Apparatus and method for handling lens carriers

A carrier and lens technology, applied in optical elements, optical components, glasses/goggles, etc., can solve the problems of complex lens quantity, limitation, over-complex design and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

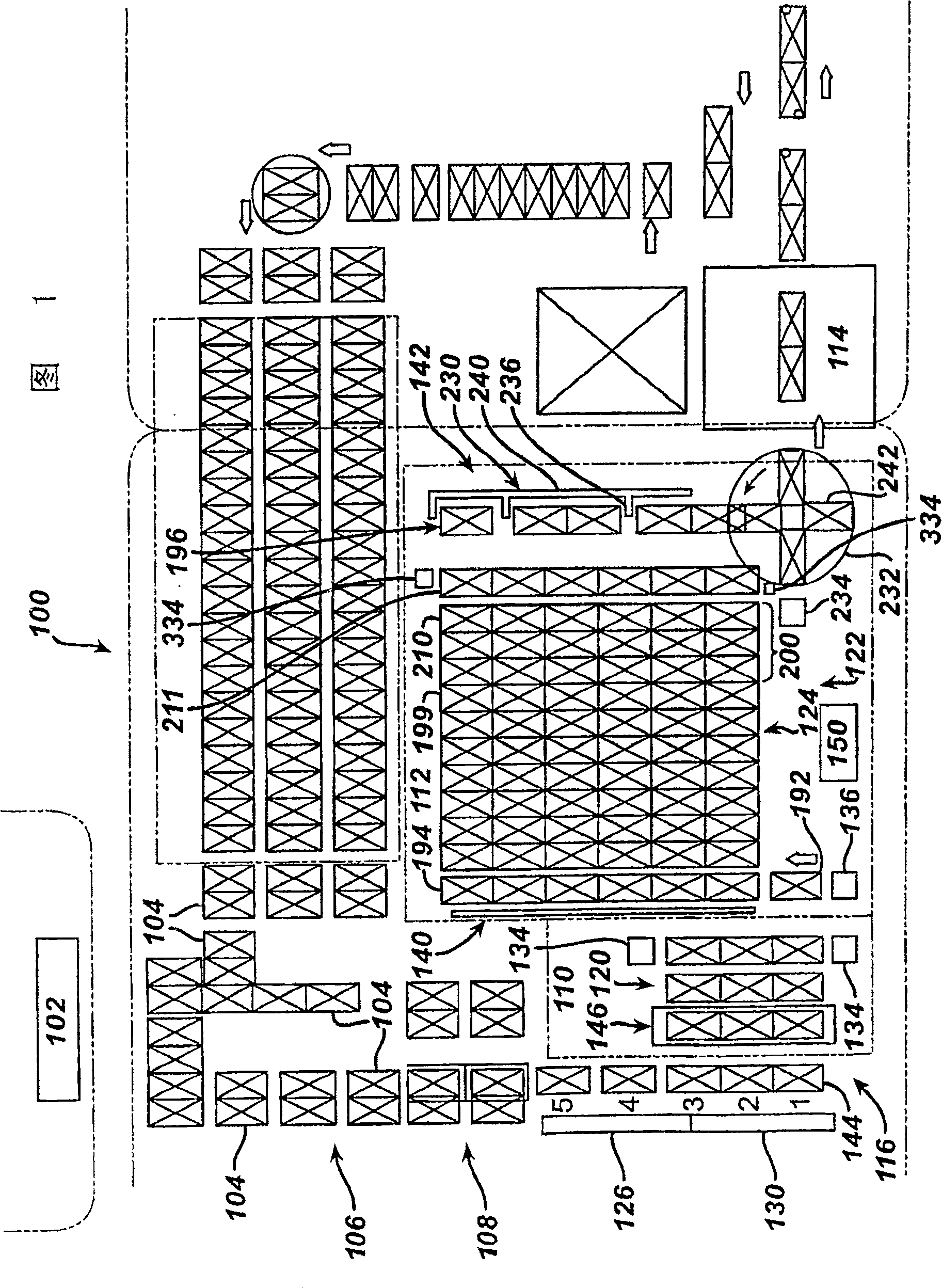

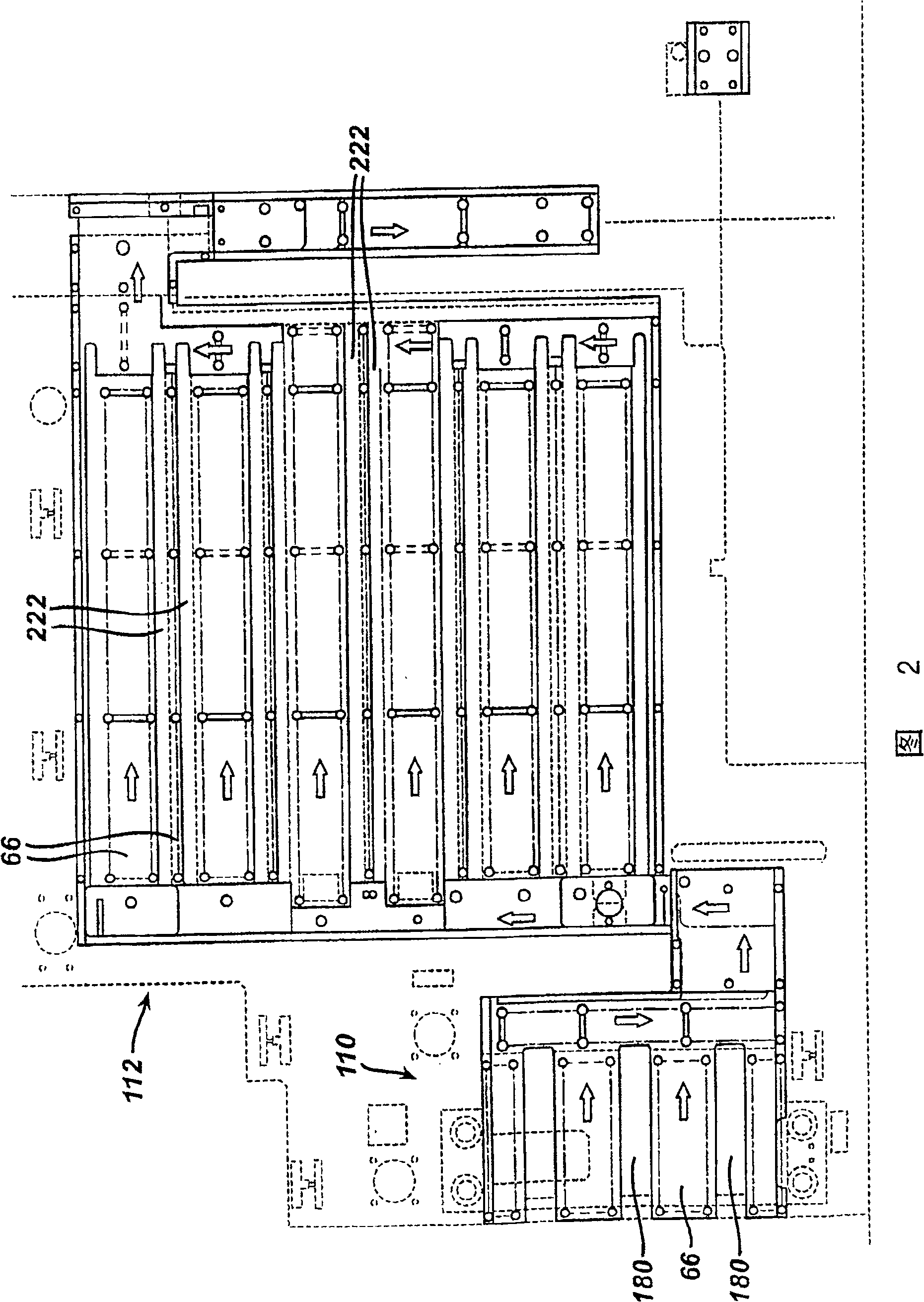

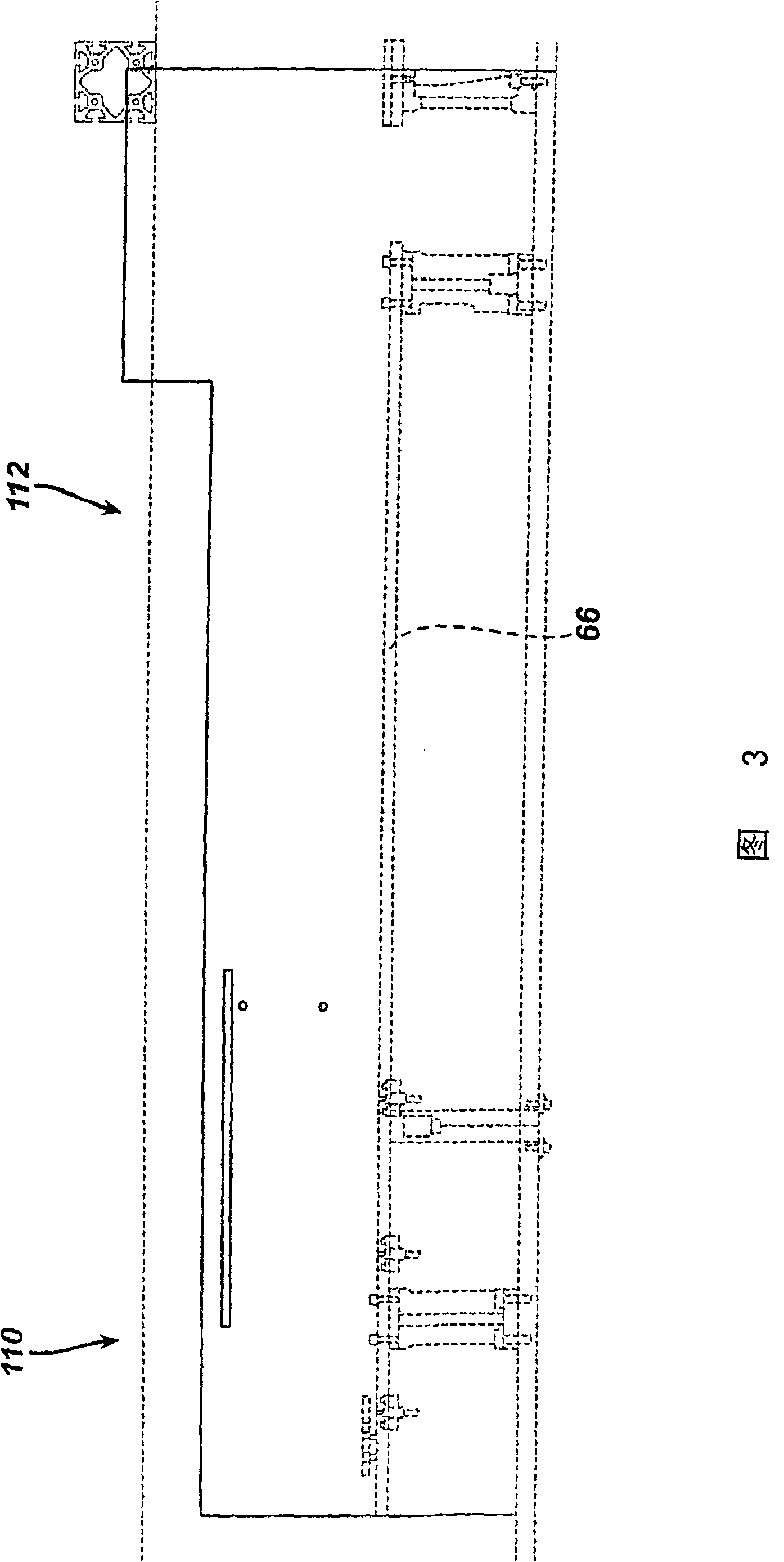

[0023] figure 1 Generally shown is a system 100 for making soft contact lenses from a polymerizable monomer or monomer mixture. Soft contact lenses are formed in a mold assembly having a first female mold half and a second male mold half. The mold half itself is molded in an injection molding machine, indicated schematically at 102, and formed of polystyrene transparent to visible and ultraviolet light. The mold is thin enough to transmit heat quickly and rigid enough to withstand the breakaway forces applied to the separated mold halves during demolding.

[0024] From the injection molding machine 102 , the mold halves are stored in a tray member or carrier 104 . In particular, the front mold half is placed in a first set of carriers and the second mold half is placed in a second set of carriers, each carrier being designed to accommodate a number of mold halves, for example eight; After molding, the carriers are conveyed from the injection molding area. Then, in a dosing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com