Extruded plastic cooling device

A technology for plastics and strips, applied in the field of extrusion plastic production equipment, can solve problems such as increasing costs, increasing operating steps, lengthening production lines, etc., and achieving the effects of increasing the floor space, enhancing the cooling effect, and prolonging the cooling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

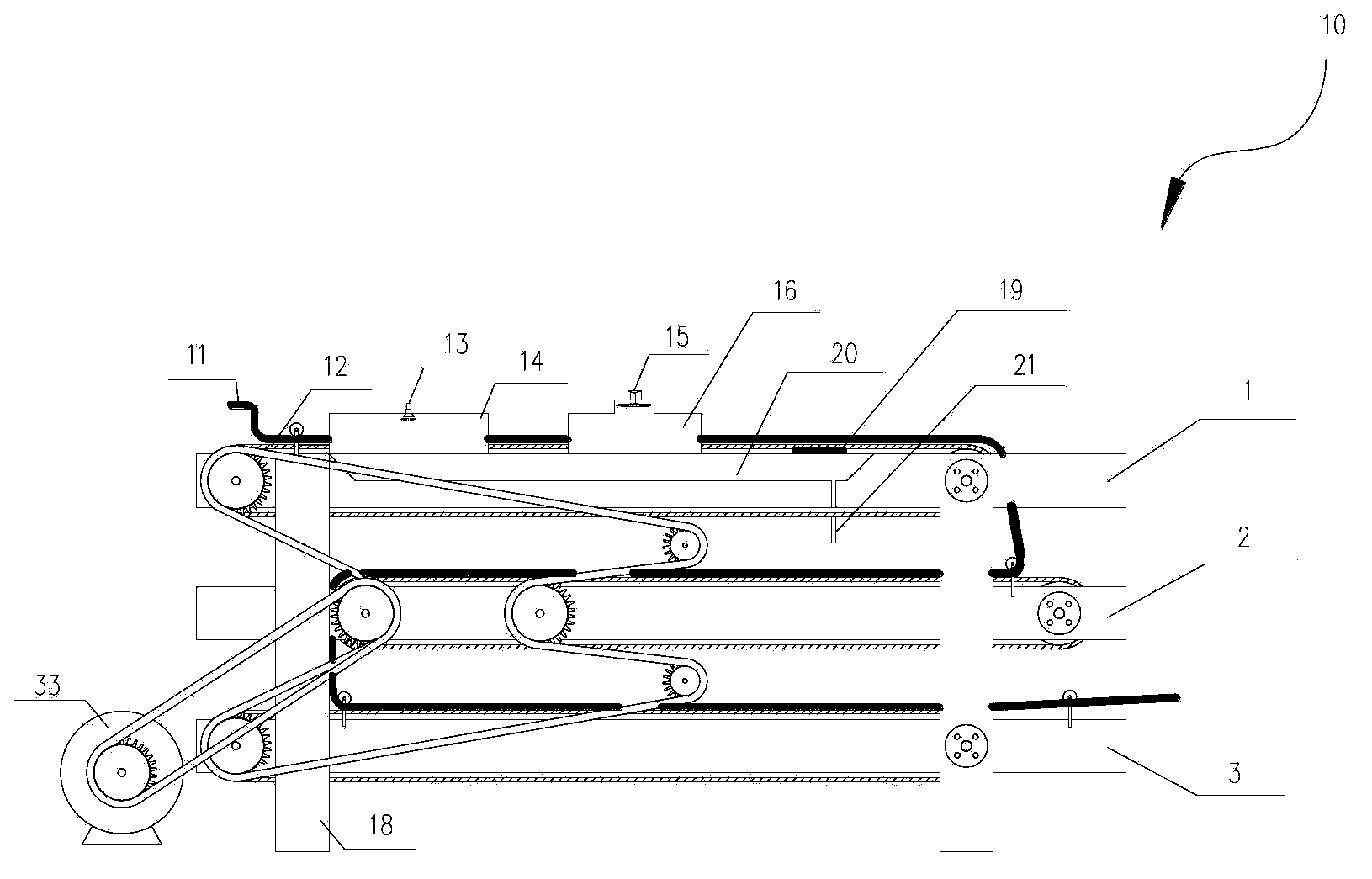

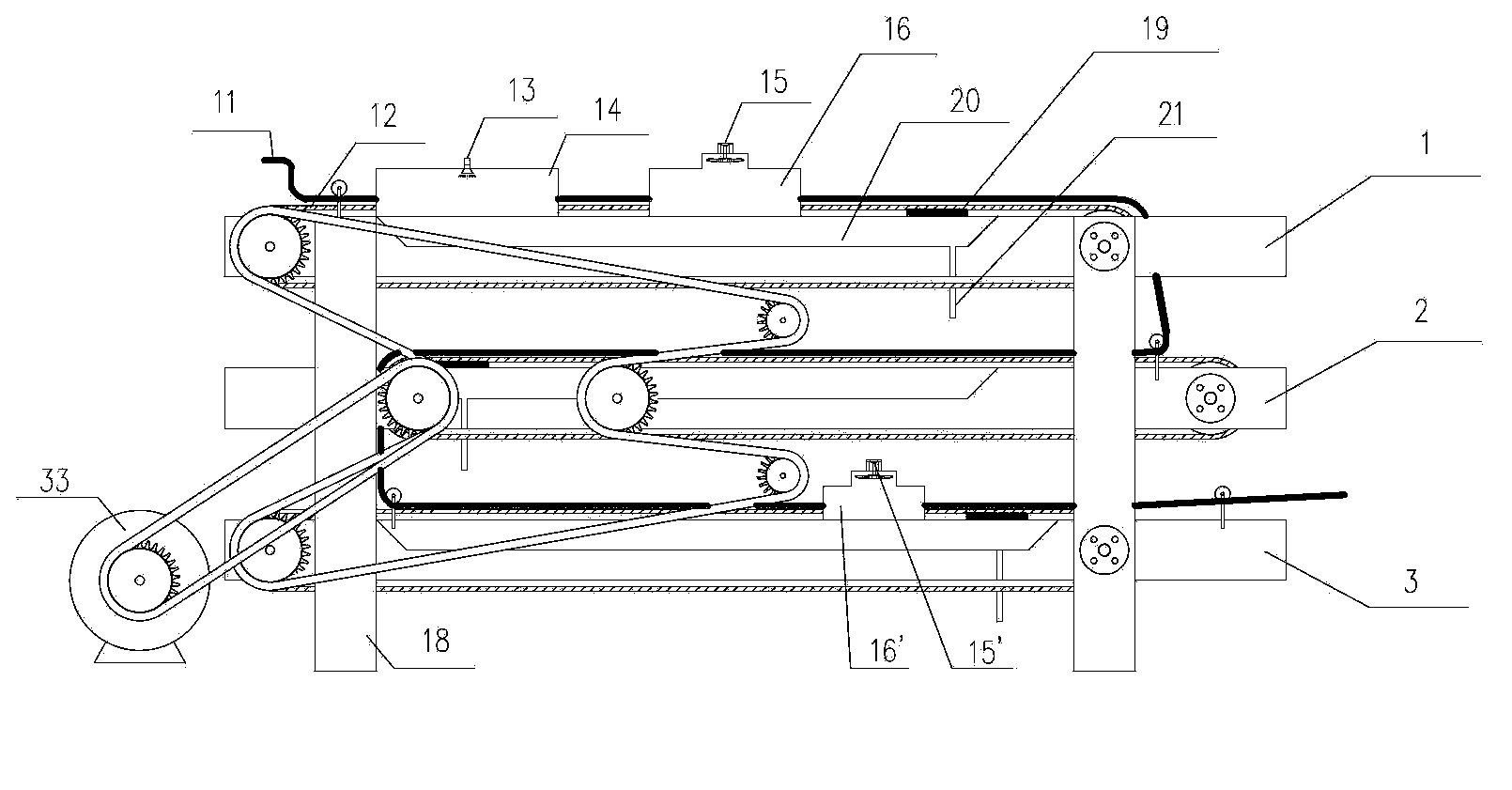

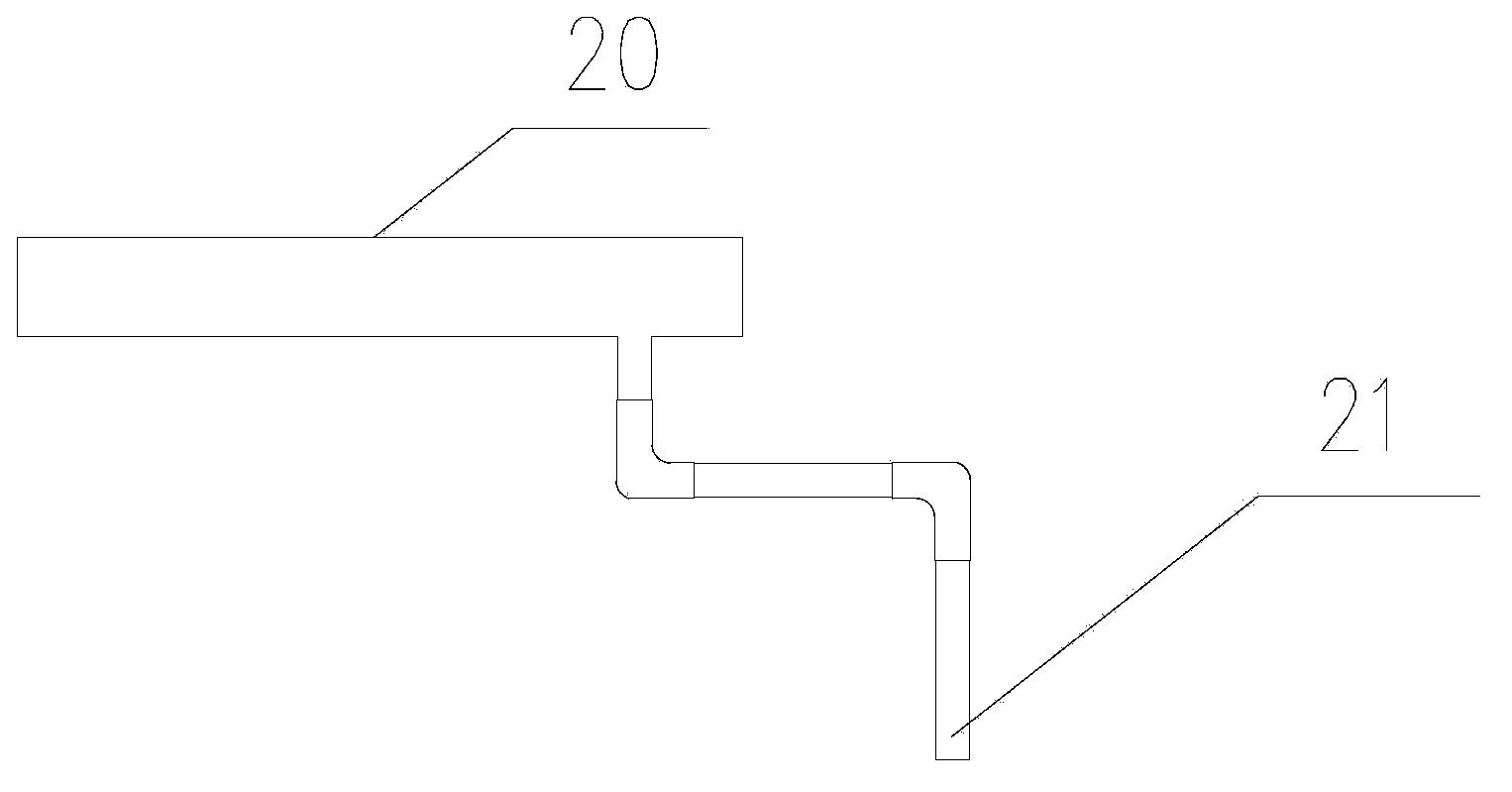

[0032] figure 1 A first embodiment of a device 10 for cooling extruded plastics according to the invention is shown schematically. The device 10 for cooling extruded plastics includes a frame 18 on which a plurality of horizontal conveyor belts 12 for conveying material strips 11 and a drive mechanism for the conveyor belts 12 are arranged. In order to reduce the footprint of the device 10 , a plurality of conveyor belts 12 can be vertically arranged on the frame 18 . The device 10 for cooling extruded plastics is also fixedly provided with a plurality of fluid injectors 13 with nozzles facing the conveyor belt, and a fluid collection tank 20 is provided below the conveyor belt 12 adjacent to its conveying surface. In the process of conveying the material strip, the fluid injector 13 is used to spray fluid to the material strip to cool it, and the fluid collection tank 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com