Amplitude descending screening method and vibrating screen

A vibrating sieve and amplitude technology, which is applied in the direction of vibrating fluid, sieving, and solid separation, can solve problems such as uneven distribution, affecting the processing capacity and screening efficiency of the vibrating screen, and unfavorable development of large-scale vibrating screens. The material layer is uniform and stable, the screening efficiency is high, and the force condition is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

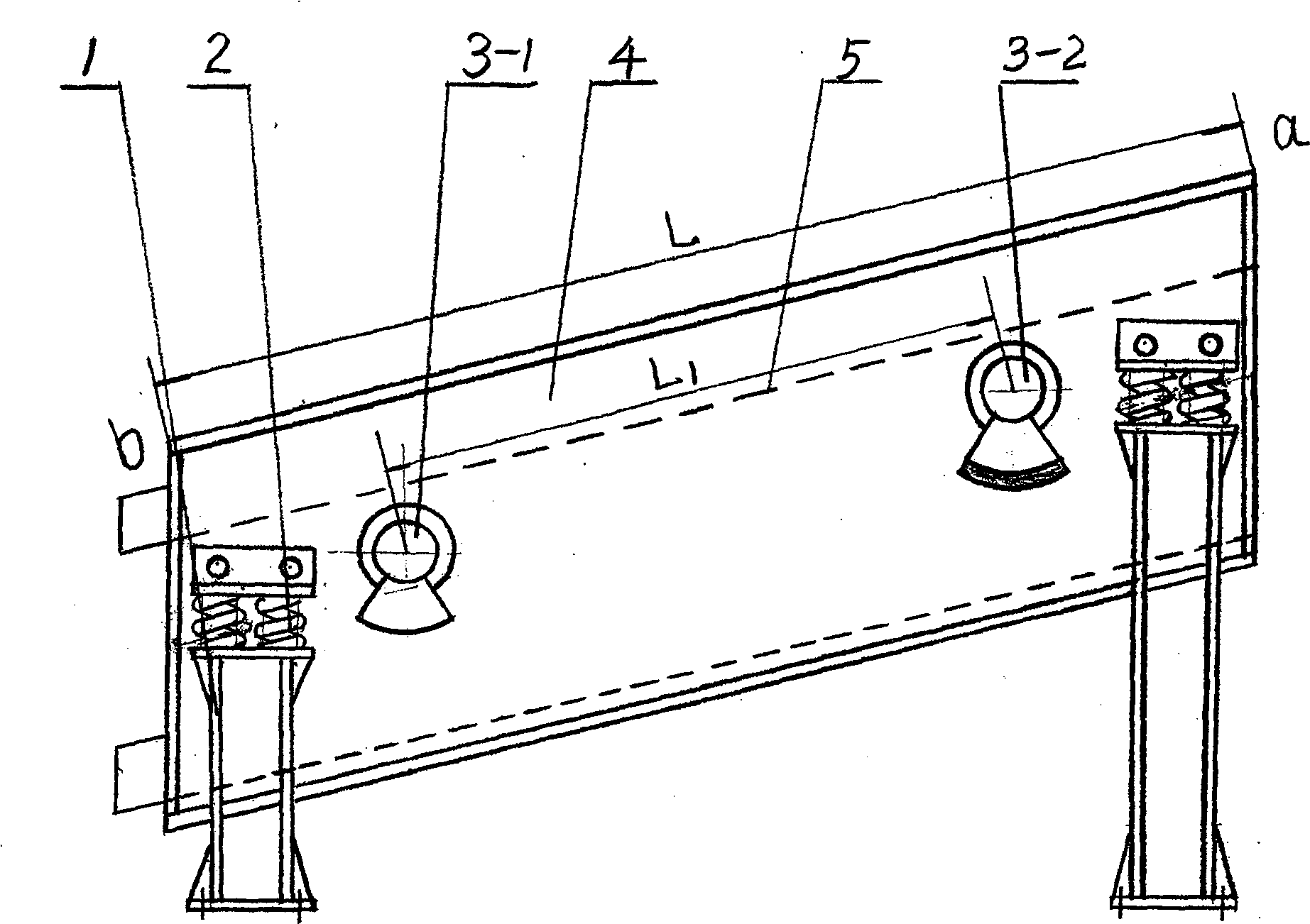

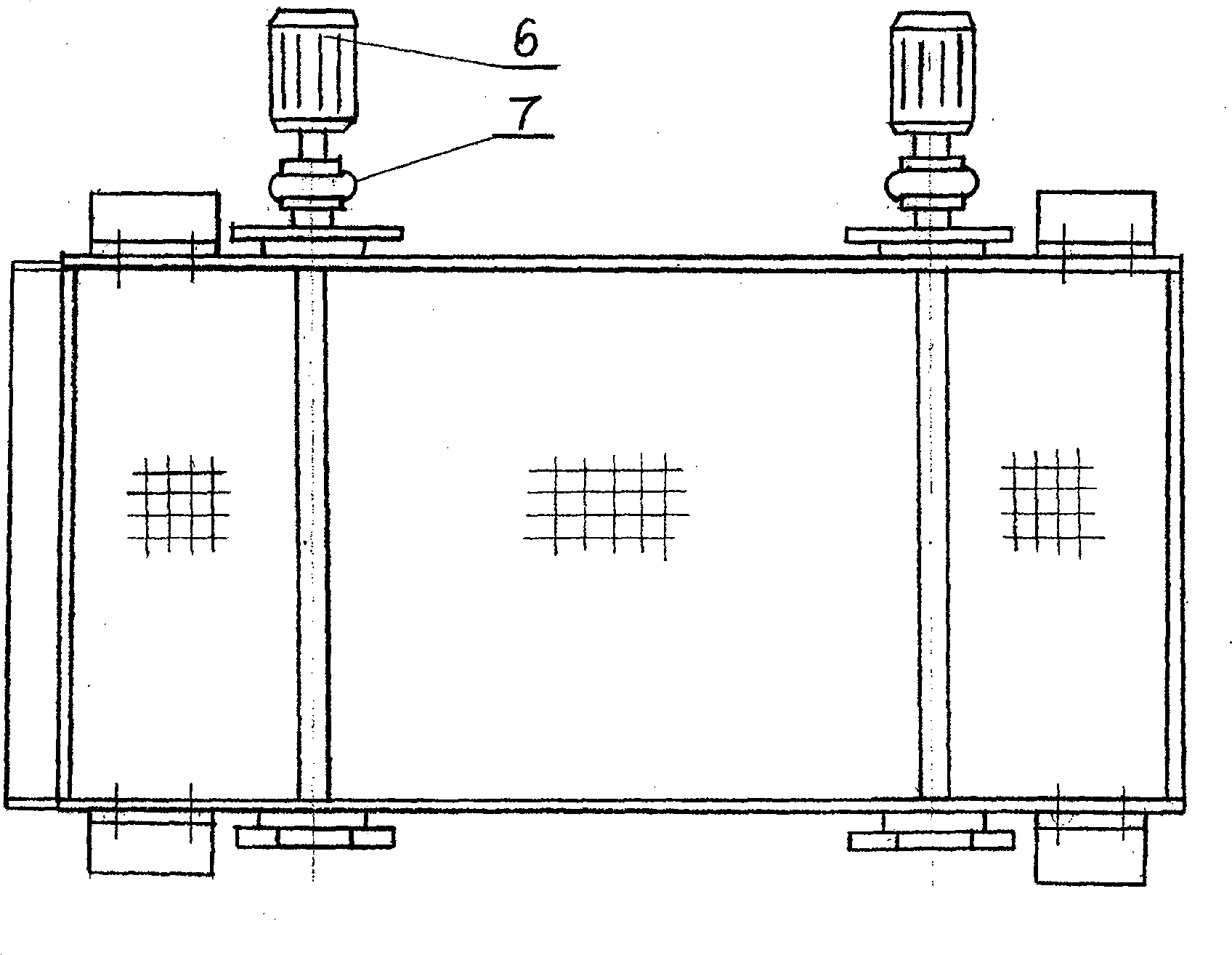

[0011] Now illustrate an embodiment of the present invention in conjunction with accompanying drawing. Vibrating screen of the present invention is made up of support 1, damping spring 2, screen box 4, screen cloth 5, motor 6 and vibrator 3-1, 3-2 etc. The screen box 4 of the vibrating screen is installed on the machine base 1 through the vibration damping spring 2, and the screen mesh 5 is installed in the screen box 4; a is the feeding end, b is the discharging end, and the two vibrators 3-1 and 3- 2 are respectively installed at the discharge end and the feed end of the screen box 4. The screen box 4 has a length of 8.2 meters and a width of 3.8 meters. The eccentric parts of the two vibrators are different, the eccentric mass of the vibrator 3-2 at the feed end is 5kg more than that of the vibrator 3-1 at the discharge end, and the distance between the centers of the two vibrators is 4.5 meters. The motion trajectory of the screen box is elliptical. The amplitude (major ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com