Optical catalytic hydrogen production system by directly utilizing solar energy to decompose water

A hydrogen production system and solar energy technology, applied in the directions of hydrogen production, energy input, etc., can solve problems such as the inability to directly and effectively utilize solar energy, and achieve the effects of simple structure, strong adaptability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

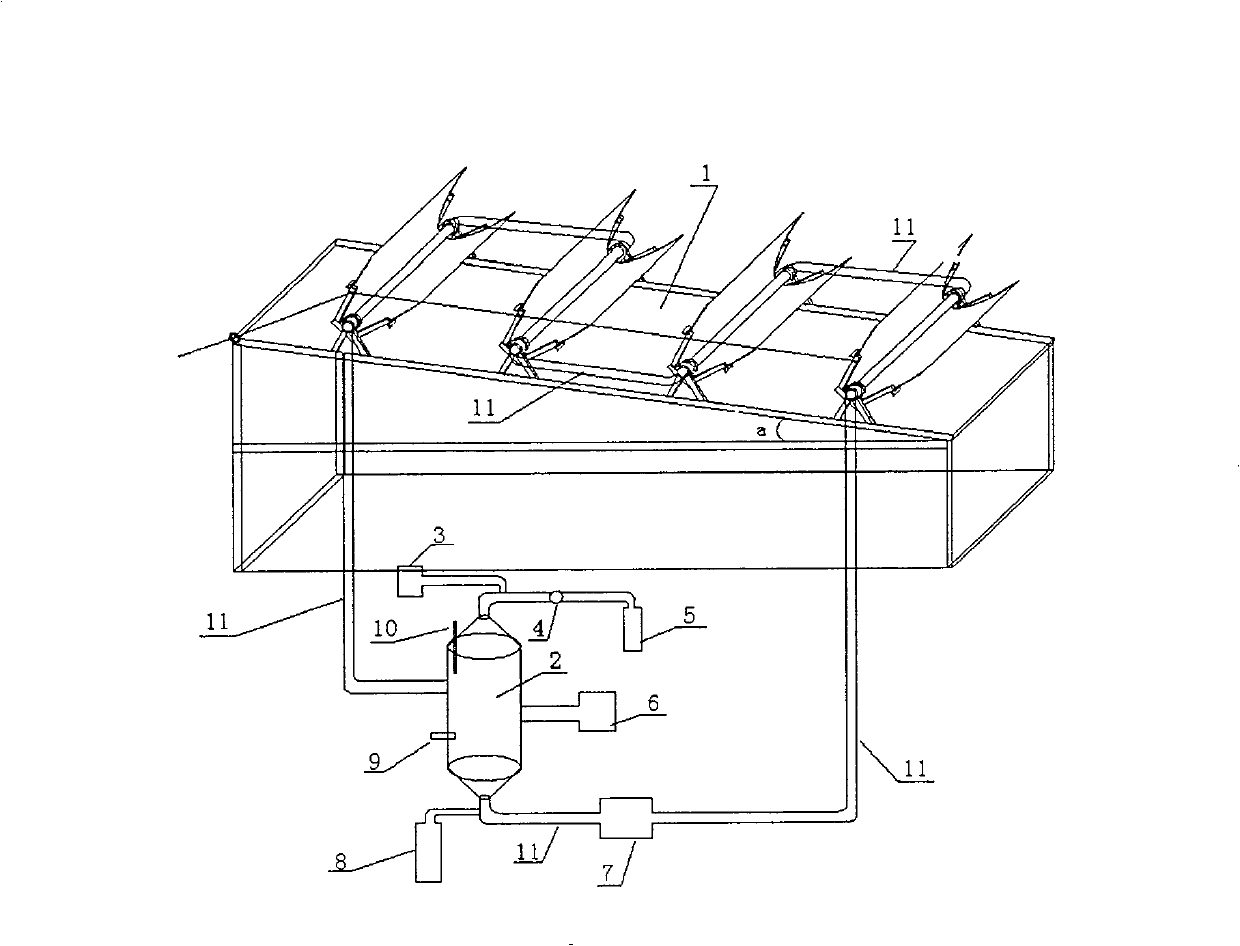

[0023] Such as figure 1 As shown, the feed port of the liquid storage tank 2 is connected with a feed pump 6, and the top outlet of the liquid storage tank 2 is connected to the gas chromatograph 3, the flow meter 4 and the gas collecting bottle 5 in turn; the bottom outlet is connected to the circulation pump 7, and the circulation pump 7 is connected to one end of the photocatalytic reactor 1, and the other end of the photocatalytic reactor 1 is connected to the liquid storage tank 2; a temperature probe 9 and a precision pressure gauge 10 are arranged on the wall of the liquid storage tank 2. The above components are connected by vacuum glass valves, PVC pipes 11 and silicone tubes to form the reaction part, circulation part, monitoring part and feeding and discharging parts of the device.

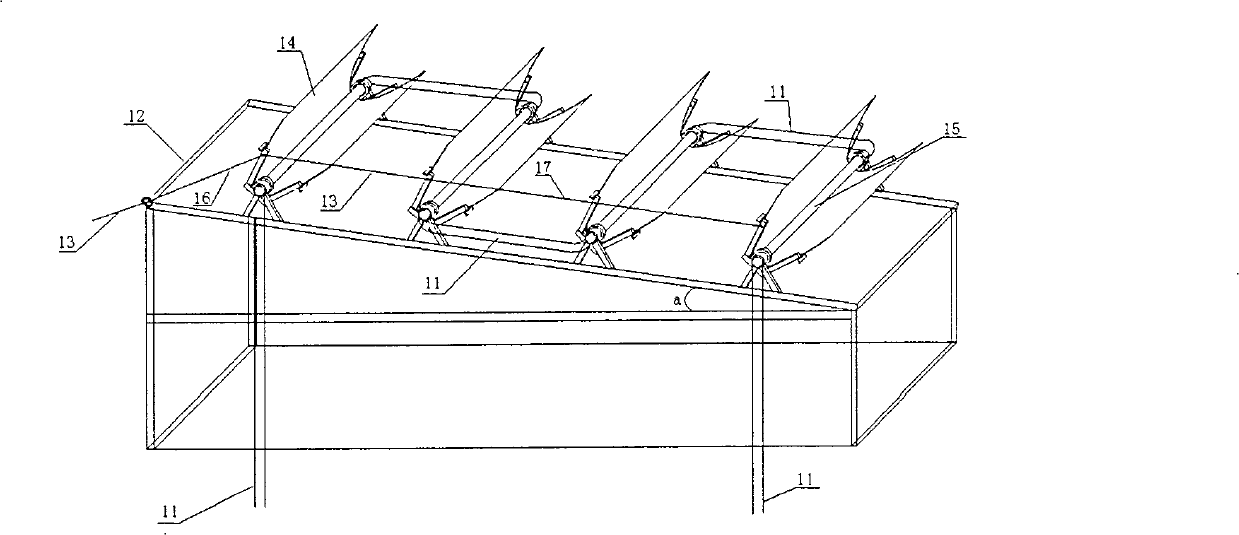

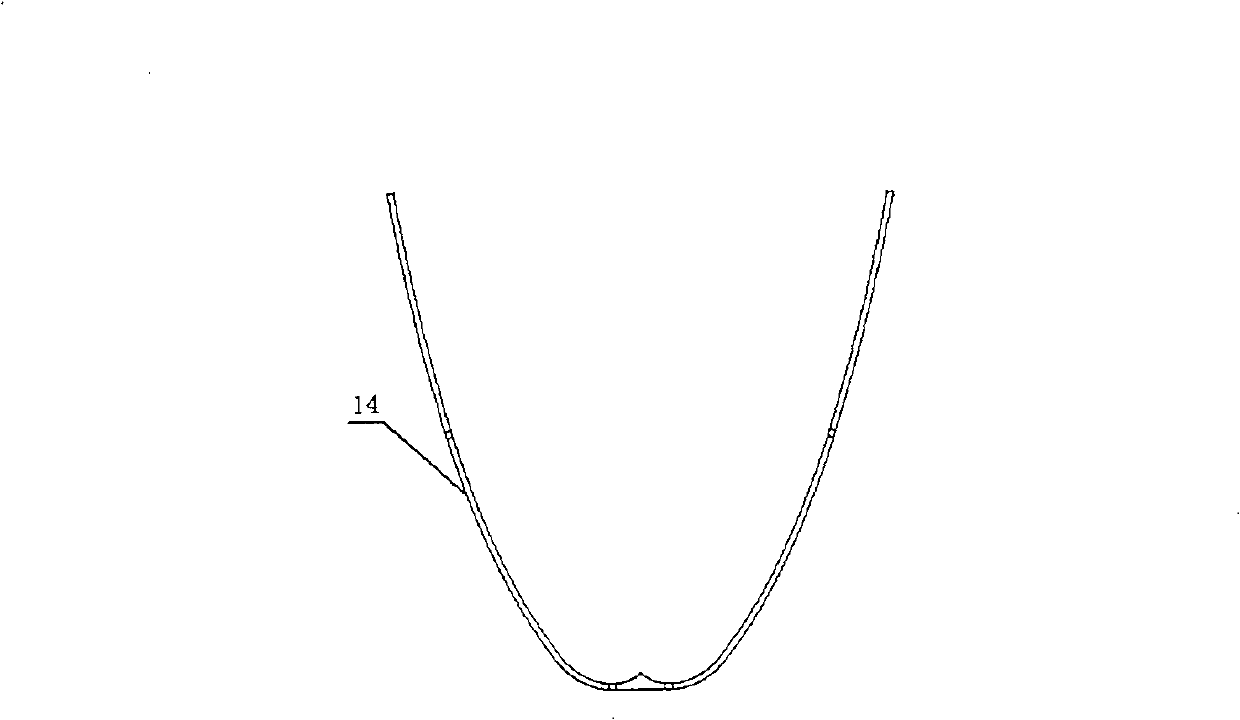

[0024] Reaction part: composed of photocatalytic reactor 1, the photocatalytic reaction is carried out in the tubular reactor 15, when the reaction liquid flows through the tubular reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com