Device for the production of plastic containers by means of stretch blow moulding and device for coating the inner walls of a plastic container

A plastic container and stretching technology, which is applied in the direction of spraying device, liquid spraying device, metal material coating process, etc., can solve the problems of complex structure, large size and failure to meet the quality requirements of the distributor block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

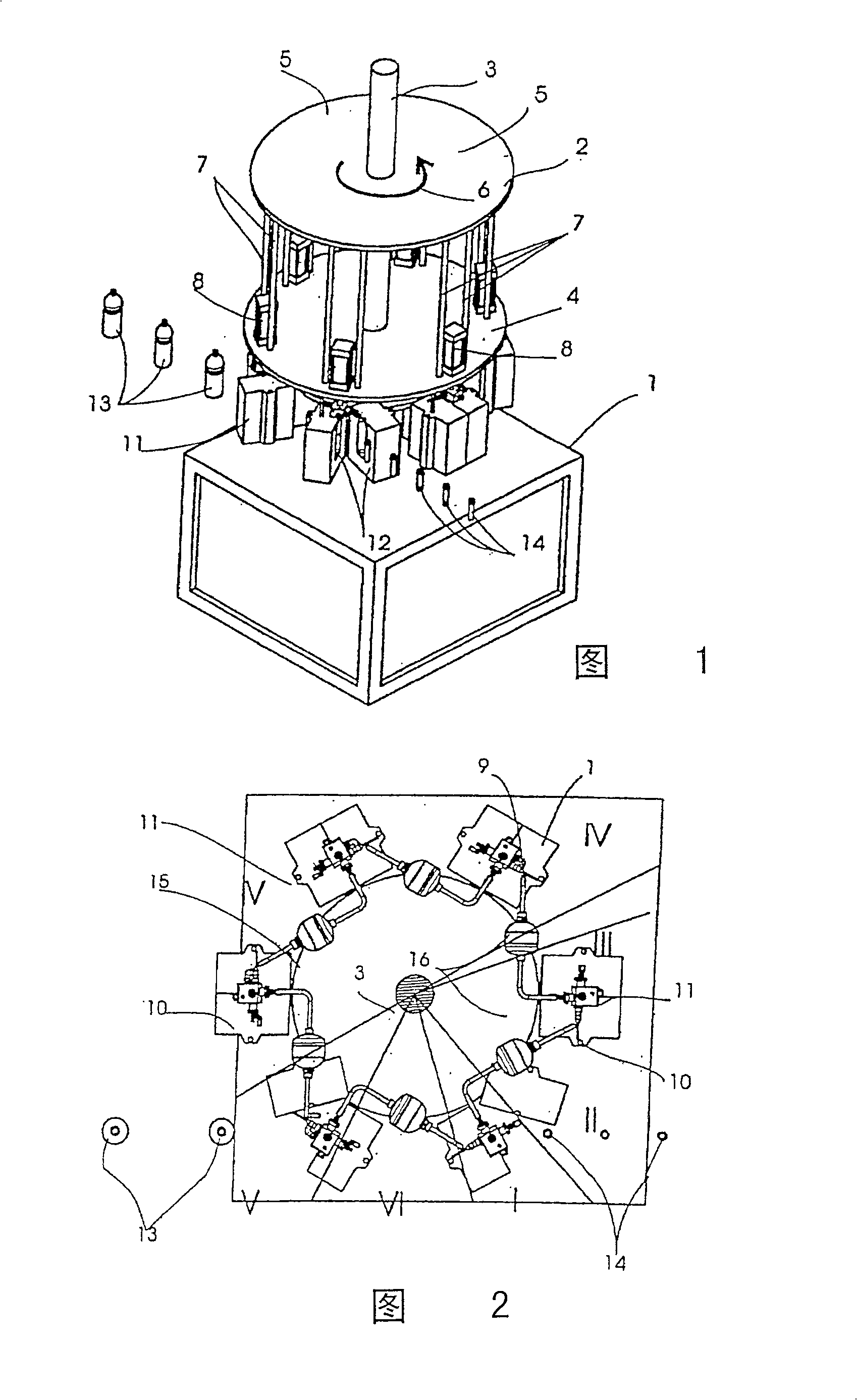

[0081] figure 1 An industrial circular rotary machine with six coating units is shown in . Supported on a schematically represented frame table 1 is a rotating conveyor 2 about a drive shaft 3 with a circular base plate 4 and a concentric cover plate 5 . Viewing the frame table 1 in the downward direction of the drive shaft 3, the rotating conveyor 2 is driven during operation in an anticlockwise direction corresponding to the arrow direction 6 (direction of rotation) at a constant angular velocity.

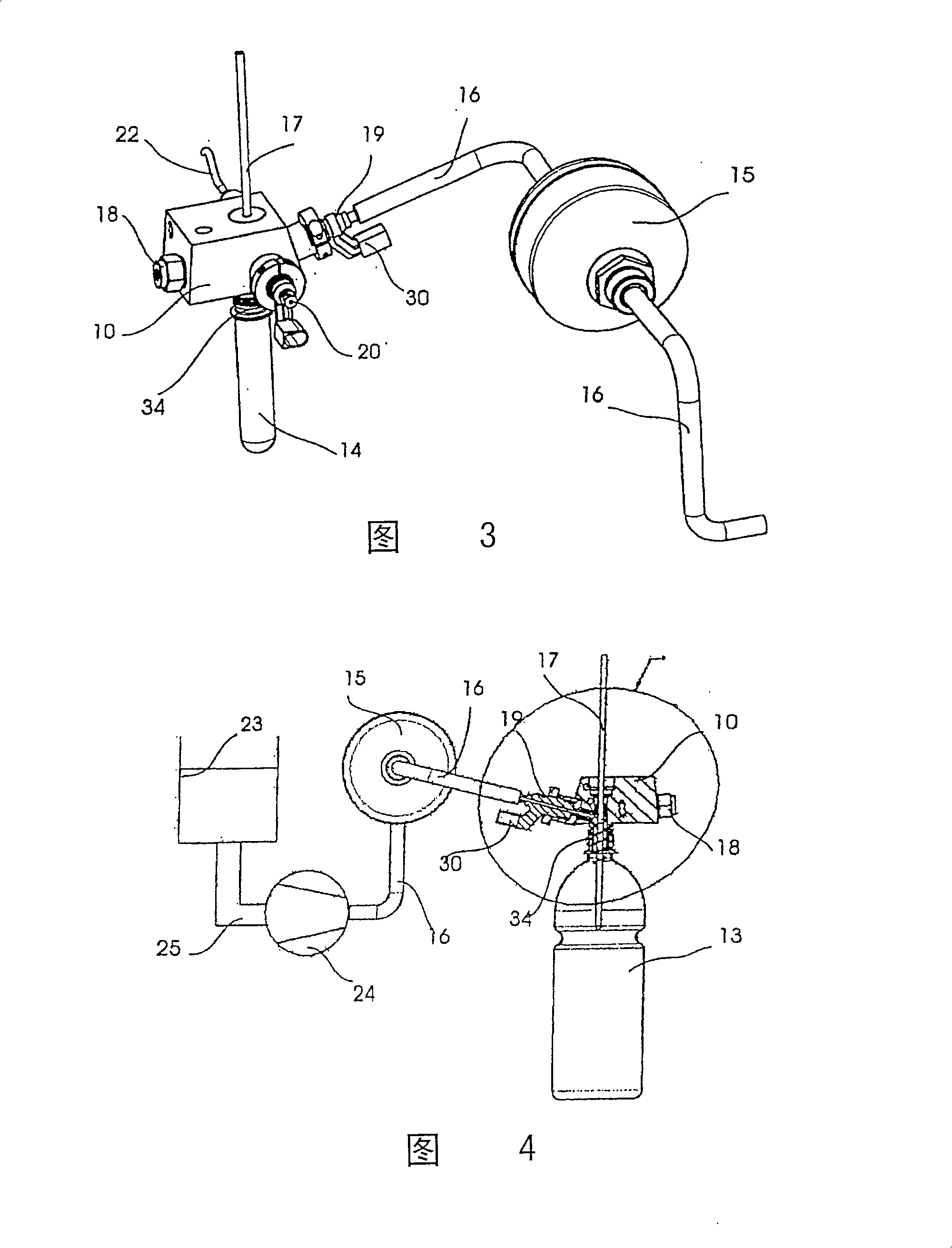

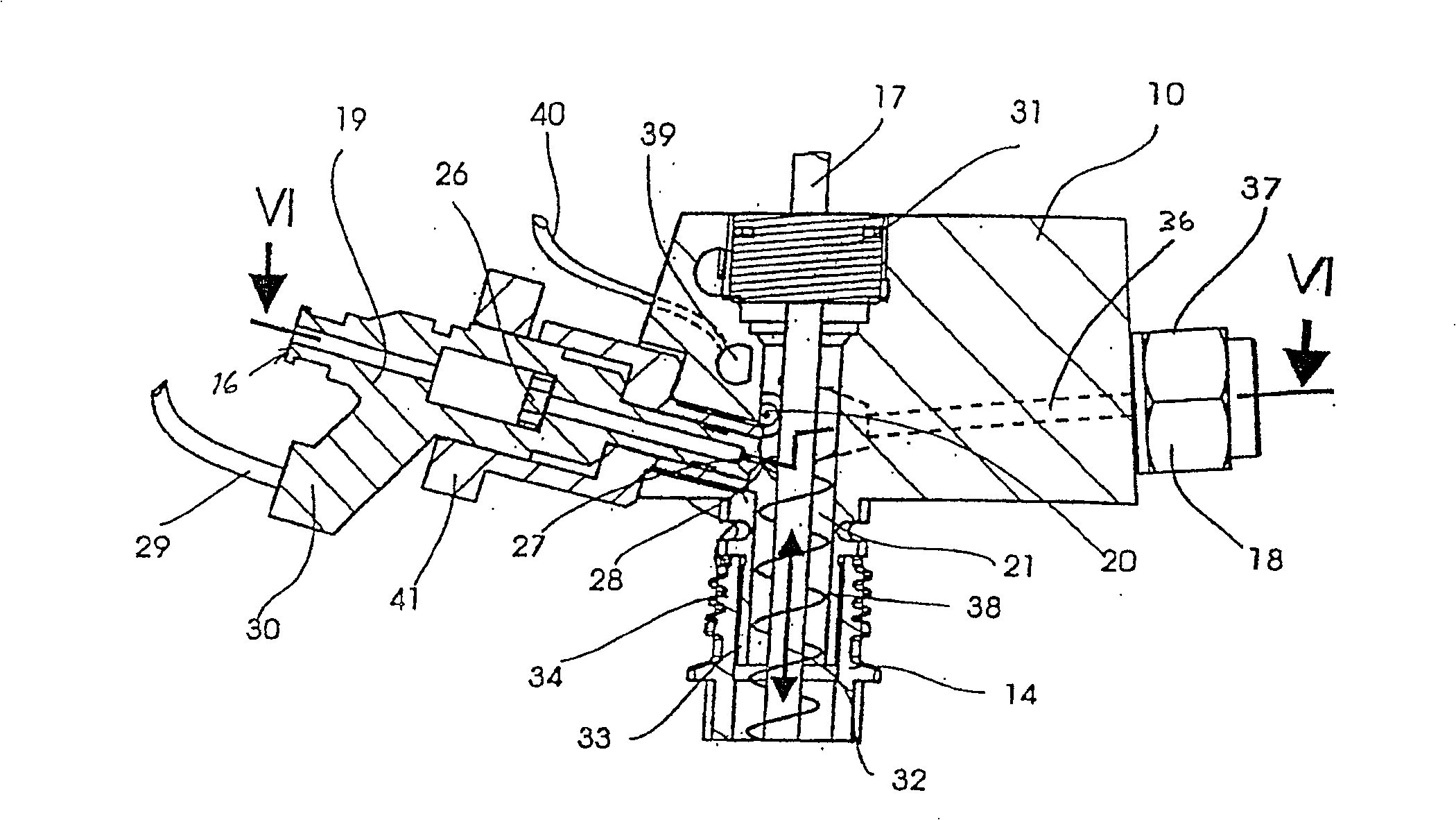

[0082] Distributed over the periphery, the lower base plate 4 carries pairs of vertical support rods 7, while mounted between each two support rods 7 are corresponding columns 8 for tensioning the plungers ( will be described below). The rotating conveyor 2 carries six application devices 9 , for which purpose six pairs of vertical support rods are shown, which connect the bottom plate 4 to the cover plate 5 . A plurality of distributor blocks 10 arranged below with stretch bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com