A kind of method of low pressure plasma spraying tin coating

A low-pressure plasma and coating technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem that it is difficult to obtain pure and dense TiN coating, so as to avoid oxidation, improve bonding strength, and process simple effect

Active Publication Date: 2019-10-01

GUANGDONG INST OF NEW MATERIALS

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, although the general plasma spraying process can effectively improve the deposition efficiency of TiN coating, it is difficult to obtain a pure, non-oxidized and dense TiN coating.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

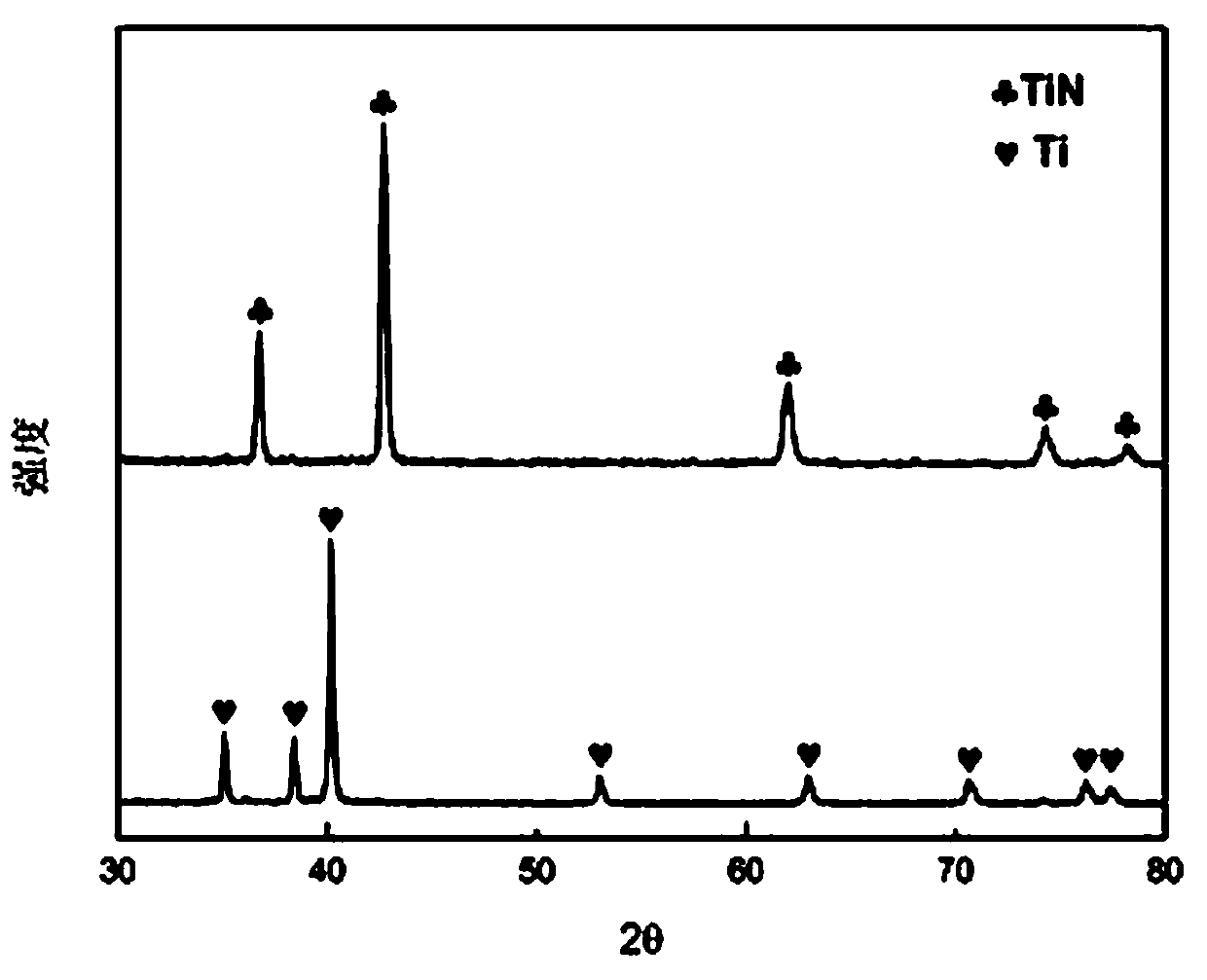

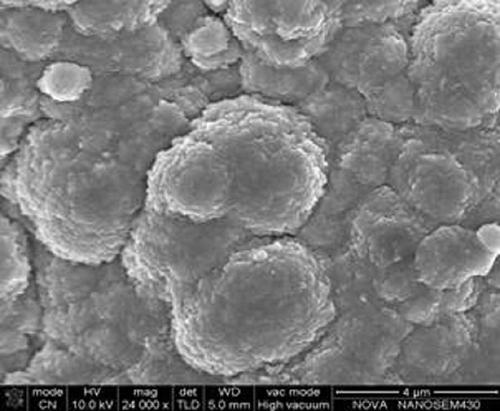

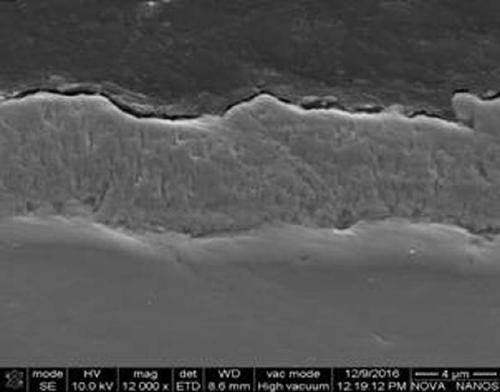

The invention provides a low-pressure plasma spraying method for a TiN coating. The low-pressure plasma spraying method comprises the steps: spraying Ti powder under a low-pressure condition by using a high-power plasma spray gun; and carrying out plasma spray-physical vapor deposition by taking nitrogen as a plasma working gas and a reaction gas to achieve the TiN coating. The TiN coating prepared by using the low-pressure plasma spraying method is of a columnar structure, high in component purity, fine in crystal grain, dense in structure and capable of effectively improving the performance of the surface of a workpiece. A nitriding layer exists between the coating and the workpiece, so that the bonding strength of the coating and the workpiece can be effectively improved. The low-pressure plasma spraying method is simple in process, high in deposition efficiency and suitable for rapidly spraying the TiN coating on a large area.

Description

technical field The invention belongs to the technical field of thermal spraying, in particular to a low-pressure plasma spraying-physical vapor deposition TiN coating method. Background technique As a cermet material, TiN coating has the characteristics of high hardness, high melting point and corrosion resistance, and has been widely used in cutting tools, high-temperature structural materials and anti-wear and anti-corrosion parts. Depositing TiN coating on the surface of titanium and titanium alloys can improve the mechanical properties, corrosion resistance and biocompatibility of the surface, which is beneficial to the application of titanium and titanium alloys in aerospace, ship weapons, petrochemical, biomedical and other fields. Applications. At present, the preparation of TiN coatings at home and abroad generally adopts coating processes, such as physical vapor deposition and chemical vapor deposition. These methods produce pure, dense TiN coatings. However, i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23C4/134C23C4/10C23C4/02

Inventor 刘敏宋琛廖汉林邓春明周克崧邓子谦毛杰邓畅光牛少鹏

Owner GUANGDONG INST OF NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com