Low molecular weight copolymer dispersant and its preparing method

A low-molecular-weight, copolymer technology, applied in the chemical industry, can solve problems such as poor dispersion, complex production control, and cumbersome production, and achieve good dispersion retention performance, cheap and easy-to-obtain raw materials, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

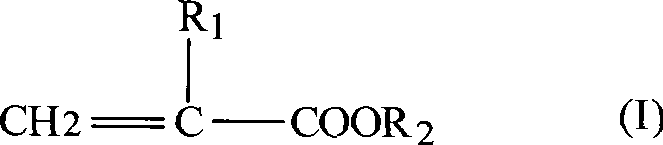

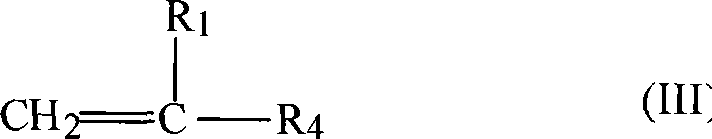

Method used

Image

Examples

Embodiment 1

[0041] In a 1L glass reactor equipped with a thermometer, a stirrer and a reflux condenser, add 400g of tap water, 90g (1.046mol) of methacrylic acid, 110g (0.846mol) of hydroxypropyl acrylate, and 35g (0.875mol) of sodium hydroxide in sequence , stirred into a homogeneous monomer aqueous solution, and heated up to 60 ° C, then 100 parts of an aqueous solution containing 4.5 g (0.0167 mol) of potassium persulfate was added to the reactor at one time, and the temperature in the reactor was observed to rise after 20 minutes. The solution becomes thicker, the stirring resistance increases, and finally the temperature naturally rises to 97°C, and is kept at this temperature for 2h, and 20 parts of an aqueous solution containing 1.0g (0.0037mol) of potassium persulfate is added, and kept warm for 1h, to obtain pH The value is 6.5, the solid content is 29.2% viscous liquid, and at 25°C, the polymer viscosity is 225mpa.s (P-1).

Embodiment 2

[0043] In a 1L glass reactor equipped with a thermometer, a stirrer and a reflux condenser, add 400g of tap water, 80g (1.111mol) of acrylic acid, 100g (0.767mol) of hydroxyethyl methacrylate, 20g (0.0965mol) of 2-propylene Amino-2-methylpropanesulfonic acid, 36g (0.90mol) sodium hydroxide, stirred into a uniform monomer aqueous solution, and heated to 50 ° C, and then 100 parts of the aqueous solution containing 18g (0.0789mol) ammonium persulfate once After 10 minutes, it is observed that the temperature in the reactor rises, the solution becomes thicker, and the stirring resistance increases. Finally, the temperature naturally rises to 95°C and is kept at this temperature for 2 hours. Add 20 parts containing 6.0 g (0.026mol) aqueous solution of ammonium persulfate, and continue to keep warm for 1h to obtain a viscous liquid with a pH value of 6.2 and a solid content of 30.1%. At 25°C, the viscosity of the polymer is 185mpa.s (P-2).

Embodiment 3

[0045] In a 1L glass reactor equipped with a thermometer, a stirrer and a reflux condenser, add 500g of tap water, 80g (0.93mol) of methacrylic acid, 90g (0.692mol) of hydroxypropyl acrylate, 10g (0.093mol) of ethylenesulfonic acid , 32g (0.80mol) sodium hydroxide, 54g (0.0874mol) methoxypolyethylene glycol methacrylate (general formula IV, n=12) were stirred into a uniform monomer aqueous solution, and the temperature was raised to 55°C, and then Add 100 parts of an aqueous solution containing 8g (0.0336mol) sodium persulfate into the reactor at one time. After 20 minutes, it is observed that the temperature in the reactor rises, the solution becomes thicker, the stirring resistance increases, and finally the temperature naturally rises to 98°C , and at this temperature for 2h, add 20 parts of an aqueous solution containing 2.0g (0.0084mol) sodium persulfate, and continue to insulate for 1h to obtain a pH value of 6.7, a viscous liquid with a solid content of 28.3%, at 25°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com