Method for measuring rotor bow with transverse currents sensing method

A technology of rotor bending and eddy current sensor, applied in measuring device, point coordinate measurement, electromagnetic measuring device, etc., can solve the problems of easy error, complicated operation, low efficiency, etc., to achieve convenient operation, overcome complex operation, and high accuracy Effect

Inactive Publication Date: 2009-08-05

SOUTHEAST UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] This measurement method is complicated to operate; manual reading is required, which is prone to errors; bending curves need to be drawn manually; the most important thing is that it takes a long time and the efficiency is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0036] The present invention has been run on a test bench and has achieved good results. This test uses the TX-3 vibration simulation rotor test bench, which is used to simulate the rotor whose upper end cover has been uncovered and is still placed in the cylinder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

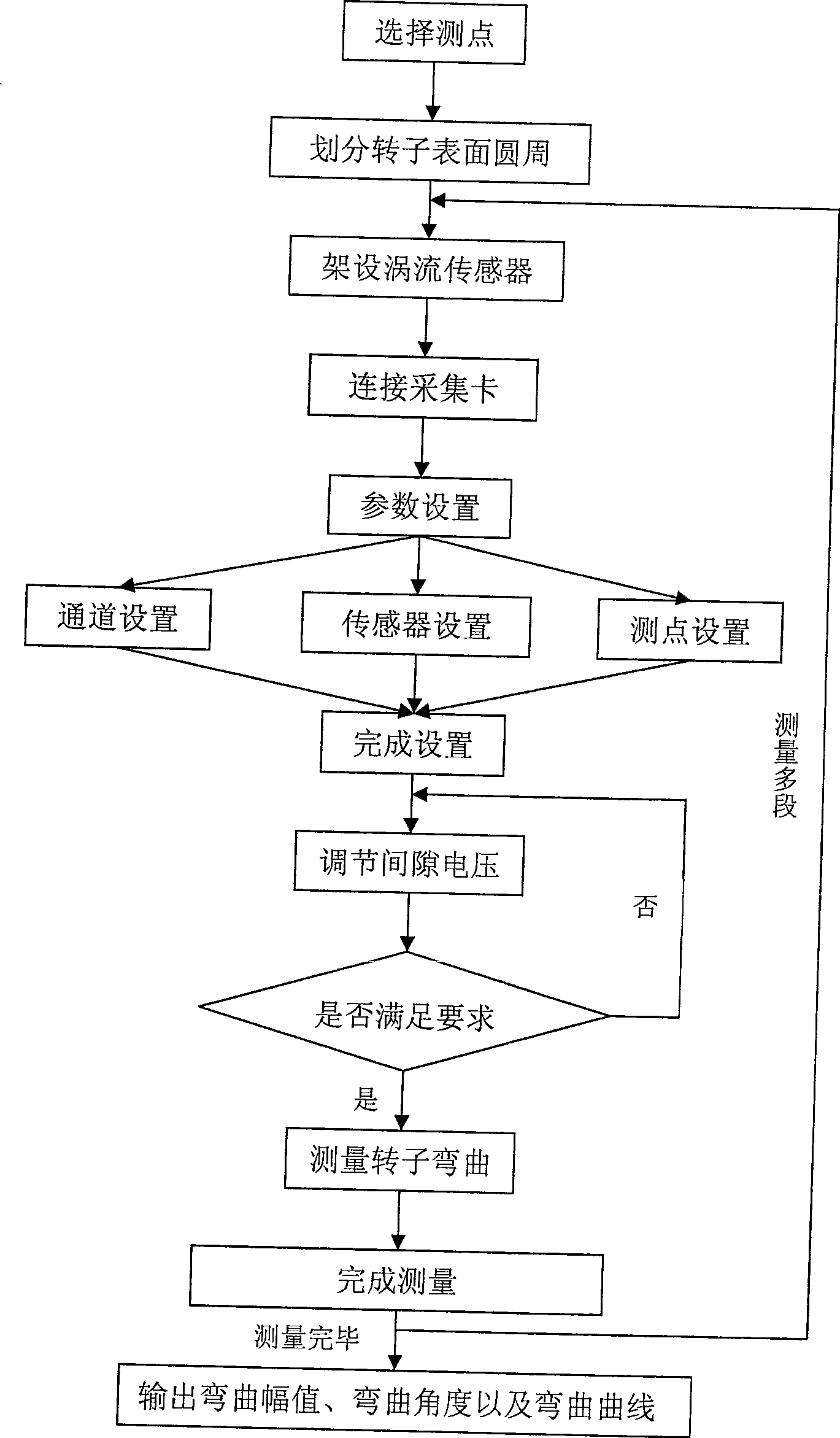

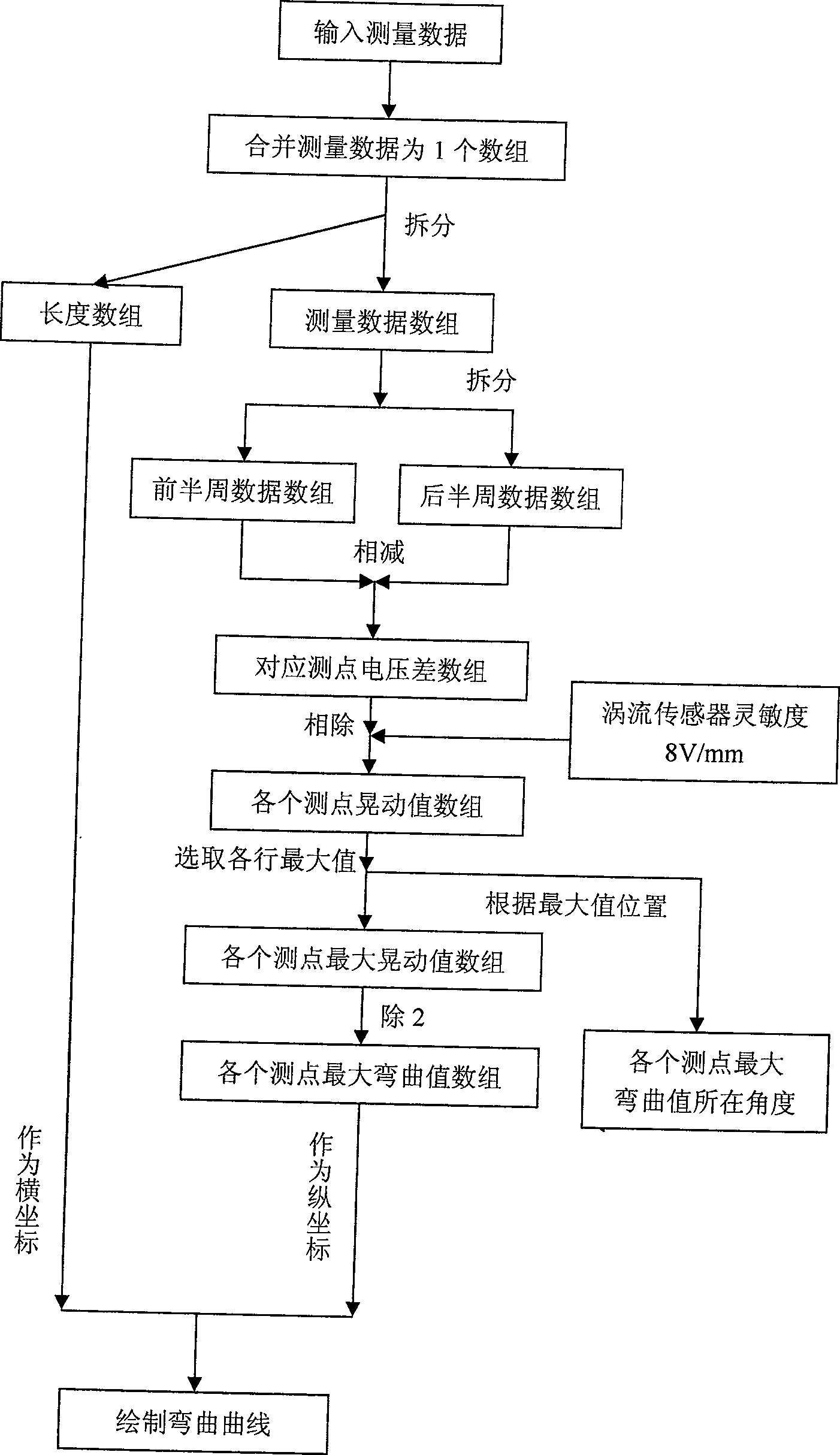

The invention relates to an eddy transducer rotor curve contactless measuring method mainly used for the measurement and curves drawing of a rotor of large rotary machinery. Signals collected by an eddy transducer are input into a computer through an acquisition card and processed on virtual instrument LabVIEW software platform. Curve characteristics and the curves of the rotor are output. Compared with the existing measuring method, the advantages of the measuring method are embodied in the operational convenience. The system adopts the eddy transducer instead of dial indicators in existing system as data-collecting front-end in order to overcome the disadvantages of operational complexity of existing measuring method. Both the fixation and the reading of dial indicators used for being arranged in gaps between the rotor blades are not convenient. By adopting the eddy transducer, the only thing necessary is to adjust and fix the gap voltage, and the eddy transducers is non-contact measurement, only the gap between the front-end of the eddy transducer and rotor surface needs to be adjusted, which is convenient for operation.

Description

technical field [0001] The invention is mainly used for the measurement and bending curve drawing of large rotating machine rotors, especially for the measurement and bending curve drawing of steam turbine rotors of generator sets. Background technique [0002] Measuring principle: measure the maximum bending amount of each point in the length direction of the rotor, and draw a bending curve with the length of the rotor as the abscissa and the maximum bending amount of each point as the ordinate. [0003] Wobble - The radial runout of the outer edge of a rotating part relative to the axis. [0004] Bending—the deviation between the line connecting the maximum radial runout points on each section of the shaft and the original axis. [0005] The maximum bend value is one-half the value of the maximum shake. [0006] The current measurement method: the rotor bending measurement mostly adopts the mechanical diameter measurement in the contact measurement method. The measureme...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B7/00G01B7/004G01B7/30G01B7/31

Inventor 杨为民杨建刚张磊

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com