Vacuum heat-insulating material and manufacturing method thereof

A technology of vacuum thermal insulation material and manufacturing method, which is applied in chemical instruments and methods, heat exchange equipment, and pipeline protection through thermal insulation, etc. Portability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

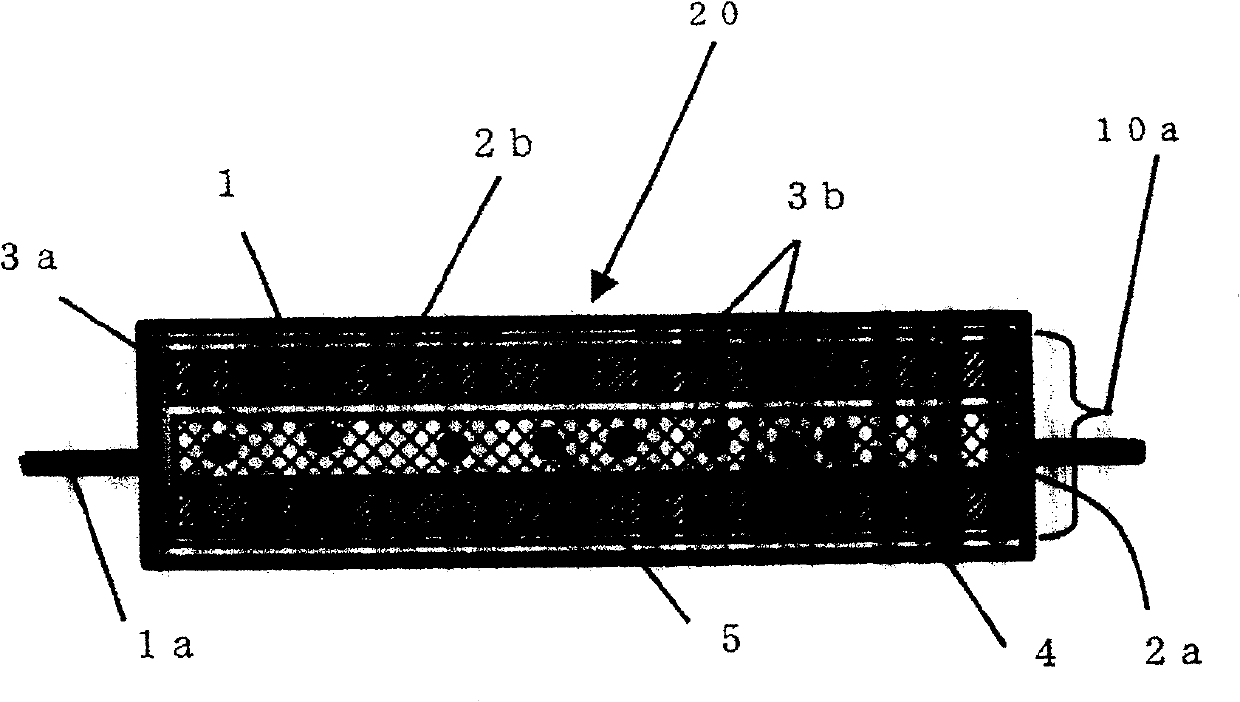

[0039] use figure 1 ˜ FIG. 5 illustrate the vacuum heat insulating material and its manufacturing method according to the first embodiment of the present invention. First, refer to figure 1 The structure of the vacuum heat insulating material 20 according to this embodiment will be described simultaneously. figure 1 It is a cross-sectional view of the vacuum insulation material 20 according to the first embodiment of the present invention.

[0040] The vacuum heat insulating material 20 includes a core material 10a, and an airtight outer covering material 1 that stores the core material 10a, depressurizes the inside, welds the peripheral portion and seals it. The vacuum heat insulating material is constituted by a flat rectangular plate.

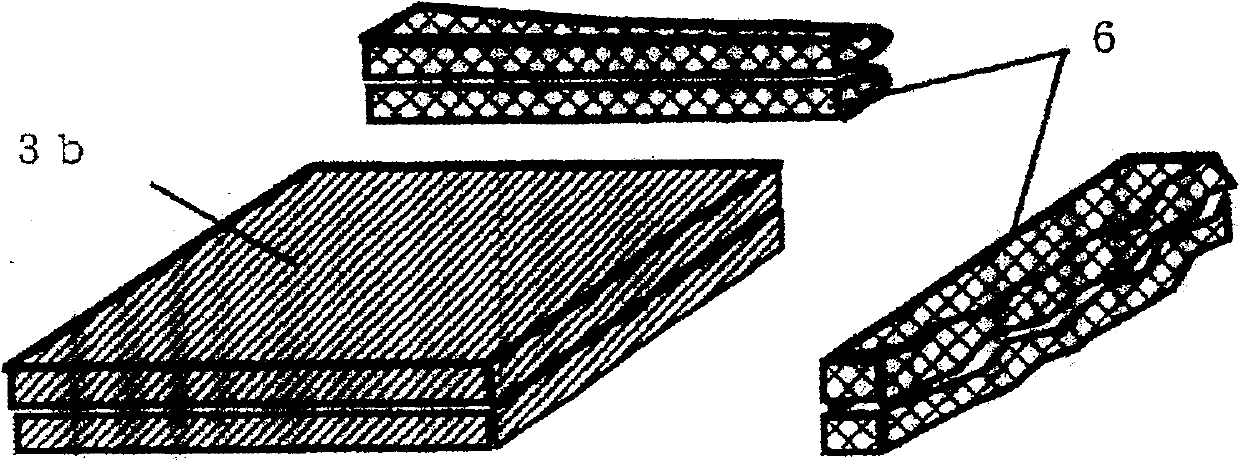

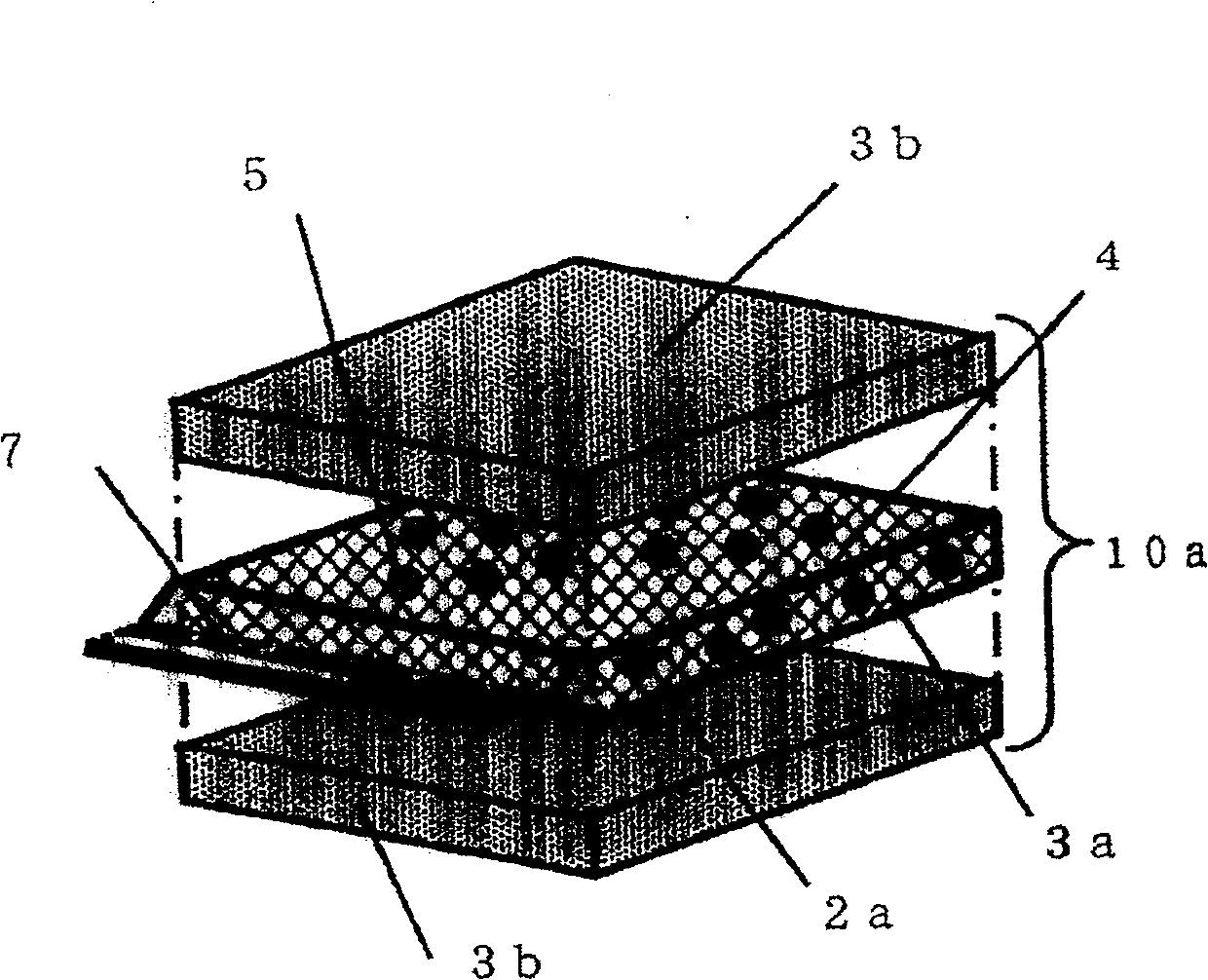

[0041] This core material 10a is a laminated body in which a plurality of heat insulators are stacked, and consists of a first core material (hereinafter referred to as "insulator a") 3a which is cut into a plurality to make the laminated...

no. 2 approach

[0075] The heat insulator a3a is provided on at least one side to maintain the shape, and the heat insulator a3a is wrapped with the inner covering material a2a to spread the inorganic fiber aggregates of a plurality of cut off pieces 4 so as to make the laminate into a required size. The core material 10b is formed as follows: it is composed of a laminated body in which the ratio of the thermal insulator a3a relative to the whole is 50% by weight, and the thermal insulator b3b composed of an inorganic fiber aggregate not containing a binder, together with the inner covering material b2b Both sides are covered to form the core material 10b.

[0076] Regarding this second embodiment, using Figure 8 Be explained. Figure 8 It is a perspective view of the core material 10b assembled and used in the vacuum heat insulating material 20 of 2nd Embodiment of this invention. This second embodiment is different from the first embodiment in the points described next, and since the oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com