Automatic screw and filling piece compounding device

An automatic combination and gasket technology, which is applied to threaded products, metal processing equipment, and other manufacturing equipment/tools, can solve the problems of large occupied area and complex structure, and achieve space saving, compact overall structure, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

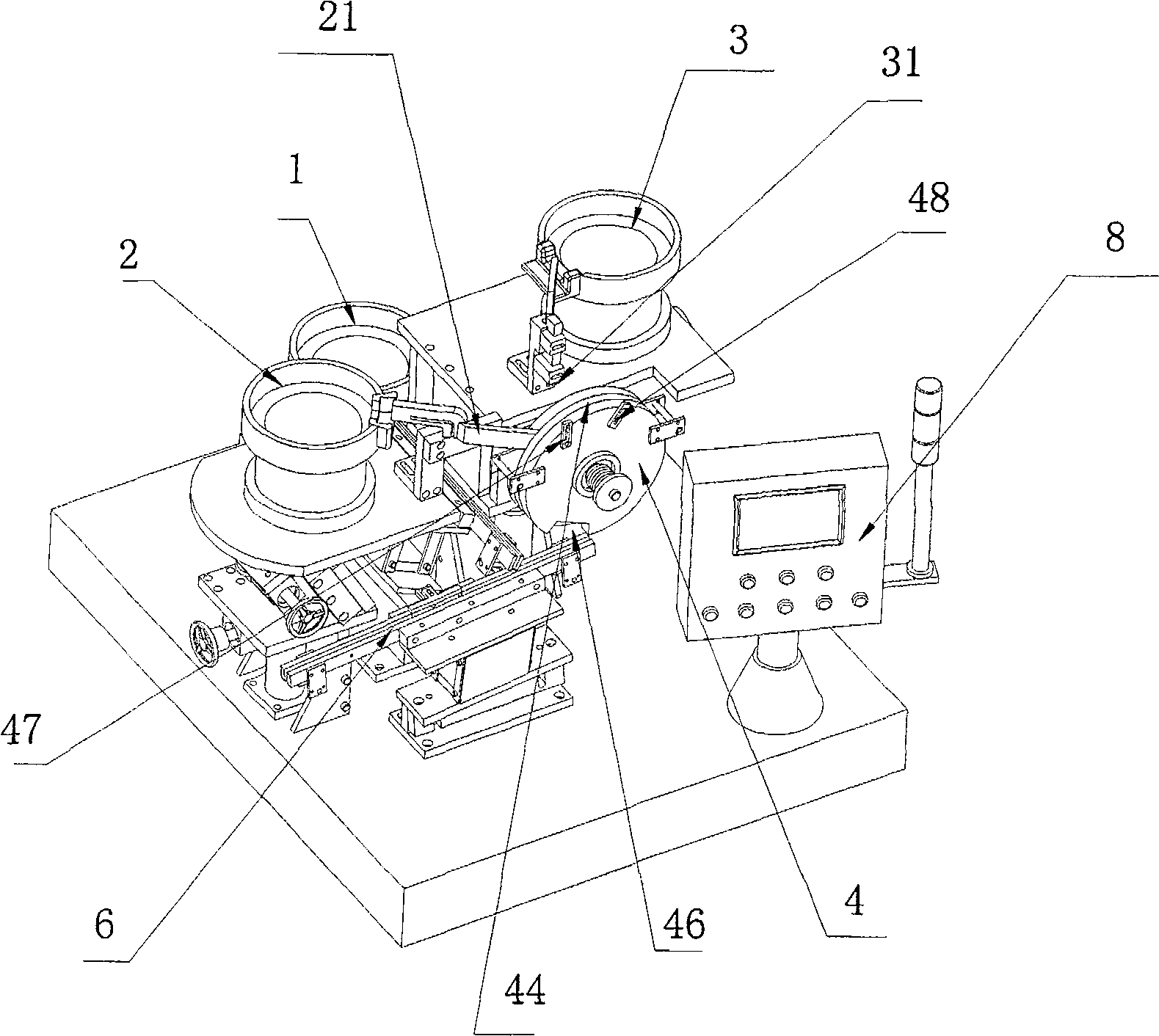

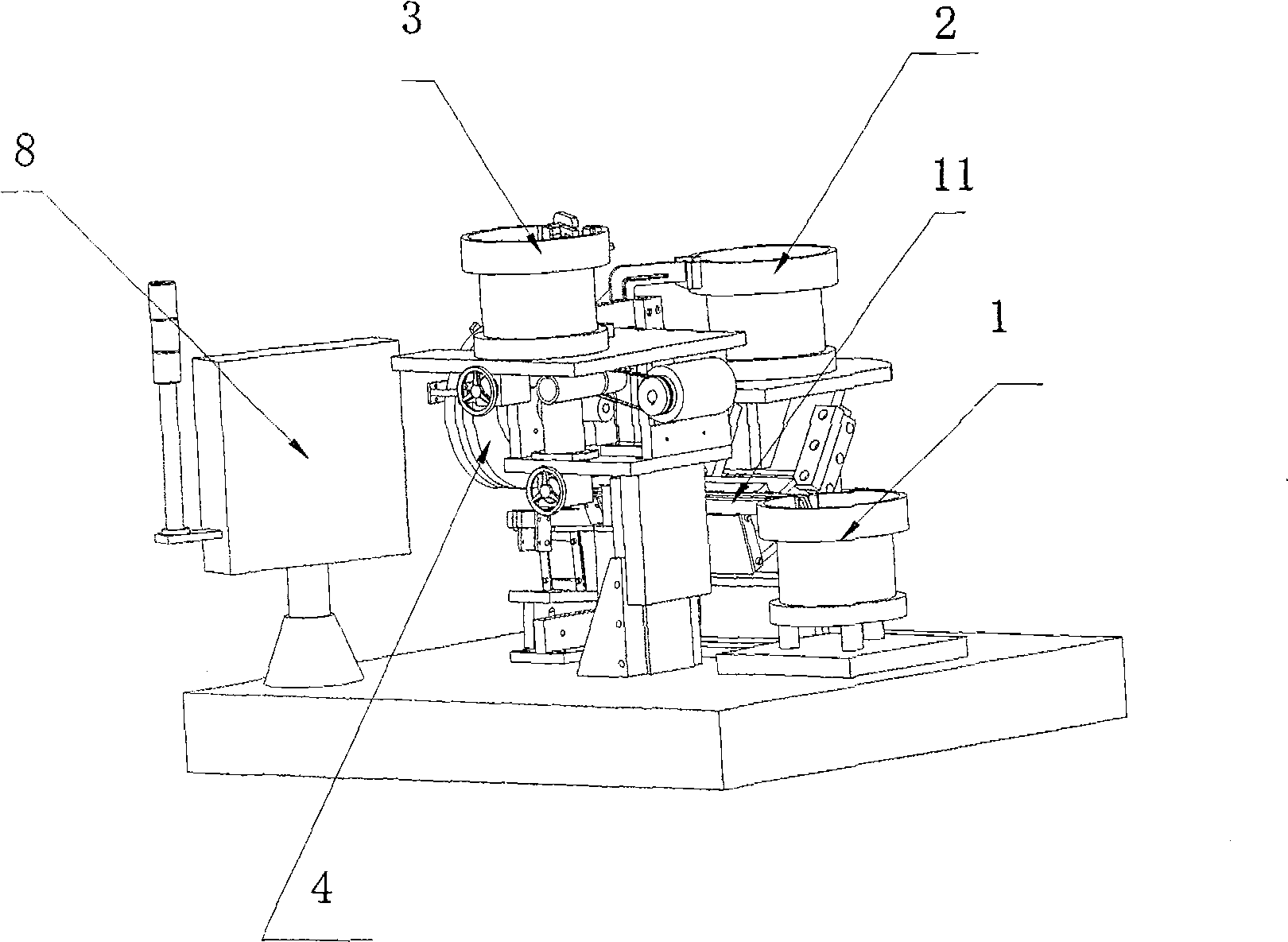

[0053] Such as figure 1 and figure 2 As shown, the present invention includes a main part vibrating plate 1 , a main part unloading bridge 11 , a first gasket vibrating plate 2 , a first pad unloading bridge 21 , a hanger 4 , a blocking plate 5 and a direct vibrating bridge 6 .

[0054] The main part vibration plate 1 and the main part unloading bridge 11 are located on one side of the feeder 4, and the main part unloading bridge 11 is responsible for transferring the vertically arranged main parts after being vibrated by the main part vibrating plate 1 to the feeder The feeding port 46 of 4; the first gasket unloading bridge 21 and the hanger 4 are located in the same vertical plane, which is responsible for conveying the gaskets vibrated by the first gasket vibrating plate 2 and feeding them into the hanger 4. Hanging the main part; the hanger 4 is set perpendicular to the workbench, it is responsible for transporting the main part (screw or steel nail) and the gasket, and...

Embodiment 2

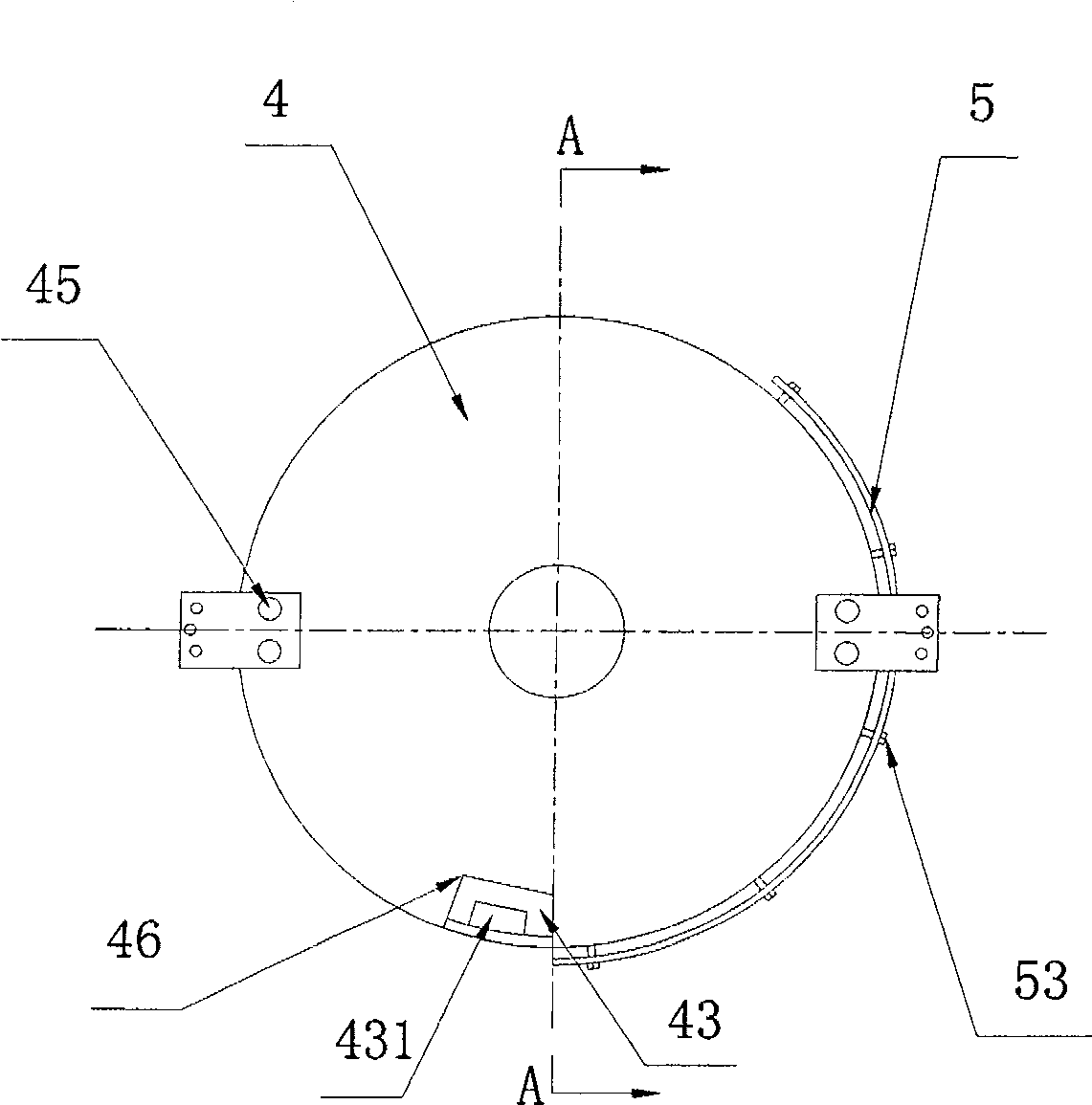

[0064] When two gaskets need to be inserted sequentially on the main part, two unloading bridges can be arranged radially on the upper half circumference of the hanger 4 .

[0065] Such as figure 1 and figure 2 As shown, the present invention further includes a second pad vibrating plate 3 and a second pad blanking bridge 31 on the basis of the first embodiment.

[0066] The second gasket vibrating plate 3 is located on one side of the material hanger 4, and the second gasket blanking bridge 31 is located in the same vertical plane as the material hanger 4, and is along the same vertical plane as the first gasket blanking bridge 21 in this plane. The positive direction of rotation of the material hanging tray 43 is arranged front and back. The second gasket unloading bridge 31 is responsible for conveying and feeding the gaskets vibrated by the second gasket vibrating plate 3 to the main part on the hanger 4 . The second gasket lowering bridge 31 is arranged on the upper h...

Embodiment 3

[0071] On the basis of foregoing embodiment, the present invention can carry out following improvement:

[0072] Such as Figure 6 , Figure 7 As shown, the second bolt 53 is flexibly connected between the blocking piece 5 and the hanger 4 . When the number of shims inserted is large, or the shims are thick, the distance between the blocking piece 5 and the side wall of the hanger 4 can be adjusted through the second bolt 53 .

[0073] The working process is the same as the previous embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com