Insulation material for medium voltage rubber insulation cable

A technology for insulating cables and insulating materials, which can be applied to insulators, circuits, electrical components, etc., and can solve problems such as inability to prepare high-flexible medium-voltage cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

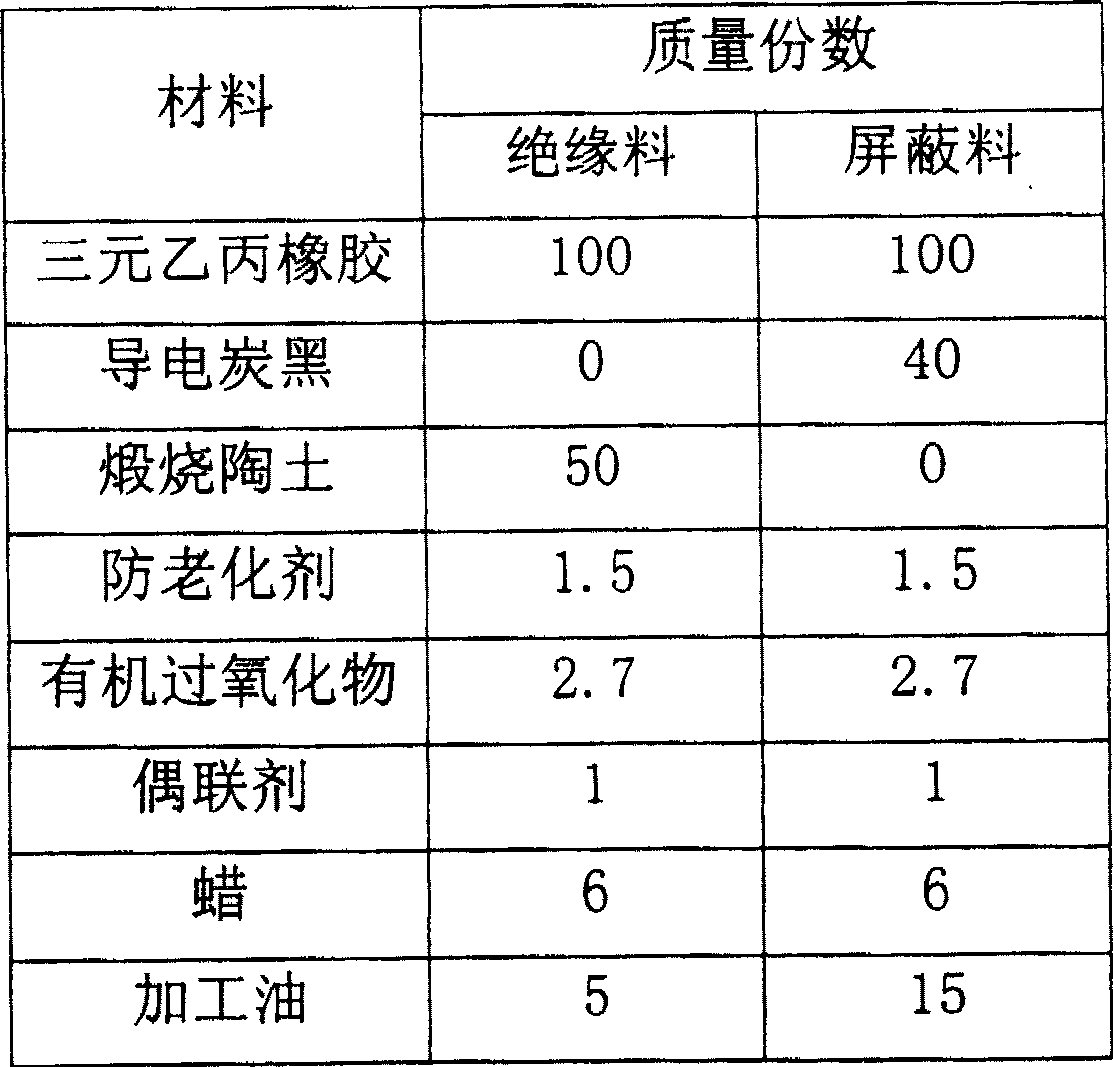

[0013] Embodiment 1: The raw material components of insulating material and shielding material are as follows:

[0014]

[0015] Among them, EPDM is a product of the Dutch National Mining Company (DSM), and the brand name is Keltan 2470. The conductive carbon black is VXC-72 produced by Cabot Corporation (CABOT). The calcined clay is Translink 37, a calcined and surface-treated clay produced by ENGELHARD. Antiaging agent is 2,2,4-trimethyl-1,2-dihydroquinoline (RD). The organic peroxide is dicumyl peroxide (DCP) and the coupling agent is vinyl tris(methoxyethoxy)silane (A-172). The wax is paraffin. The processing oil was SUNPAR 2280 produced by Sunoco.

[0016] The preparation method is as follows: first put EPDM rubber and anti-aging agent into the banbury mixer, after banburying for 3 minutes, add calcined clay (insulating material) or conductive carbon black (shielding material), then add wax and processing oil, continue banburying for 2 minutes, then add Coupling a...

Embodiment 2

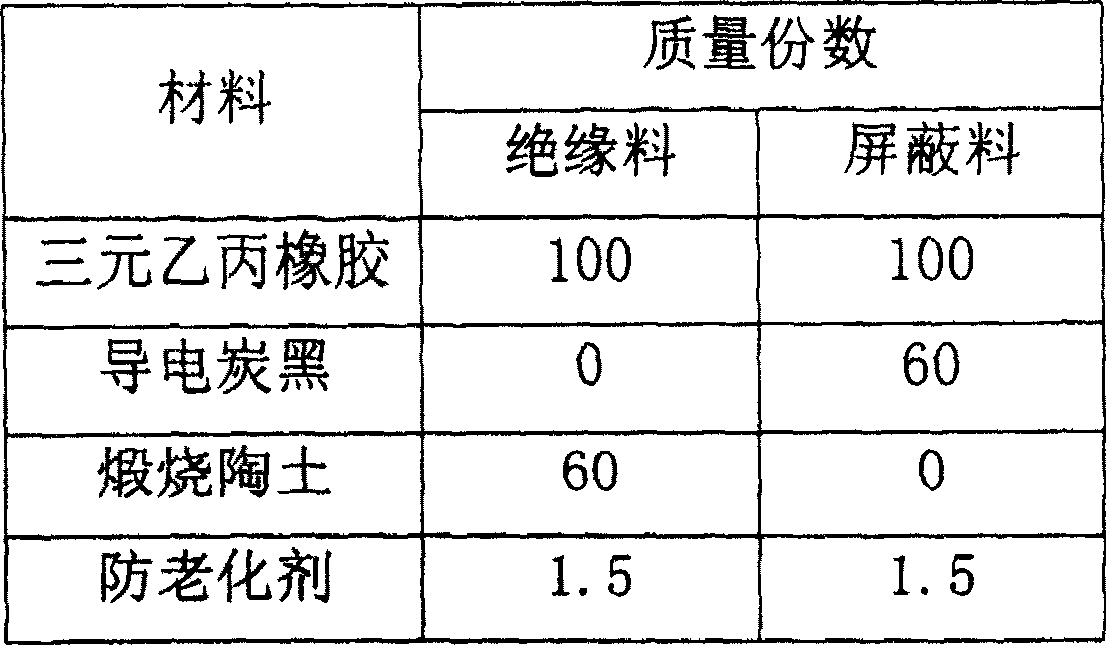

[0019] Embodiment 2: insulating material and shielding material raw material components are as follows:

[0020]

[0021]

[0022] Among them, EPDM is the product of JSR Company, and the grade is EP21. The conductive carbon black is BP2000 produced by Cabot Corporation (CABOT). The calcined clay is Translink 77, a calcined and surface-treated clay produced by ENGELHARD. Antiaging agent is 1,2-mercaptobenzimidazole (MB). The organic peroxide is dicumyl peroxide (DCP). The coupling agent is vinyltrimethoxysilane (A-171). The wax is polyethylene wax. The processing oil was SUNPAR 2280 produced by Sunoco.

[0023] The preparation method is as follows: first put EPDM rubber and anti-aging agent into the two-roller open mill, add calcined clay (insulation material) or conductive carbon black (shielding material) after wrapping the rolls, then add wax and processing oil, after the powder is finished, Add coupling agent, then add organic peroxide, thin pass 8 times, then r...

Embodiment 3

[0026] Embodiment 3: insulating material and shielding material raw material components are as follows:

[0027]

[0028]

[0029] Among them, EPDM is the product of ExxonMobil Company, and the brand name is Vistalon 1703P. Conductive carbon black is N220 from Tianjin Carbon Black Factory. Calcined clay is domestic calcined and surface treated clay Glc. Antiaging agent is 1,2-mercaptobenzimidazole (MB). The organic peroxide is dicumyl peroxide (DCP) and the coupling agent is vinyl tris(methoxyethoxy)silane (A-172). The wax is paraffin. The processing oil was SUNPAR 2280 produced by Sunoco.

[0030] The preparation method is as follows: the formula components are assembled in corresponding hoppers, and the continuous mixing twin-screw granulator is used for dispersing and granulating.

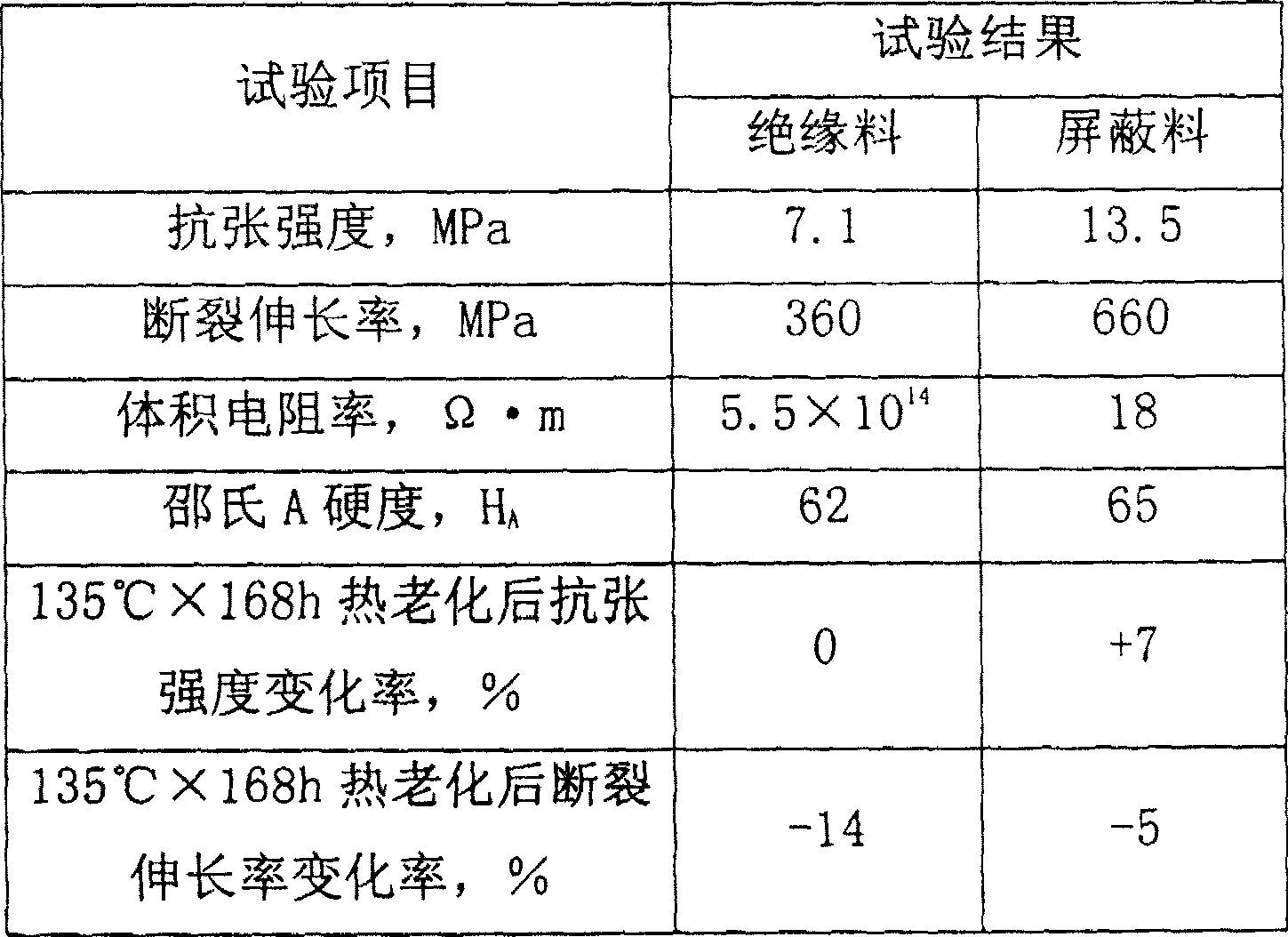

[0031] After pressing the processed insulating material and shielding material into a test piece, after heat vulcanization at 160℃×40min, the performance is measured as follows:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com