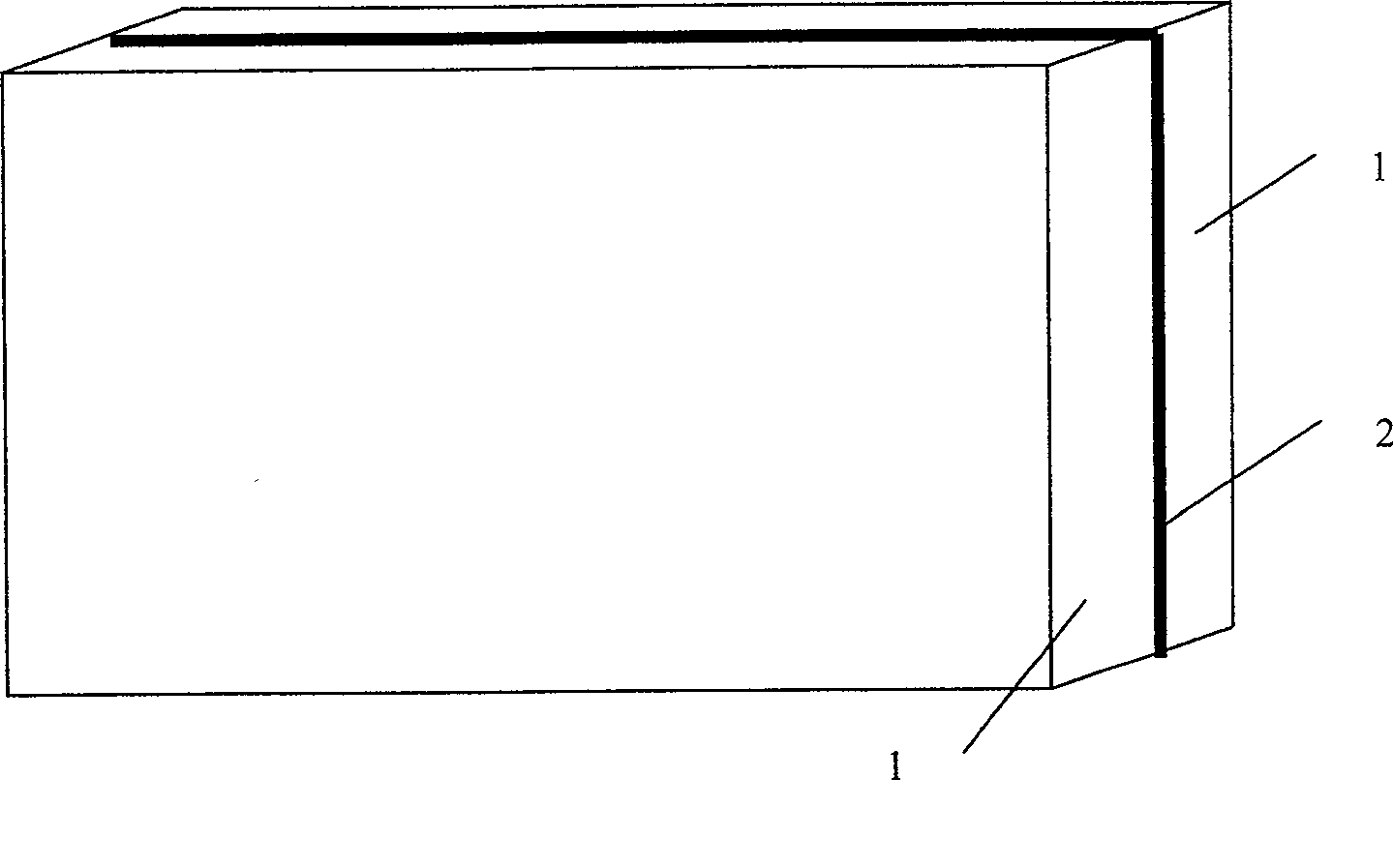

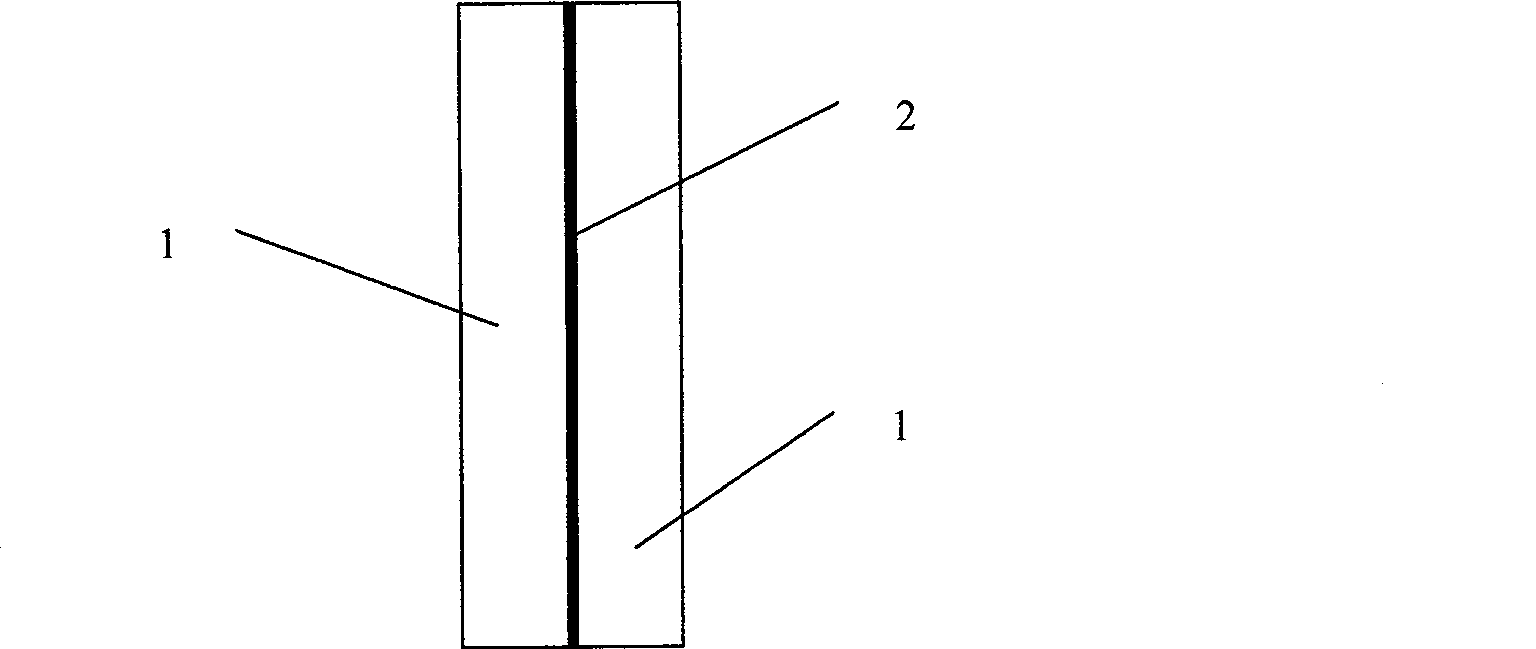

[0022] (4) Select iron sand nets of corresponding specifications according to the size requirements of the specific materials used, and apply the konjac powder mixture on both sides of the iron sand nets;

[0023] (5) Press the konjac board with a template, and dry and form it.

Embodiment ( 2

[0025] A kind of manufacture method of konjac board material for decoration, manufacture according to the following steps:

[0026] (1) the konjac powder that is 6 parts by weight and the water that is 240 parts by weight are mixed and stirred, heated to 90 DEG C;

[0027] (2) adding 20 parts by weight of straw powder, mixing and stirring;

[0028] (3) Add 10 parts by weight of gypsum powder, stir after mixing;

[0029] (4) Select iron sand nets of corresponding specifications according to the size requirements of the specific materials used, and apply the konjac powder mixture on both sides of the iron sand nets;

[0030] (5) Press the konjac board with a template, and dry and form it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com