Device and method for preparation of lithium nickel manganese cobaltate by hot cyclonic mechanochemical coating process

A technology for preparing nickel manganese cobalt oxide and mechanochemical technology, applied in the field of energy materials, can solve the problems of manufacturing of speed-increasing mechanical transmission parts, difficulty of axial mechanical sealing, small loading of materials, etc., and achieve controllable coating amount. , to avoid safety problems, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

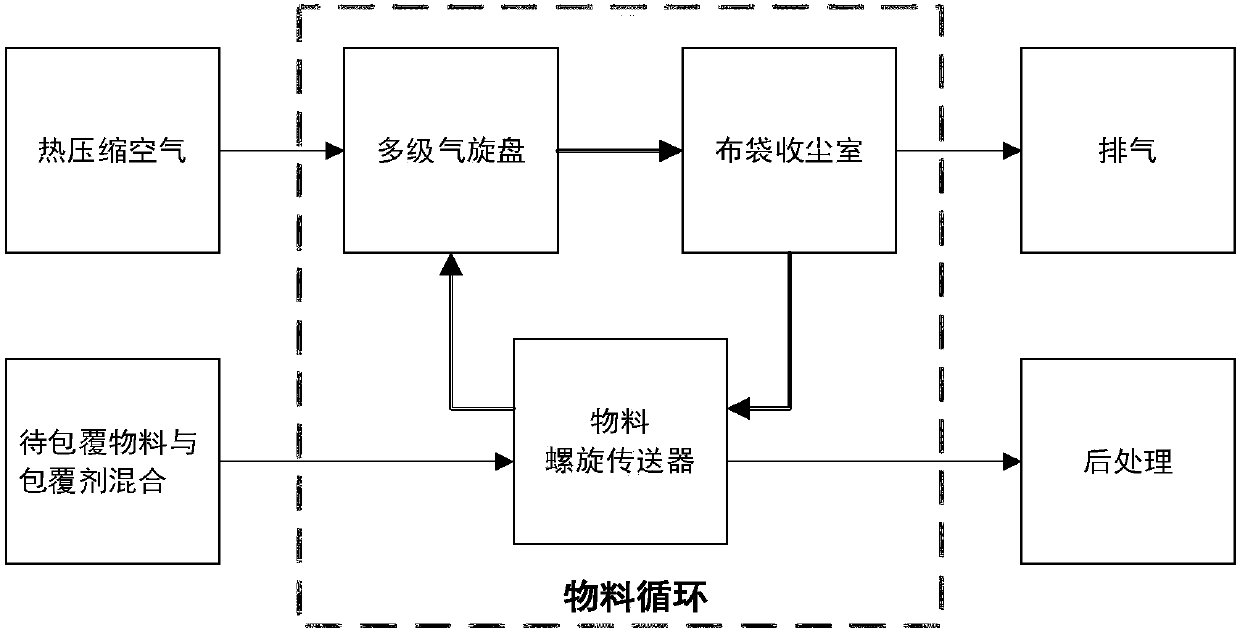

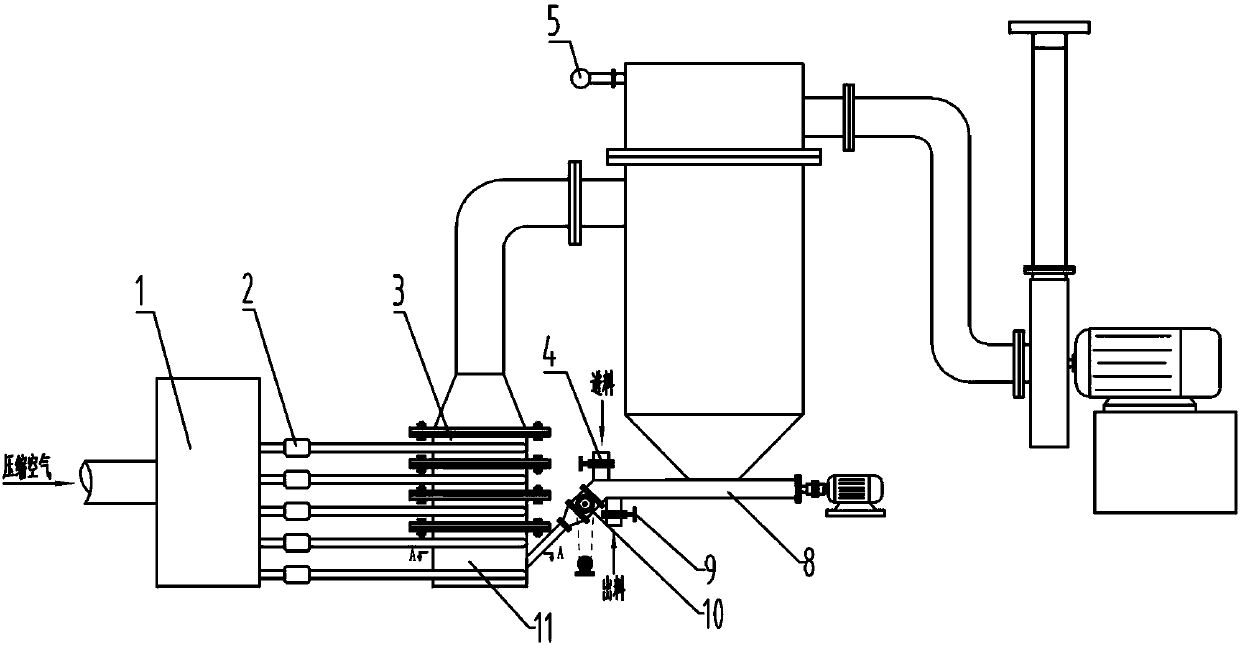

[0041] use figure 2 and image 3 The device for preparing lithium nickel manganese cobalt oxide material by hot cyclone mechanochemical coating method is shown. The device includes

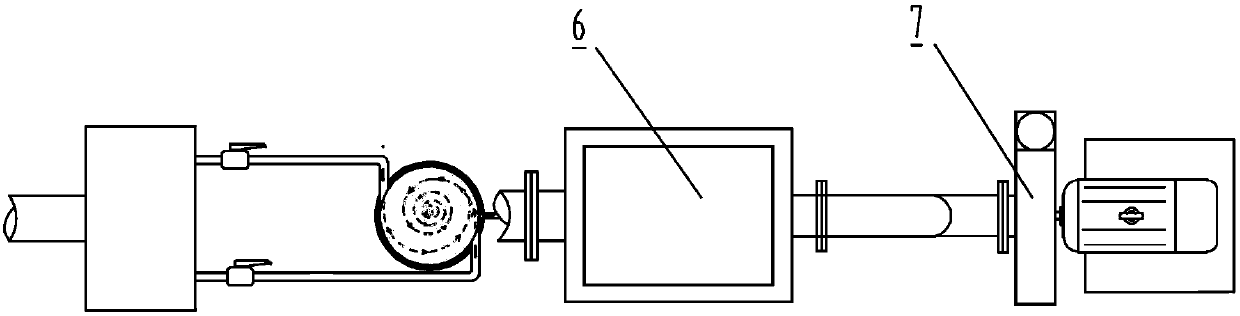

[0042] Compressed air heating chamber 1, multi-stage cyclone disk 3, bag dust collection chamber 6, screw conveyor. The output pipeline of the compressed air heating chamber 1 is connected to the multi-stage cyclone disc 3; the top of the multi-stage cyclone disc 3 is connected to the baghouse 6 through the pipeline, and the bottom of the baghouse 6 is connected to the multi-stage cyclone 3 through the screw conveyor The bottom of the bottom forms a material circulation loop; the baghouse 6 is connected to an exhaust fan; the screw conveyor is provided with a material feeding device and a discharge pipe.

[0043] In this embodiment, the compressed air heating chamber 1 adopts a labyrinth resistance heating box with a power of 60kW. 3 / min of high-pressure air is heated to 300-400°C; air press...

Embodiment 2

[0052] Nickel manganese cobalt hydroxide is prepared by co-precipitation method under the protection of inert atmosphere by using nickel manganese cobalt sulfate mixed solution as raw material and sodium hydroxide solution as precipitant, wherein the atomic ratio of Ni:Mn:Co is 1:1 :1. Then roast at 800°C for 2 hours to obtain nickel-manganese-cobalt oxide, then mix it with lithium carbonate or lithium hydroxide in stoichiometric ratio, and roast at 1000°C for 6 hours to obtain lithium nickel-manganese-cobaltate material LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 (referred to as NCM111).

[0053] Take 20kg of NMC111 material and highly active nano Al 2 o 3 400g, mixed in a V-type mixer for 2h.

[0054] Adopt the device of embodiment 1, preheat the compressed air to 250~300 ℃, start the air shutoff device 10 after feeding a small amount of compressed air first; open the feeding pipe butterfly valve 4, open the delivery screw 8, mix the NMC111 and Al 2 o 3 The mixture is added through ...

Embodiment 3

[0058] Nickel manganese cobalt hydroxide is prepared by co-precipitation method under the protection of inert atmosphere with nickel manganese cobalt sulfate mixed solution as raw material and sodium hydroxide solution as precipitant, wherein Ni:Mn:Co atomic ratio is 5:3: 2. Calcined at 600°C for 6 hours to obtain nickel-manganese-cobalt oxide, then mixed with stoichiometric lithium carbonate or lithium hydroxide, and calcined at 850°C for 16 hours to obtain lithium nickel-manganese-cobaltate material LiNi 0.5 mn 0.3 co 0.2 o 2 (referred to as NCM532).

[0059] Take 20kg of NMC532 material and highly active nano TiO 2 150g, mixed in a V-type mixer for 2h.

[0060] Use the same equipment as in Example 1 and the method of Example 2 for coating treatment for 4 hours.

[0061] The cyclone-treated material was calcined for 5 hours in an oxidizing atmosphere at a temperature range of 800° C. to obtain a titanium-coated NCM532 positive electrode active material. The tap densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com