Laminated element provided with a heated layer

A technology of multi-layer components and covering layers, applied in heating methods, electrical components, ohmic resistance heating, etc., can solve problems such as deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

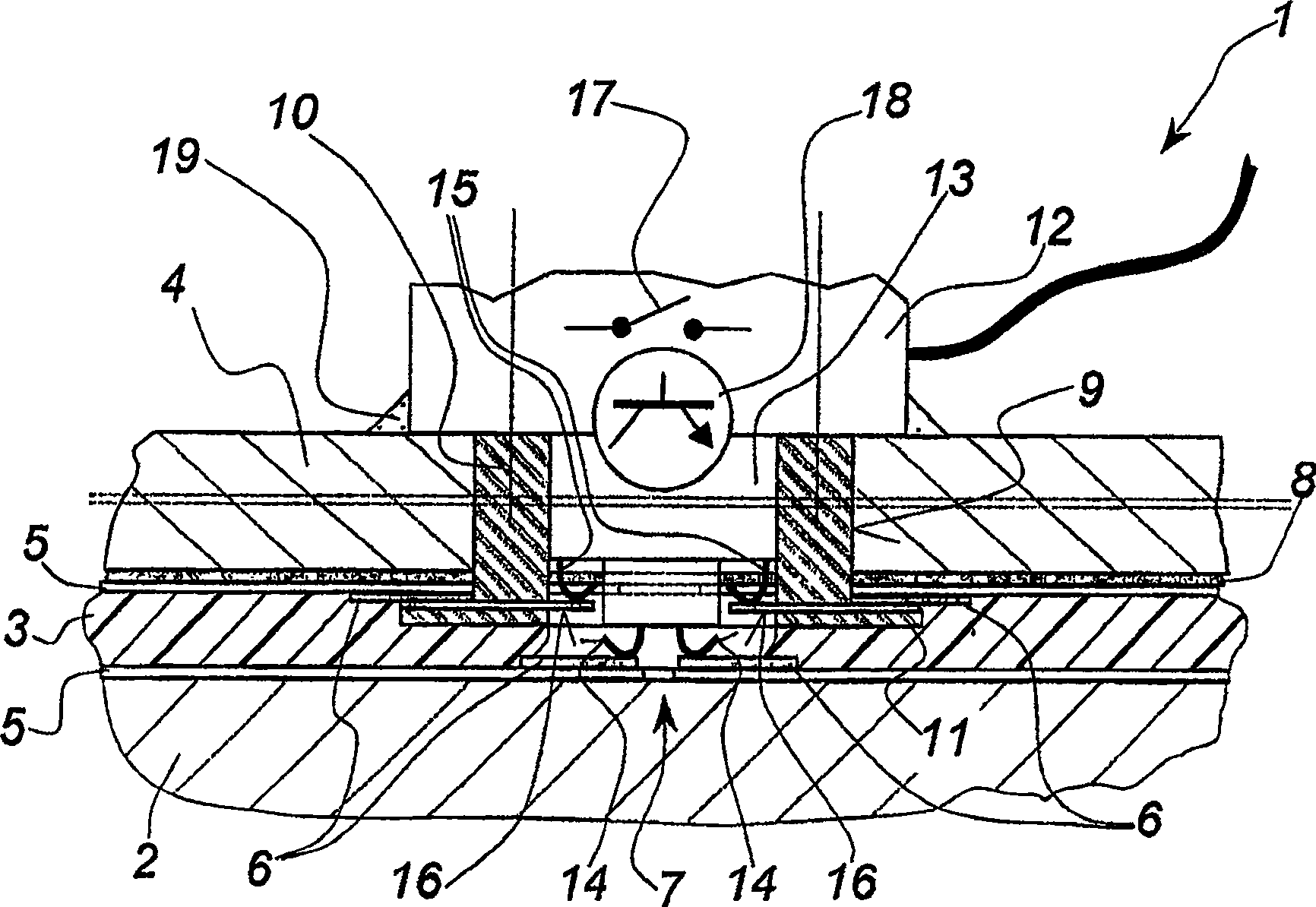

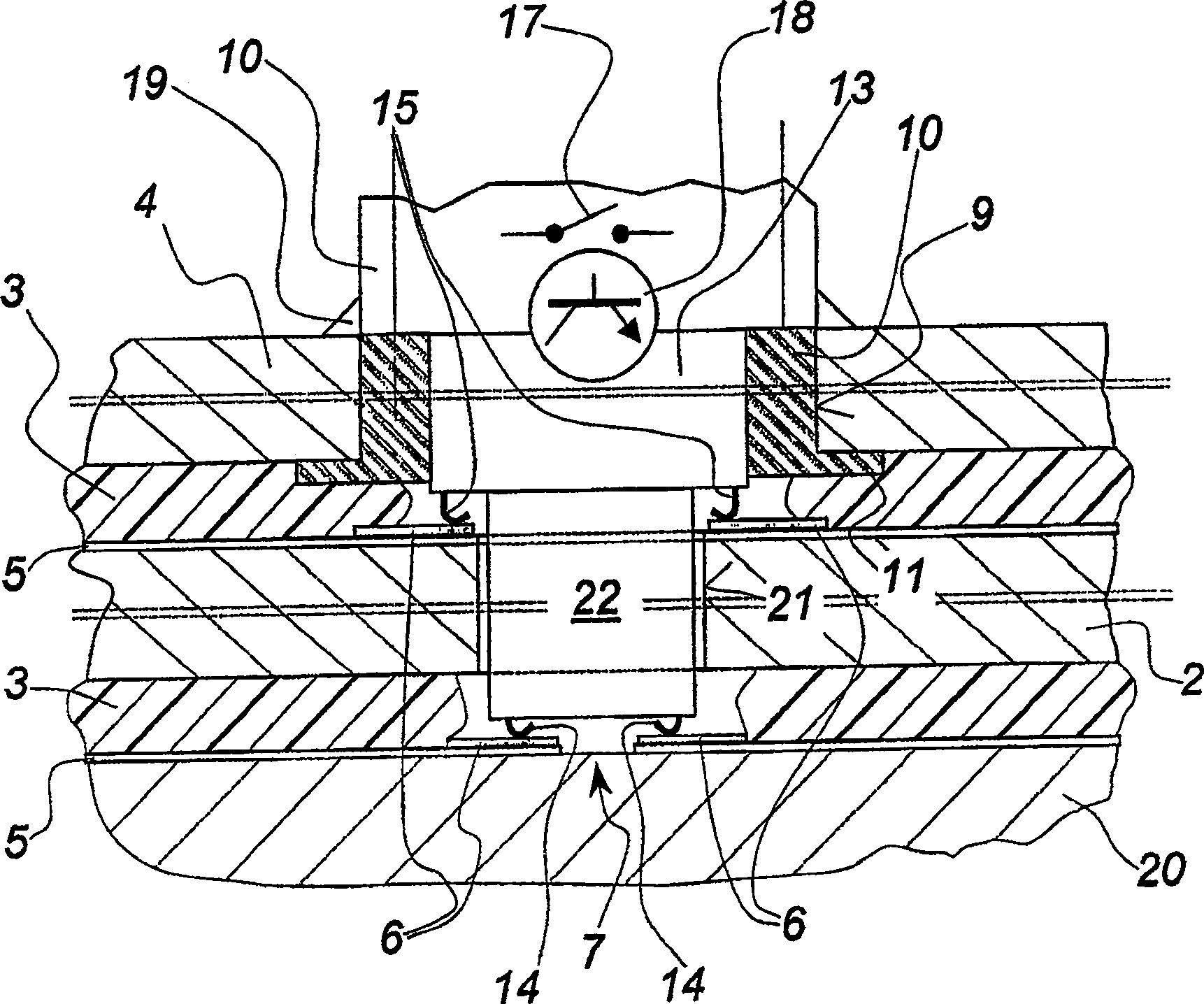

[0033] exist figure 1 Here, the plate-shaped heating element 1 according to the invention is implemented in the form of a multi-glazed window with a first rigid pane 2 , an adhesive layer 3 and a second rigid pane 4 . Said rigid panes 2 and 4 are preferably preheated or partially prestressed panes. On the flat side facing the adhesive layer 3 each pane is provided with a heating layer 5 . Only a portion of the thickness of the rigid glazing 2 is shown and the dashed double line through the rigid glazing 4 indicates that the shown thickness is shortened. It can be understood that the two rigid panes are thicker than the adhesive layer 3 .

[0034] Said heating layer 5 comprises a composition and / or a continuous layer sufficiently resistant to thermal stresses and adapted to the particular application and possibly to the prestressing of said glazing when used as a surface heating layer. Suitable layer systems are described in the prior art in a number of variants, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com