Preparation device and preparation method of nearly-spherical titanium carbide coated high-speed steel composite powder

A composite powder and preparation device technology, which is applied in transportation and packaging, gaseous chemical plating, metal processing equipment, etc., can solve the problems of shortened life, performance decline, etc. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

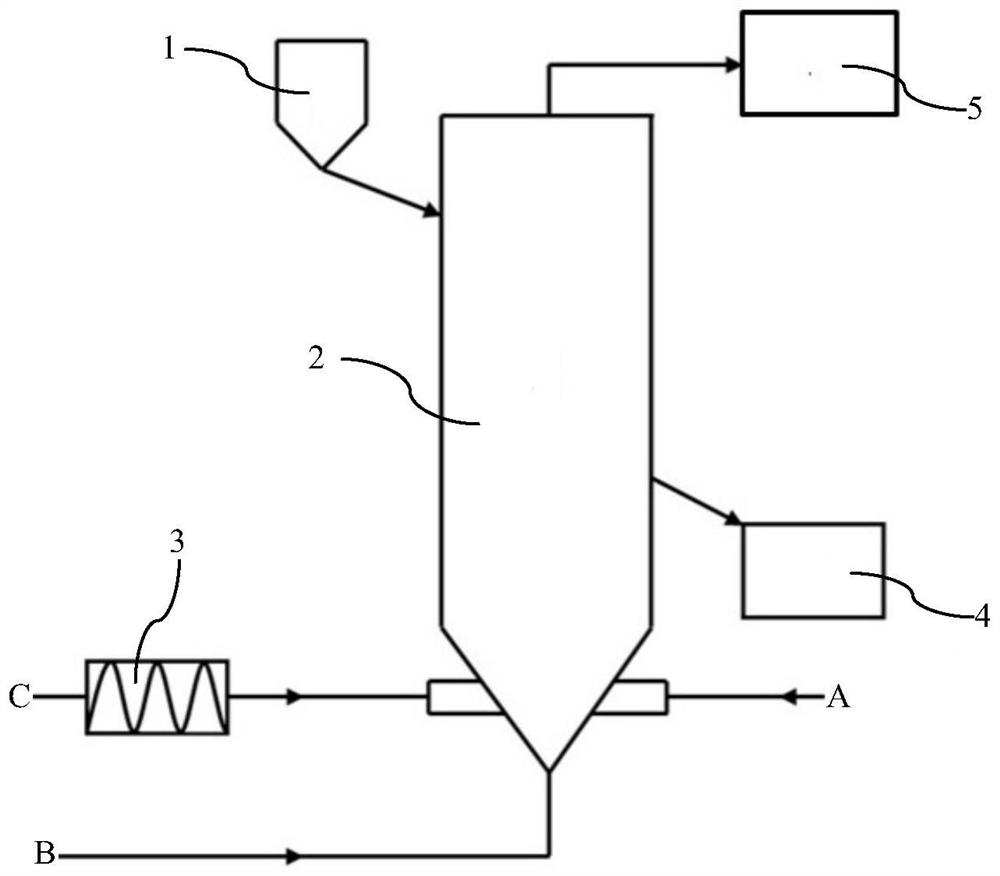

[0041] This embodiment provides a method for preparing a near-spherical titanium carbide-coated high-speed steel composite powder. figure 1 In the device system shown, the preparation method comprises the following steps:

[0042] (1) The high-speed steel powder with a particle size of 1 μm-30 μm is placed in a fluidized state in the protective atmosphere of the fluidized bed reactor.

[0043] (2) On the basis that step (1) continues to be carried out, the titanium source and the reaction gas are synchronously introduced into the fluidized bed reactor, and mixed with the high-speed steel powder at a mixing temperature of 600 ° C (in other embodiments, it can also be 500°C, 700°C, 800°C, 900°C, 950°C, 1000°C), mixing time 60min (in other embodiments, it can also be 1min, 5min, 10min, 15min, 20min, 30min, 40min, 50min, 120min), The temperature of the titanium source is 20°C, and the gas velocity is 50ml (in other embodiments, it can also be 10mL / min, 20mL / min, 30mL / min, 70mL / mi...

Embodiment 2

[0048] This embodiment provides a method for preparing a near-spherical titanium carbide-coated high-speed steel composite powder. figure 1 In the device system shown, the preparation method comprises the following steps:

[0049] (1) The high-speed steel powder with a particle size of 1 μm-30 μm is placed in a fluidized state in the protective atmosphere of the fluidized bed reactor.

[0050] (2) On the basis that step (1) continues to be carried out, the titanium source and the reaction gas are synchronously introduced into the fluidized bed reactor, mixed with the high-speed steel powder, the mixing temperature is 800 ° C, and the mixing time is 90 min. The temperature is 40°C, the gas flow rate is 75ml, and the reaction gas gas flow rate is 150ml.

[0051] (3) After the reaction is completed, gas-solid separation is obtained to obtain titanium carbide-coated high-speed steel composite powder.

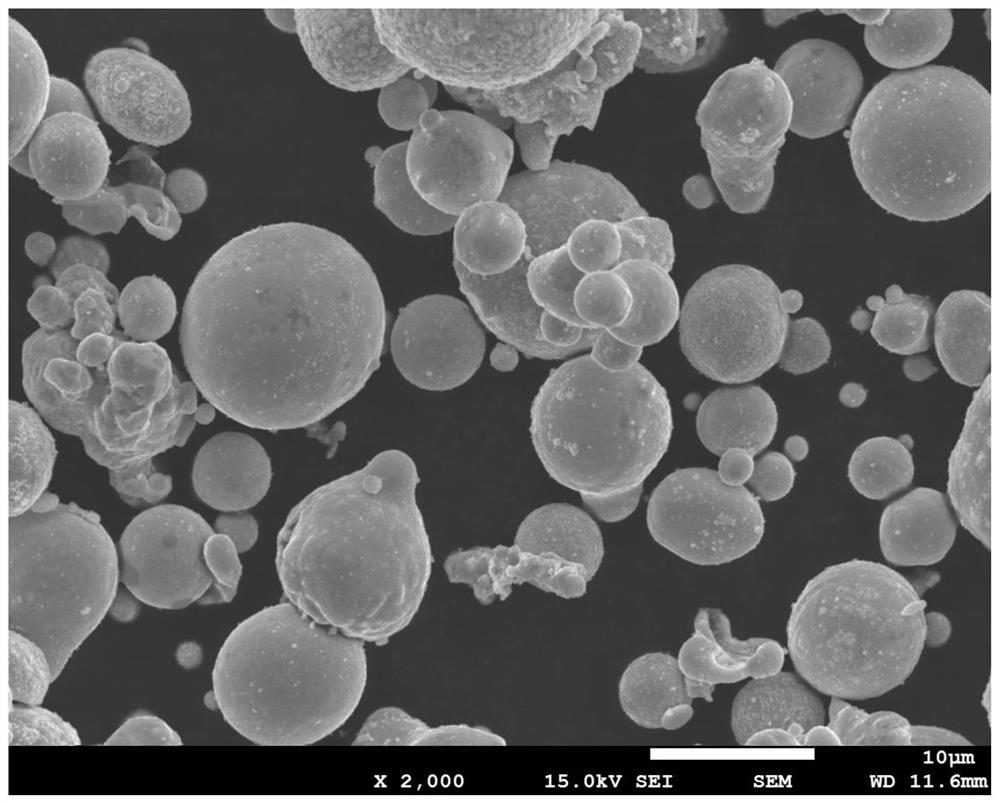

[0052] The titanium carbide-coated high-speed steel composite powder obtained...

Embodiment 3

[0054] This embodiment provides a method for preparing a near-spherical titanium carbide-coated high-speed steel composite powder. figure 1 In the device system shown, the preparation method comprises the following steps:

[0055] (1) The high-speed steel powder with a particle size of 1 μm-30 μm is placed in a fluidized state in the protective atmosphere of the fluidized bed reactor.

[0056] (2) On the basis that step (1) continues to be carried out, the titanium source and the reaction gas are synchronously introduced into the fluidized bed reactor, mixed with the high-speed steel powder, the mixing temperature is 900 ° C, and the mixing time is 120 min. The temperature is 60°C, the gas flow rate is 90ml, and the reaction gas gas flow rate is 260ml.

[0057] (3) After the reaction is completed, gas-solid separation is obtained to obtain titanium carbide-coated high-speed steel composite powder.

[0058] The titanium carbide-coated high-speed steel composite powder obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com