Preparation process of titania hydrosol having anatase type

A titanium dioxide and anatase type technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of difficult washing impurities, restricting industrial applications, and limiting applications, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

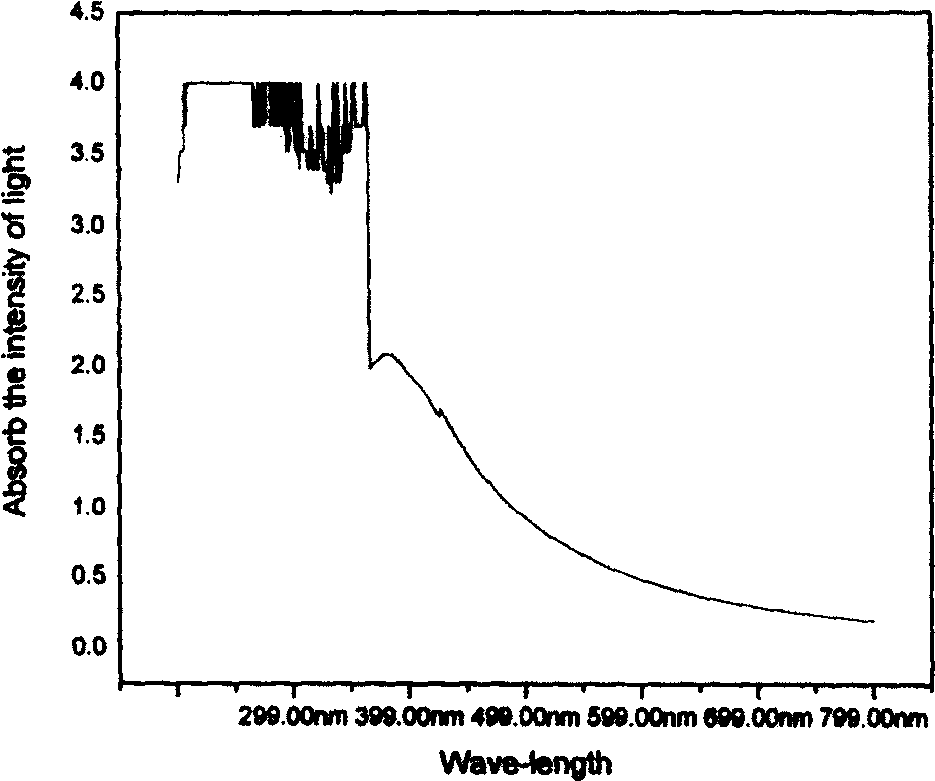

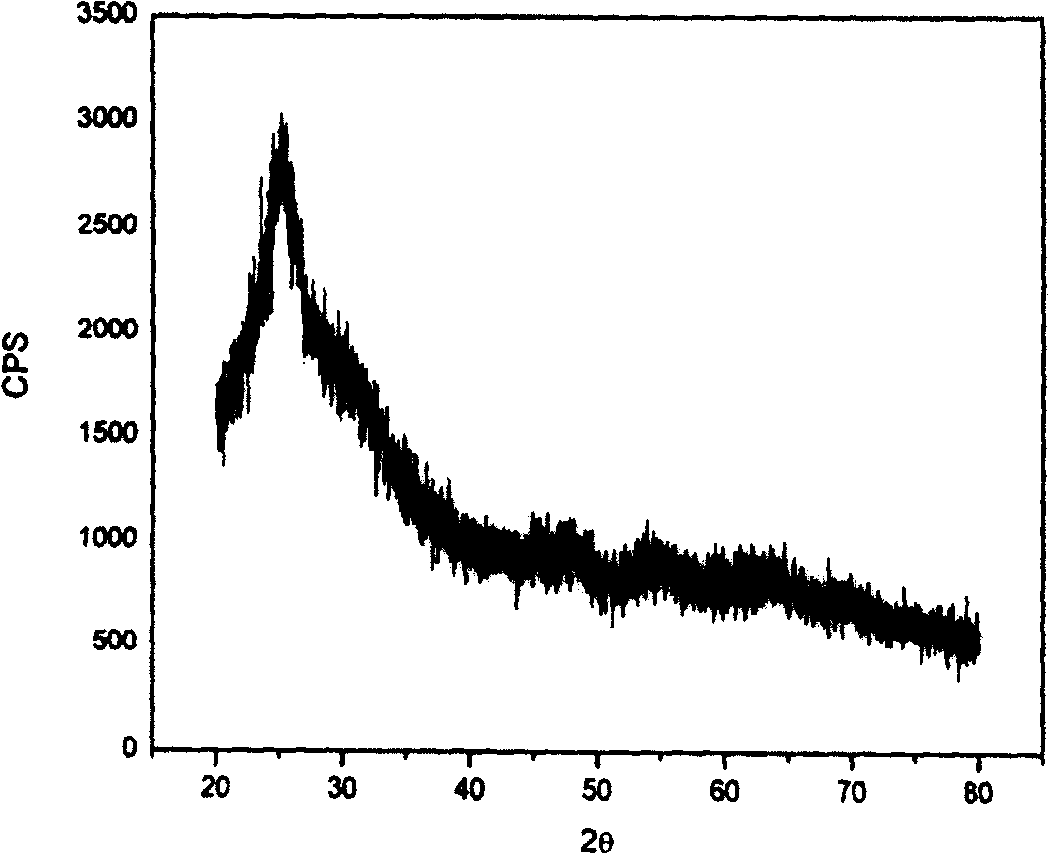

Embodiment 1

[0015] Example 1: Put 112 mL of analytically pure titanium tetrachloride solution into a three-necked flask, add 388 mL of distilled water dropwise in an ice bath, and the temperature does not exceed 20°C. A stock solution of titanium dioxide (solution I) with a concentration of about 2 mol / L was obtained. Take 20mL of solution I and add 140ml of distilled water, and hydrolyze at a constant temperature of 40°C for 5 hours. A clear solution was obtained. The extraction system using trioctylamine as the extractant and toluene as the diluent (volume ratio: 2:1) was shaken at room temperature to extract the hydrolyzed transparent solution for 15 minutes. The aqueous phase and the organic phase were separated, and the organic phase was back-extracted with 20 mL of 10% sodium hydroxide at room temperature with shaking, and the obtained organic phase could be used repeatedly. Until the pH value of the aqueous phase is 6-7. The aqueous phase is a titanium dioxide hydrosol with anat...

Embodiment 2

[0016] Example 2: Add 140ml of distilled water to 20mL of the solution I in Example 1, and perform constant temperature hydrolysis at 70°C for 1.5 hours to obtain a transparent solution. A mixed system of toluene and trioctylamine (volume ratio: 2:1) was used as the extractant to shake and extract the transparent solution after hydrolysis at room temperature for 15 minutes. The aqueous phase and the organic phase are separated, and the organic phase is reverse-extracted with 20 mL of 10% sodium hydroxide at room temperature for 3 to 5 times, and the obtained organic phase can be used repeatedly. Until the pH value of the aqueous phase is 6.5-7. The aqueous phase is a titanium dioxide hydrosol with anatase characteristics, and the sol TiO 2 The weight percentage is 2%, pH=6~7. Cl - content is 1×10 -6 ~1×10 -7 mol.L -1 .

Embodiment 3

[0017] Example 3: 20 mL of the solution I in Example 1 was added to 56 ml of distilled water, and hydrolyzed at a constant temperature of 70° C. for 1 hour to obtain a transparent solution. A mixed system of toluene and trioctylamine (volume ratio: 2:1) was used as the extractant to shake and extract the transparent solution after hydrolysis at room temperature for 15 minutes. The aqueous phase and the organic phase are separated, and the organic phase is reverse-extracted with 20 mL of 10% sodium hydroxide at room temperature for 3 to 5 times, and the obtained organic phase can be used repeatedly. Until the pH value of the aqueous phase is 6.5-7. The aqueous phase is titanium dioxide hydrosol with anatase characteristics. The sol TiO 2 The weight percentage is 5%, pH=6~7. Cl - content is 1×10 -6 ~1×10 -7 mol.L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap