Engine

An engine and passage technology, which is applied to engine components, engine cooling, machine/engine, etc., can solve the problems of low cooling water cooling efficiency, poor circulation of cooling water, and rising pressure of cooling water tank 101.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

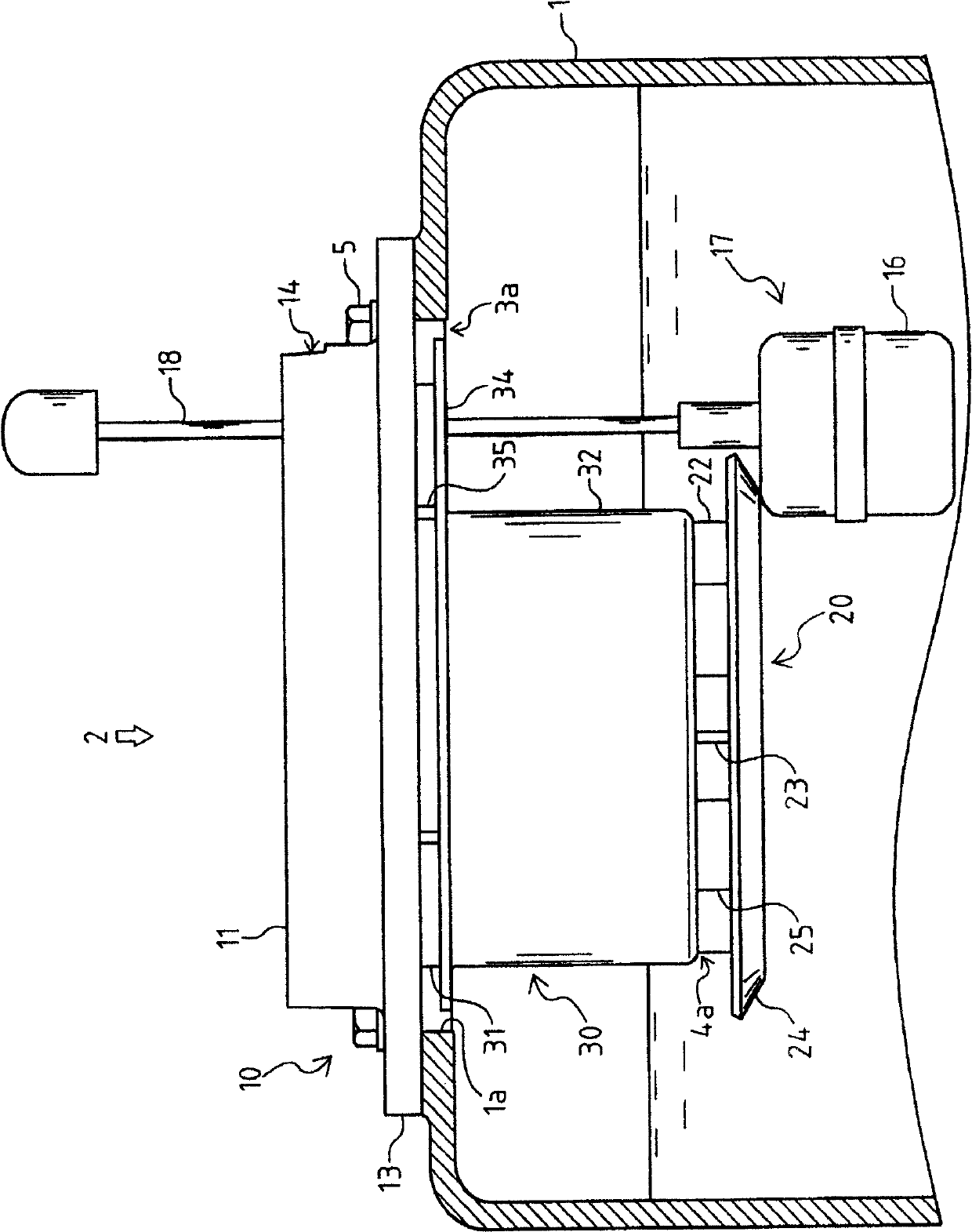

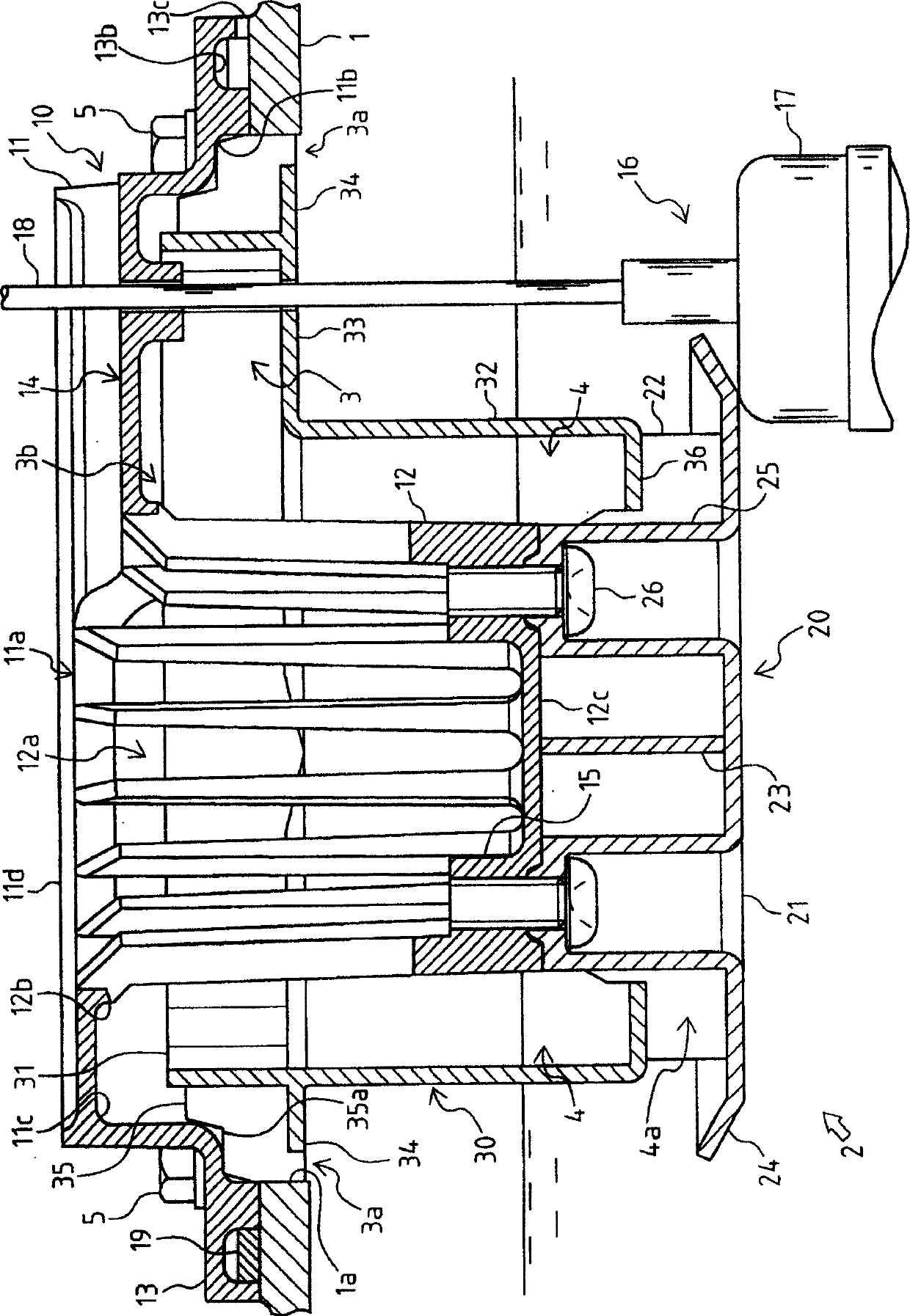

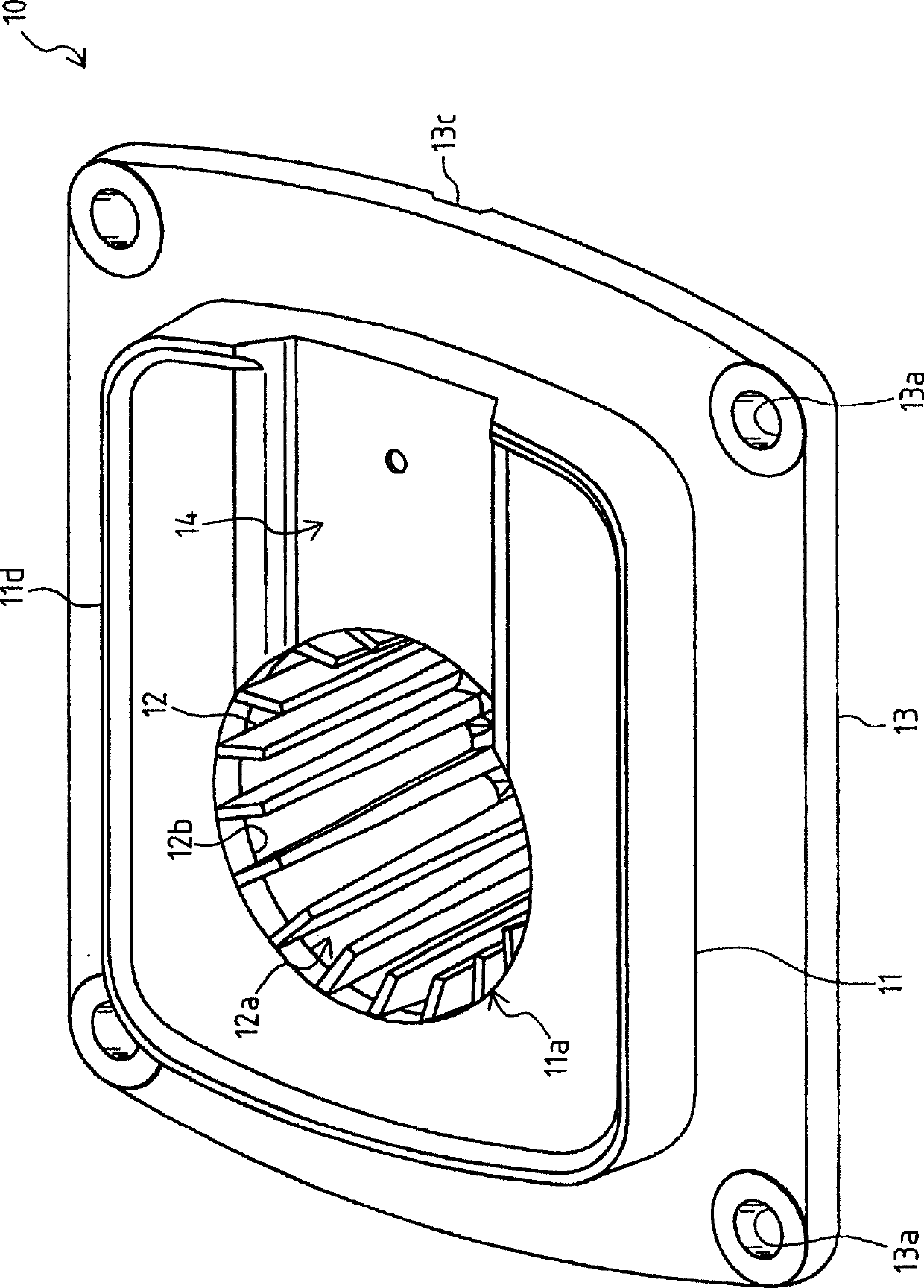

[0058] Figure 12 Shown is a water-cooled horizontal cylinder diesel engine 90 as an example of the present invention. This engine 90 has a horizontal cylinder 91 and a cylinder block in which a water cooling jacket (not shown) is formed and arranged around it. A crankcase 92 is arranged on the right side of the cylinder 91 in side view, and a crankcase 92 is arranged on the left side of the cylinder 91. Cylinder head and valve arm box 93 etc. are arranged on the side. In addition, the present invention is also applicable to any other internal combustion engines such as other vertical cylinder type diesel engines and gasoline engines as long as the cylinders are cooled by water.

[0059] And engine 90, dispose cooling water tank 1 above this cylinder block (and crank case 92), by communicating this cooling water tank 1 and the water cooling jacket that is arranged around cylinder 91, can make cooling water flow between cooling water tank 1 and water cooling jacket circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com