Reference voltage module and temperature compensating method thereof

A reference voltage and reference voltage circuit technology, applied in the field of reference voltage modules and their temperature compensation, can solve the problems of little improvement in temperature characteristics, difficulty in high-order temperature compensation, large output impedance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

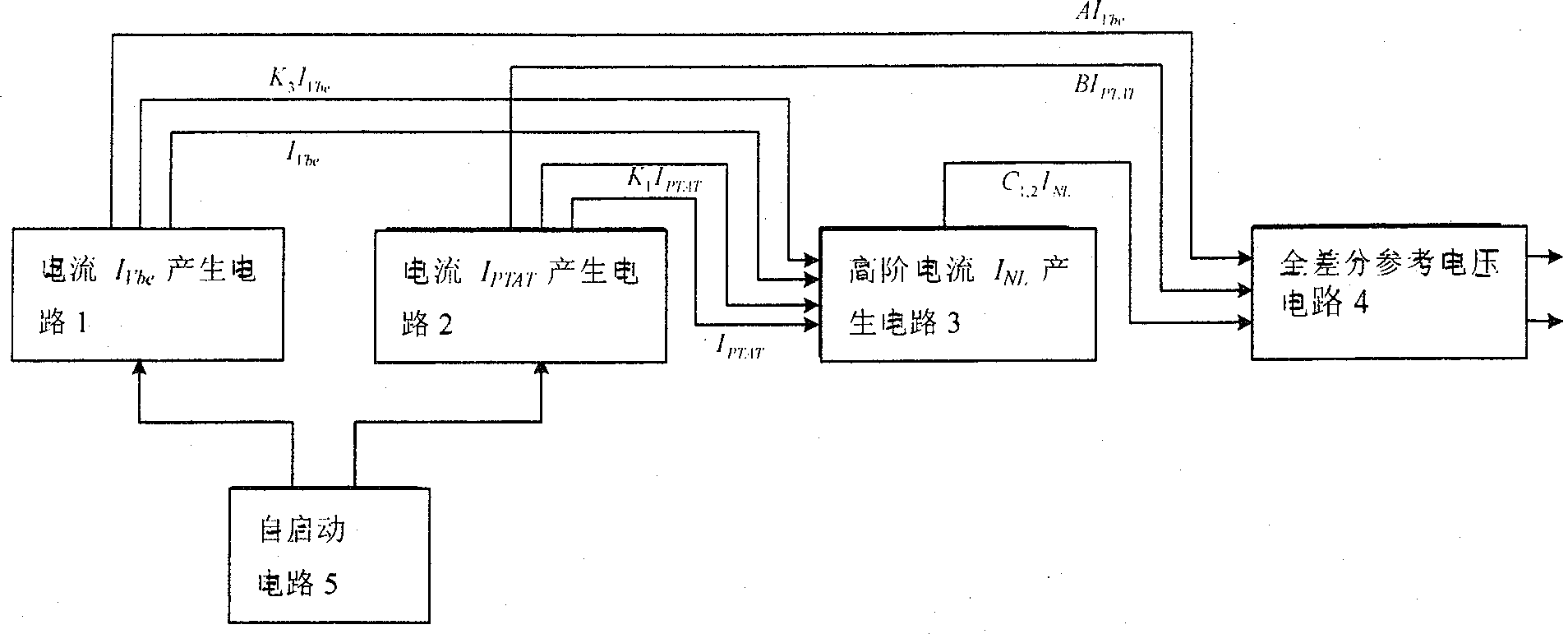

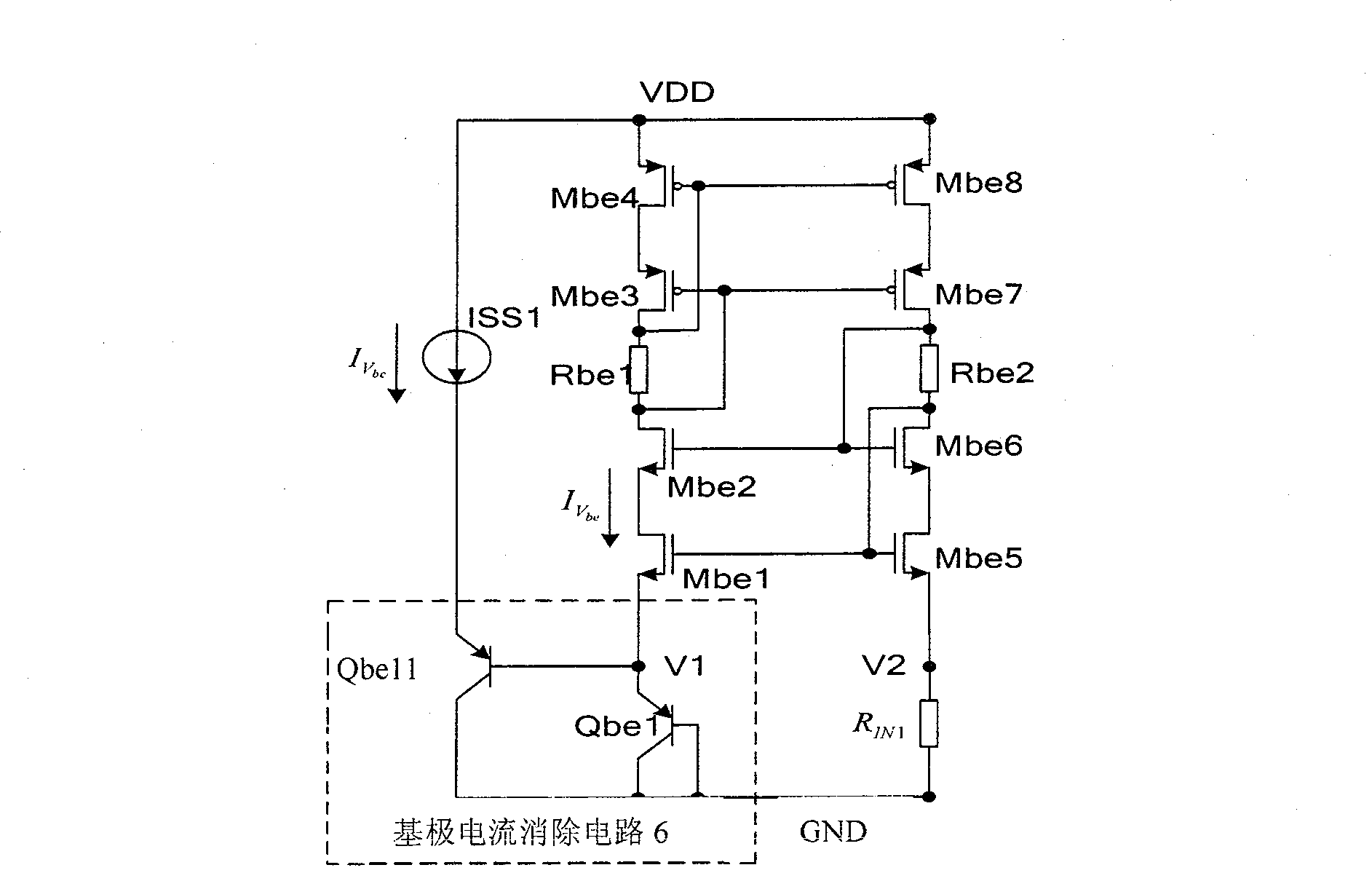

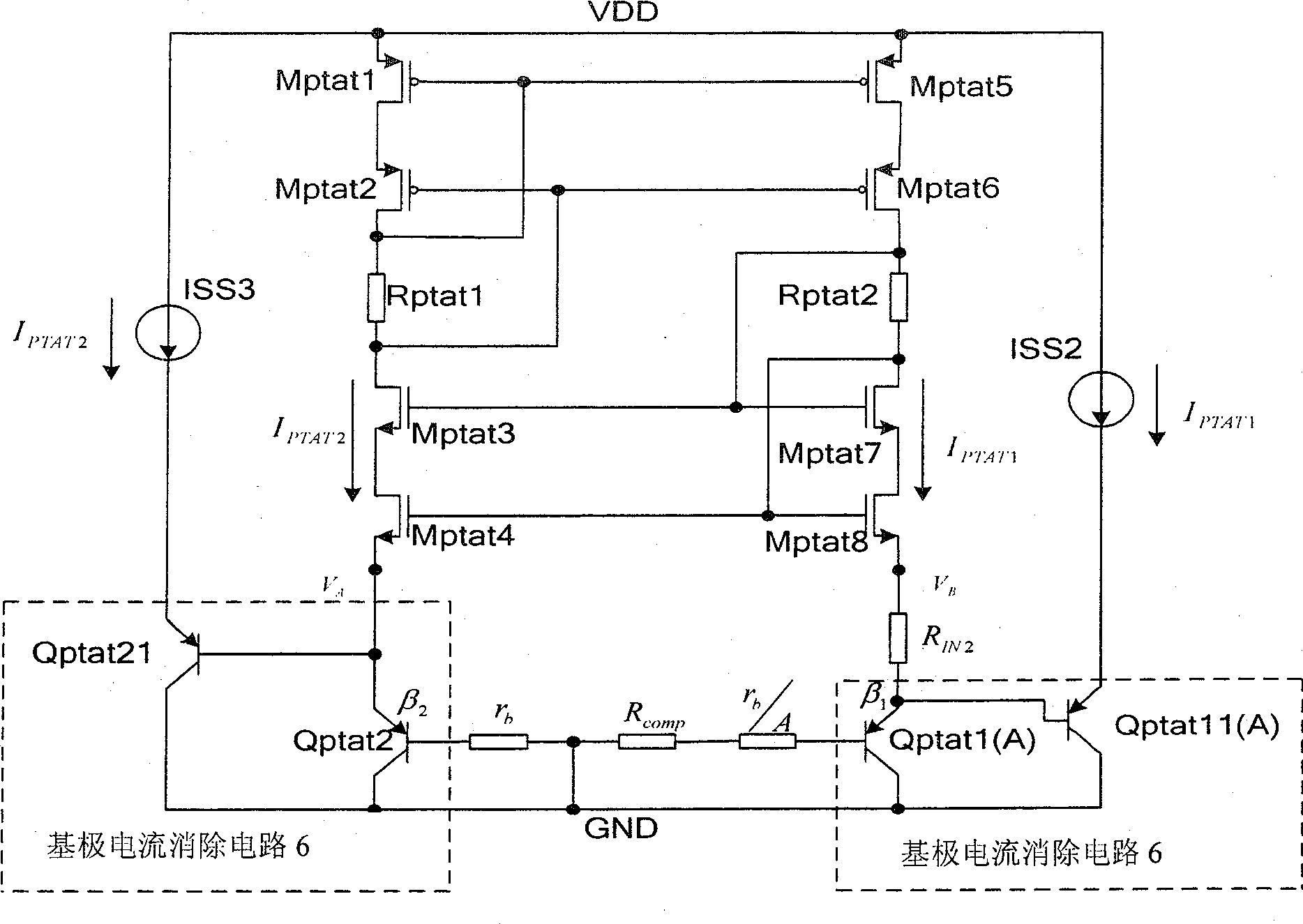

[0035] Such as figure 1 As shown, a reference voltage module of the present invention includes a current Generating circuit 1, current I PTAT Generating circuit 2, high order current I NL A generating circuit 3 , a current-type output differential reference voltage circuit 4 and a self-starting circuit 5 . electric current With figure 2 In the parasitic triode Qbe1 base-emitter voltage is proportional to the current; current I PTAT is the current proportional to the absolute temperature. electric current and by its proportionality factor K 3 Product current Divided into two inputs to the high-order current I NL Generating circuit 3, current I PTAT and by its proportionality factor K 1 The product of the current K 1 I PTAT Divided into two inputs to the high-order current I NL Generating circuit 3, high order current I NL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com