A pH-sensitive fe3o4@ldh-loaded nano drug particle of methotrexate, its preparation method and its application

A technology of methotrexate and nano-drugs, which is applied in the direction of drug combinations, pharmaceutical formulas, and medical preparations of non-active ingredients, etc. It can solve the problems of poor actual targeting performance, inability to effectively act on lesion sites, lack of identification of lesion sites, etc. problems, to achieve the effect of improving efficacy and bioavailability, increasing drug loading, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

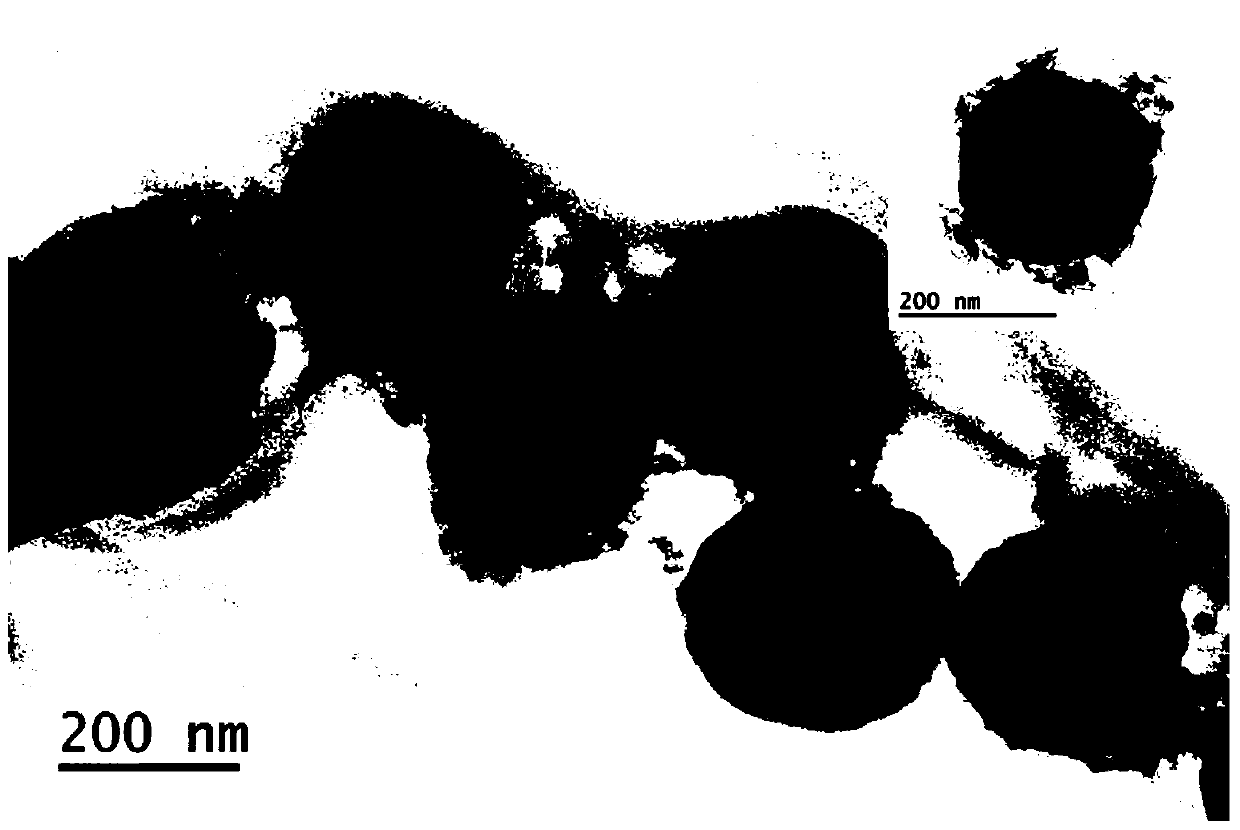

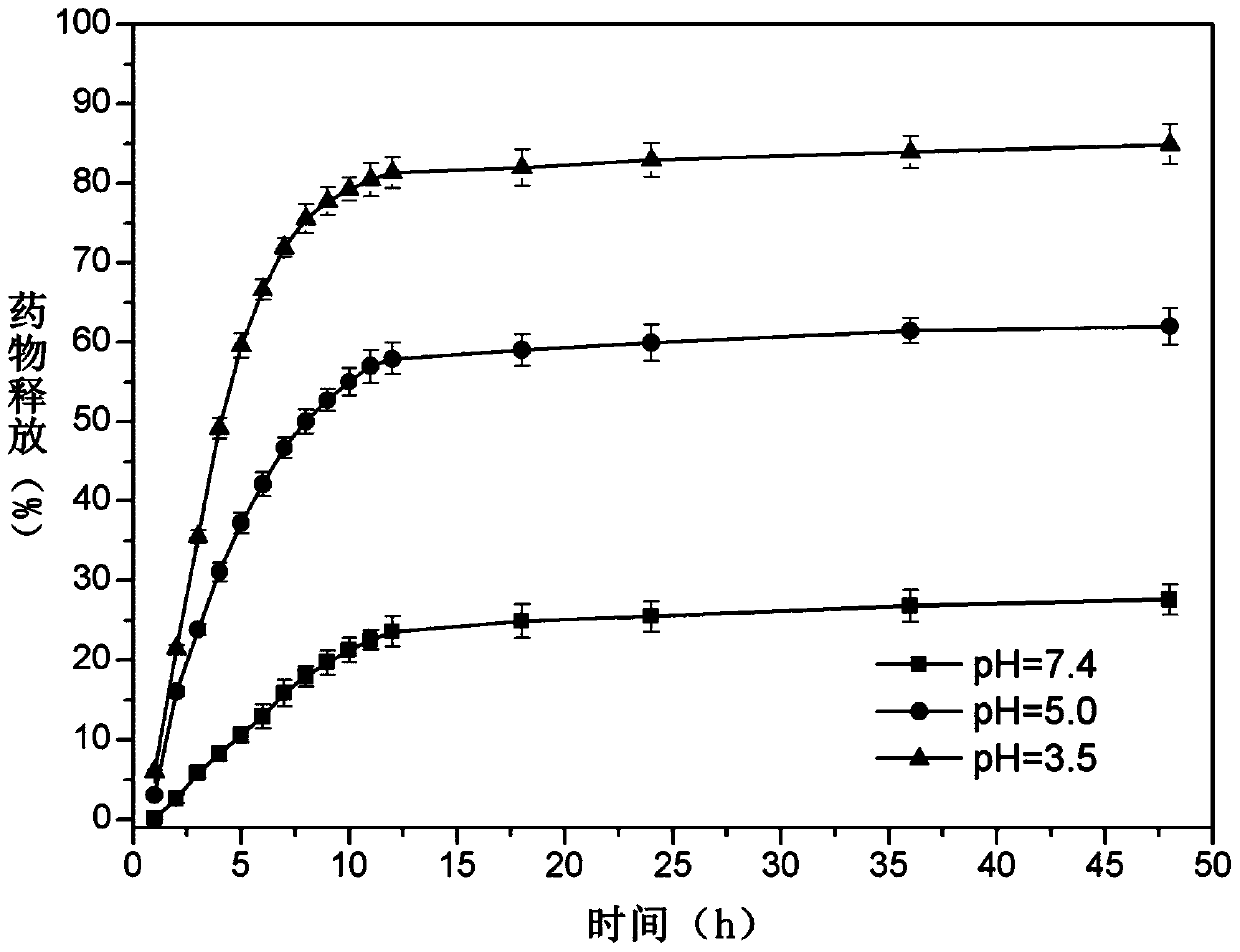

[0031] Example 1: Fe 3 o 4 Preparation of @LDH-MTX

[0032] Sequentially weigh 0.5g FeCl 3 ·6H 2 O, 3.0g sodium acetate, dissolved in 40mL ethylene glycol, ultrasonically stirred for 20min to disperse the system evenly, then added 2.0g LDH to the mixed solution, continued ultrasonically stirred for 10min, then transferred the uniform mixed solution into polytetrafluoroethylene In the reaction kettle, react at 200°C for 10h. After the reaction was completed, the product was poured out, extracted by magnetic decantation, and washed several times with deionized water. The washed product was dried in a vacuum oven at 25°C to obtain dry powdered Fe 3 o 4 @LDH Carrier.

[0033] Sequentially weigh 50 mg of dry Fe 3 o 4 @LDH, 2.5mg MTX, dissolved in 20mL deionized water, ultrasonicated for 5min to disperse the system evenly. Then transfer to a one-necked flask, and react in the dark at 55°C for 3 days.

[0034]After the reaction was completed, the product was poured out, ex...

Embodiment 2

[0037] Example 2: Fe 3 o 4 Preparation of @LDH-MTX

[0038] Sequentially weigh 0.5g FeCl 3 ·6H 2 O. Dissolve 3.0g of sodium acetate in 40mL of ethylene glycol, stir ultrasonically for 20min to disperse the system evenly, then add 2.0g LDH to the mixture, and continue ultrasonically stirring for 10min. Afterwards, the homogeneous mixed liquid was transferred into a polytetrafluoroethylene reactor and reacted at 200°C for 8 hours. After the reaction was completed, the product was poured out, extracted by magnetic decantation, and washed several times with deionized water. Then, the product was dried in a vacuum oven at 25°C to obtain dry powdered Fe 3 o 4 @LDH Carrier.

[0039] Sequentially weigh 50 mg of dry Fe 3 o 4 @LDH, 3mg MTX, dissolved in 20mL deionized water, ultrasonicated for 5min to disperse the system evenly. Then transfer to a one-necked flask, and react in the dark at 55°C for 3 days.

[0040] After the reaction was completed, the product was poured out,...

Embodiment 3

[0041] Example 3: Fe 3 o 4 Preparation of @LDH-MTX

[0042] Sequentially weigh 0.5g FeCl 3 ·6H 2 O. Dissolve 3.0g of sodium acetate in 40mL of ethylene glycol, and stir ultrasonically for 20min to disperse the system evenly. Then, 2.0 g LDH was added to the mixture, and ultrasonic stirring was continued for 10 min. Afterwards, the homogeneous mixed liquid was transferred into a polytetrafluoroethylene reactor, and reacted at 190° C. for 10 h. After the reaction was completed, the product was poured out, extracted by magnetic decantation, and washed several times with deionized water. Then, the product was dried in a vacuum oven at 30°C to obtain dry powdered Fe 3 o 4 @LDH Carrier.

[0043] Sequentially weigh 50 mg of dry Fe 3 o 4 @LDH, 5mg MTX, dissolved in 20mL deionized water, ultrasonic 5min to make the system evenly dispersed. Afterwards, it was transferred to a one-necked flask, and reacted in the dark at 65° C. for 3 days.

[0044] After the reaction was comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com